Reconstructible assembly line balancing optimization method

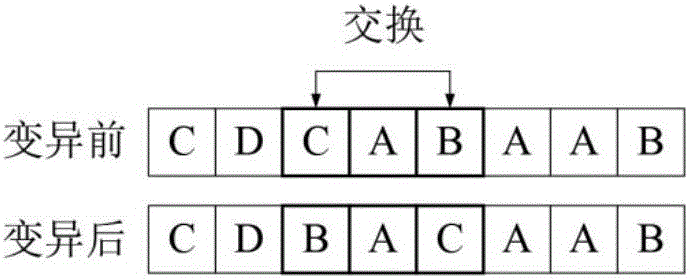

An optimization method and assembly line technology, applied in the fields of genetic laws, instruments, manufacturing computing systems, etc., can solve the problems of poor convergence, low local search ability, low computing efficiency, etc., and achieve the effect of low fitness value and improved optimization ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings.

[0044] These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0045] Classification and description of reconfigurable assembly line balance problem

[0046] Assembly line balance refers to arranging quantitative tasks to a fixed number of workstations under certain constraints, so that the operating time of each workstation can meet the specified beats, and reduce the idling and overload time of workstations. The parameters describing the balance problem of reconfigurable assembly line generally include three types: ① operation element; operation element refers to the smallest operation unit or task in the process of product production and assembly. A job element does not only contain one job action, but also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com