A Piston Mechanical Fatigue Test Device That Can Apply Lateral Force

A technology of mechanical fatigue and test device, which is used in the testing of mechanical parts, measuring devices, and testing of machine/structural parts, etc. It can solve the problem of mechanical fatigue results of piston parts, fail to simulate the pressure on the side of the piston, and cannot simulate the lateral direction of the piston. force and other problems, to achieve the effect of simple structure, reasonable device design and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0024] The present invention will be described in detail below with reference to the accompanying drawings and examples.

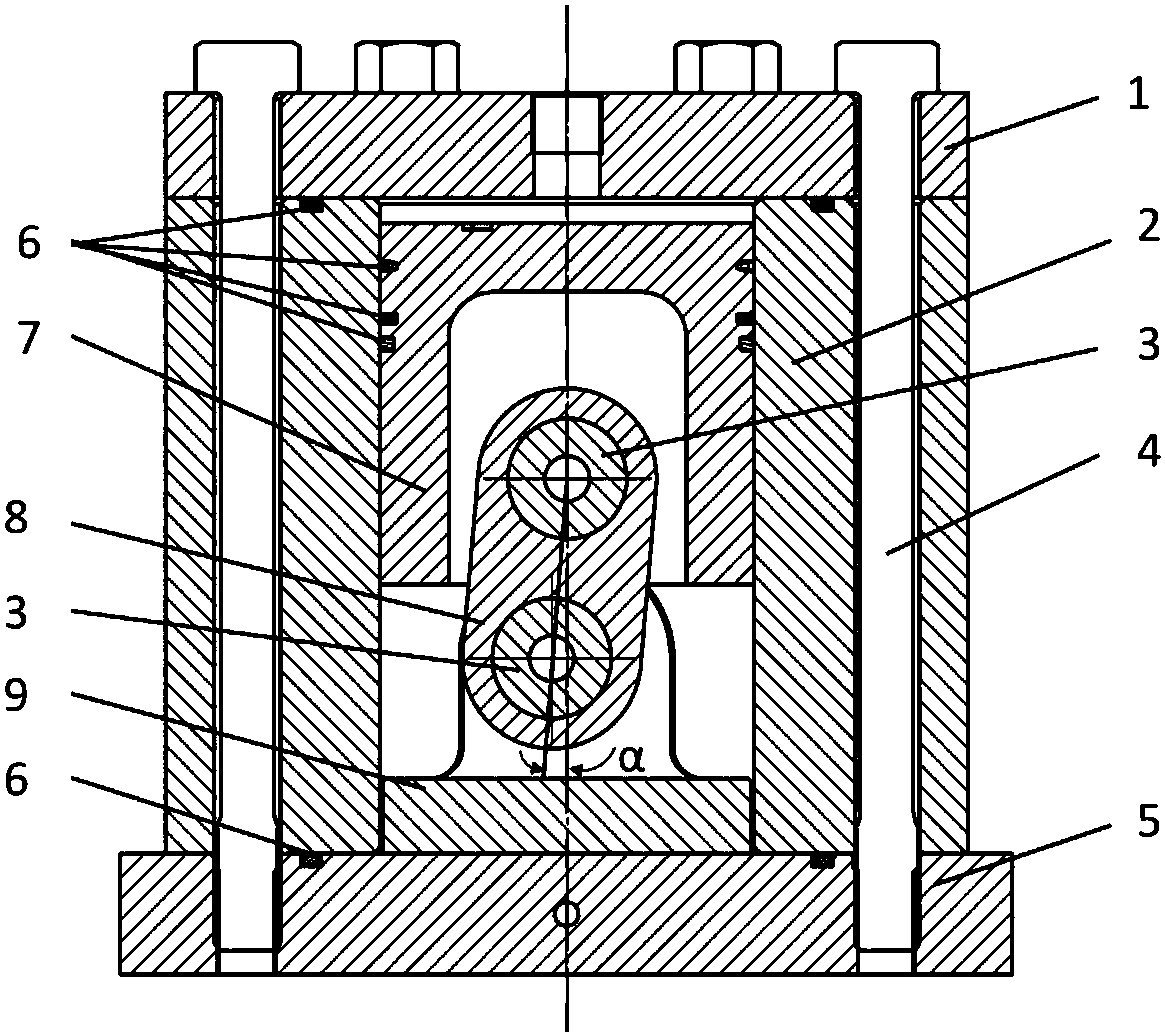

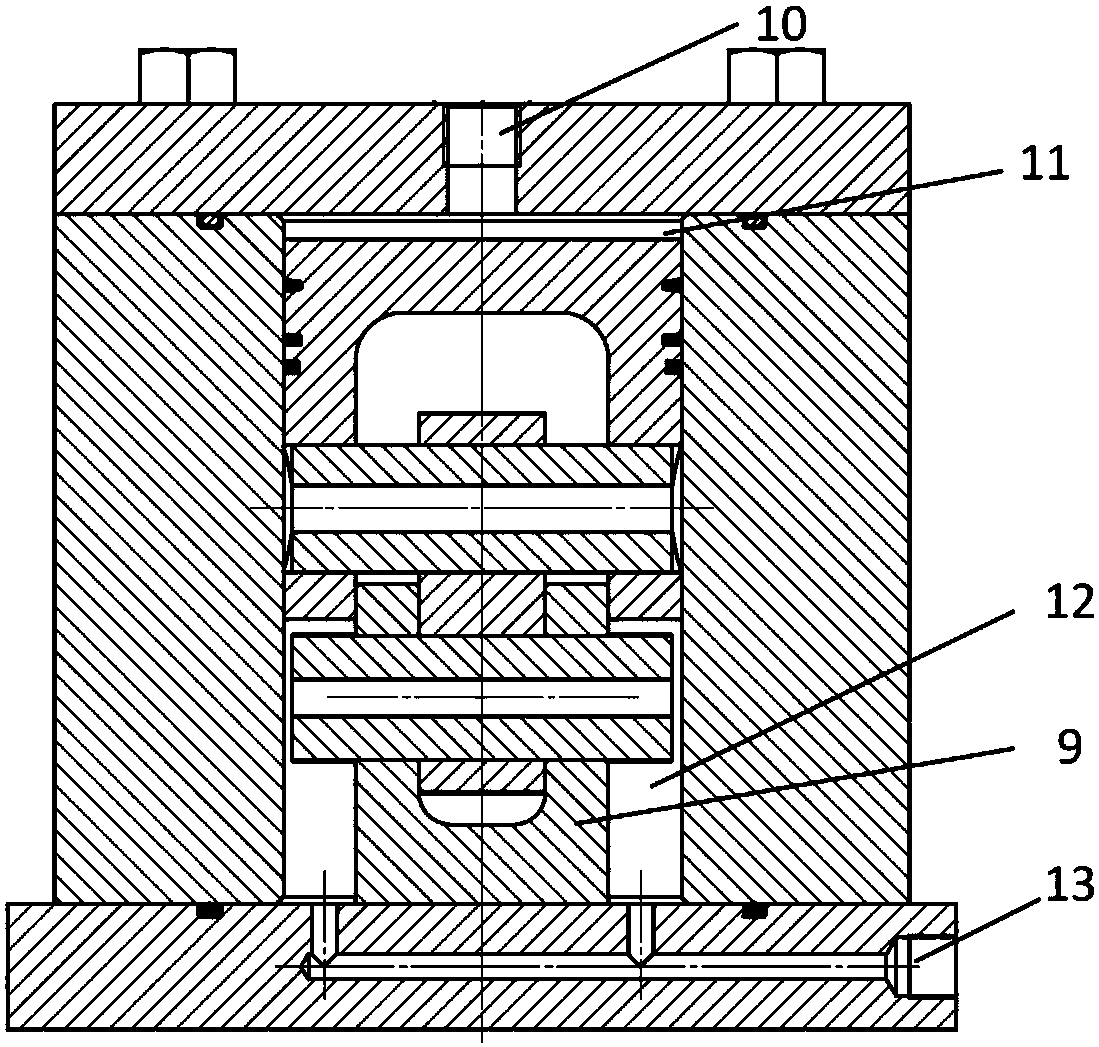

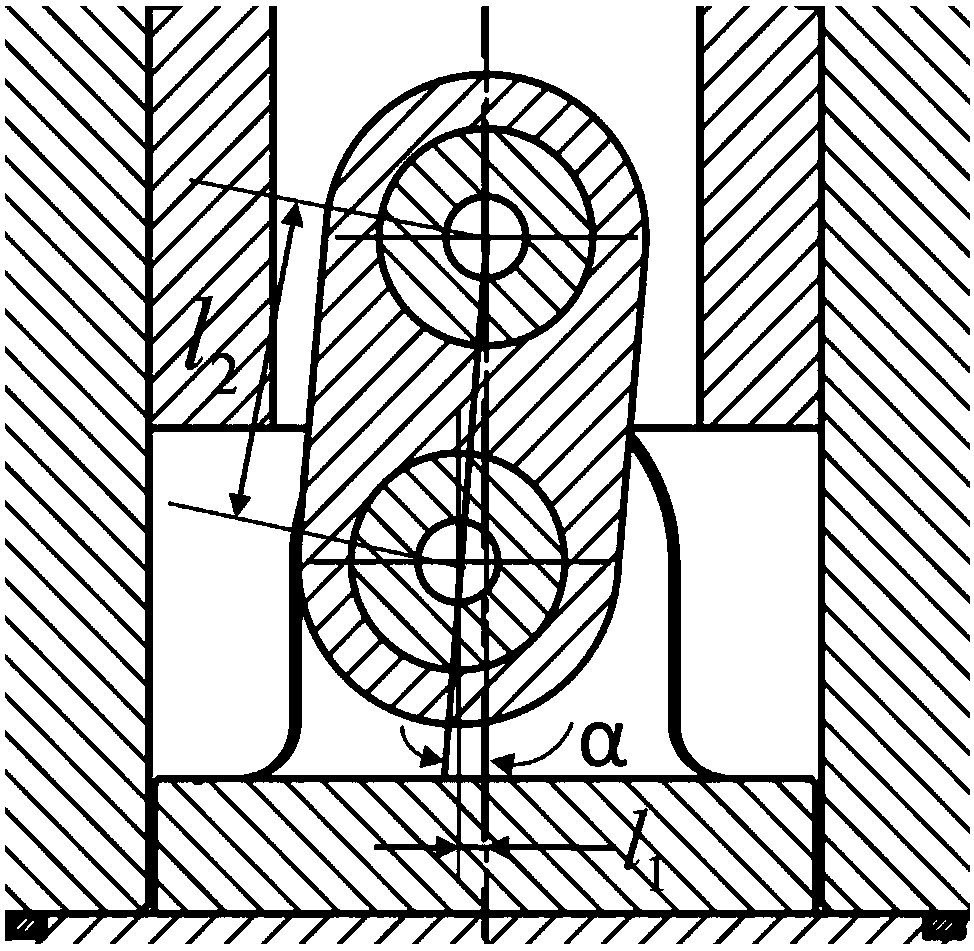

[0025] A piston mechanical fatigue test device capable of applying lateral force, such as figure 1 , 2 As shown, it includes a top plate 1, a support body 2, a piston pin 3, a bolt 4, a base 5, a sealing ring 6, a non-standard connecting rod 8 and a connecting rod base 9, and the top plate 1 and the base 5 are installed on the support body 2 respectively. The upper and lower ends are fixed by bolts 4; the connecting rod base 9 is arranged on the upper surface of the inner base 5 of the support body 2, and one end of the non-standard connecting rod 8 and the pin hole on the connecting rod base 9 adopt the original machine piston The piston pin 3 with the same pin is hingedly connected, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com