Method for sinter microstructure analysis based on panoramic mineral phase diagram

A technology of microstructure and analysis method, which is applied to the analysis of materials, material analysis through optical means, instruments, etc. It can solve the problems of heavy workload, limited observation field of view, and high price of microscopes, and achieve the effect of improving quality and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

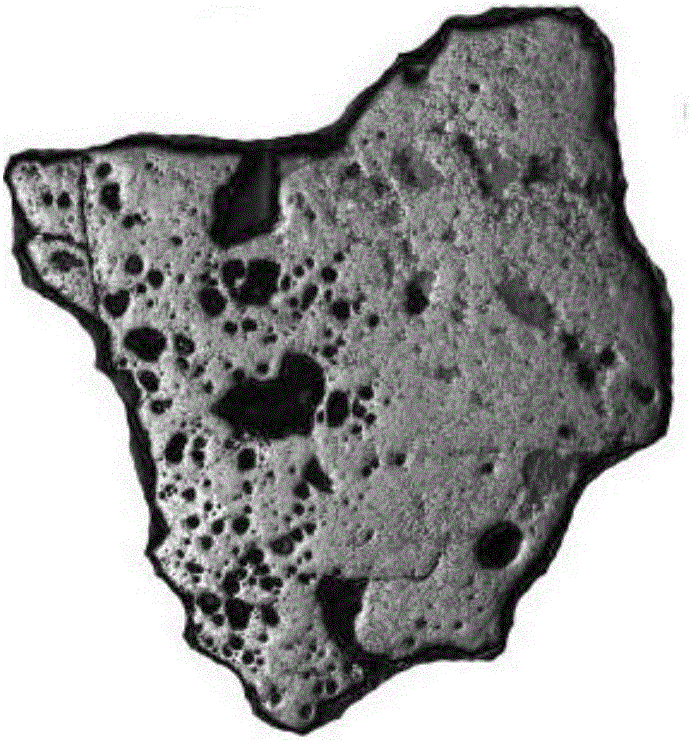

[0053] 1) Sample preparation and polishing. The sintered ore of WISCO was used in this example, and its chemical composition is shown in Table 1. The sample is roughly ground, hot-mounted, polished, dried, and observed under a microscope.

[0054] Table 1 The chemical composition of the iron-containing charge used in the experiment

[0055] Mineral

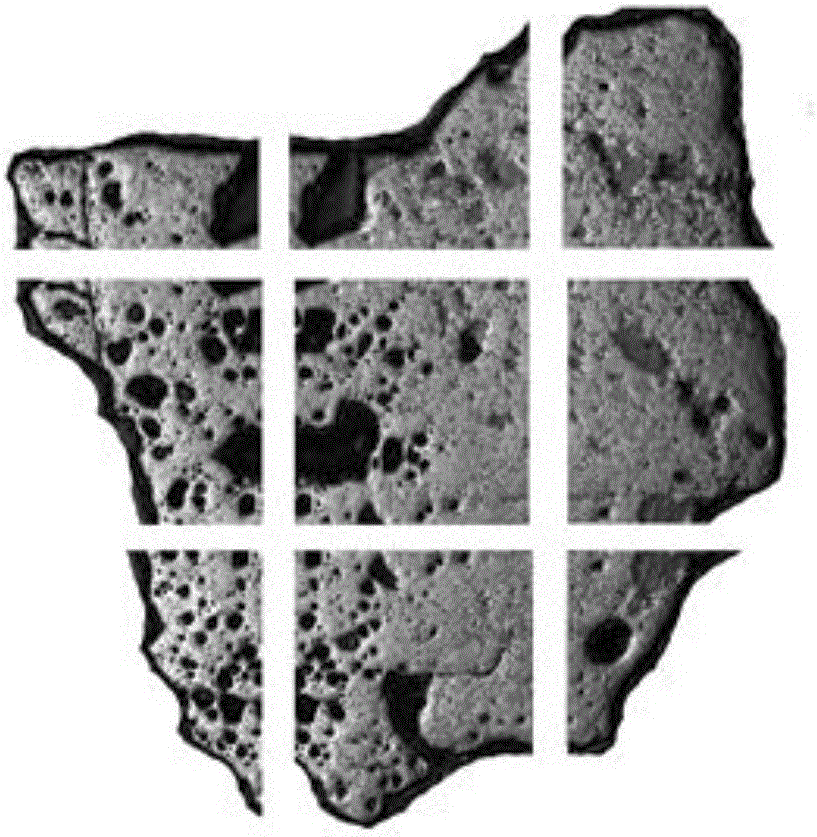

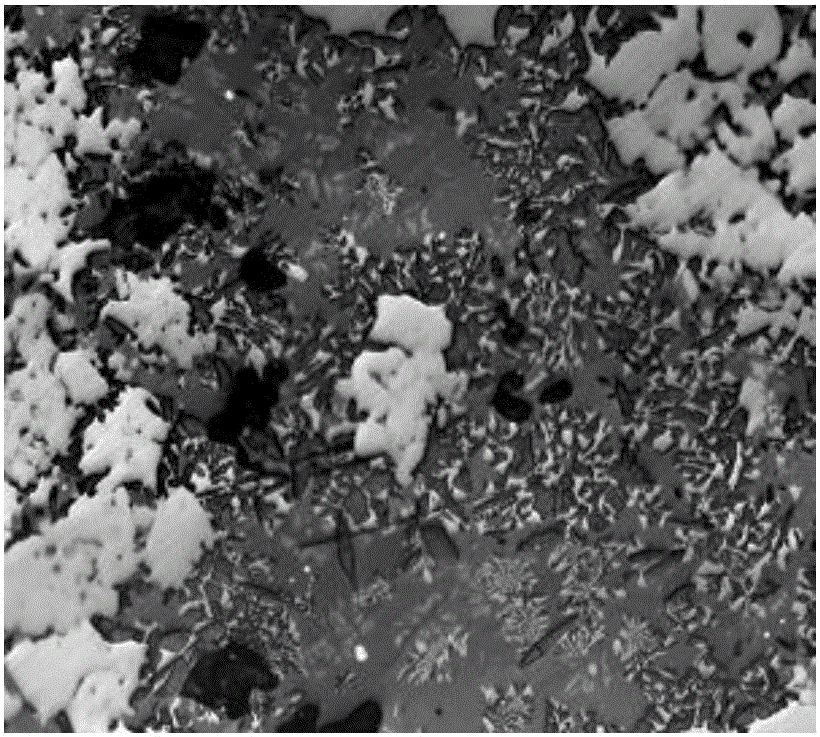

[0056] 2) Image collection: Use a low magnification (40×) optical microscope to capture image information with a camera. Fix the sample, choose to start from the upper left corner of the sample to take the first shot, then make 2 unidirectional movements in the X direction, and take a shot after each movement. Then the microscope moves to the first shooting area, performs one unidirectional movement in the Y direction and takes pictures, and then performs two unidirectional movements in the X direction, and takes pictures after each movement. Repeat with a second unidirectional move in the Y direction and shoot, then ...

Embodiment 2

[0062] 1) Sample preparation and polishing. The sintered ore of WISCO was used in this example, and its chemical composition is shown in Table 2. The sample is roughly ground, hot-mounted, polished, dried, and observed under a microscope.

[0063] Table 1 The chemical composition of the iron-containing charge used in the experiment

[0064] Mineral

[0065]2) Image collection: Use a low magnification (40×) optical microscope to capture image information with a camera. Fix the sample, choose to start from the upper left corner of the sample to take the first shot, then make 2 unidirectional movements in the X direction, and take a shot after each movement. Then the microscope moves to the first shooting area, performs one unidirectional movement in the Y direction and takes pictures, and then performs two unidirectional movements in the X direction, and takes pictures after each movement. Repeat with a second unidirectional move in the Y direction and shoot, then 2...

Embodiment 3

[0071] 1) Sample preparation and polishing. The sintered ore of WISCO was used in this example, and its chemical composition is shown in Table 3. The sample is roughly ground, hot-mounted, polished, dried, and observed under a microscope.

[0072] Table 1 The chemical composition of the iron-containing charge used in the experiment

[0073] Mineral

[0074] 2) Image collection: Use a low magnification (40×) optical microscope to capture image information with a camera. Fix the sample, choose to start from the upper left corner of the sample to take the first shot, then make 2 unidirectional movements in the X direction, and take a shot after each movement. Then the microscope moves to the first shooting area, performs one unidirectional movement in the Y direction and takes pictures, and then performs two unidirectional movements in the X direction, and takes pictures after each movement. Repeat with a second unidirectional move in the Y direction and shoot, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com