System for improving zero bias performance of normal pressure packaged silicon micro-gyroscope

A silicon micro-gyroscope and zero-bias technology, which is applied in steering sensing equipment and other directions, can solve problems such as the trouble of extracting the vibration amplitude of the detection direction, the influence of zero-bias performance, and the fact that the quality factor cannot tend to 0, so as to achieve low power consumption and improve zero. Partial performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

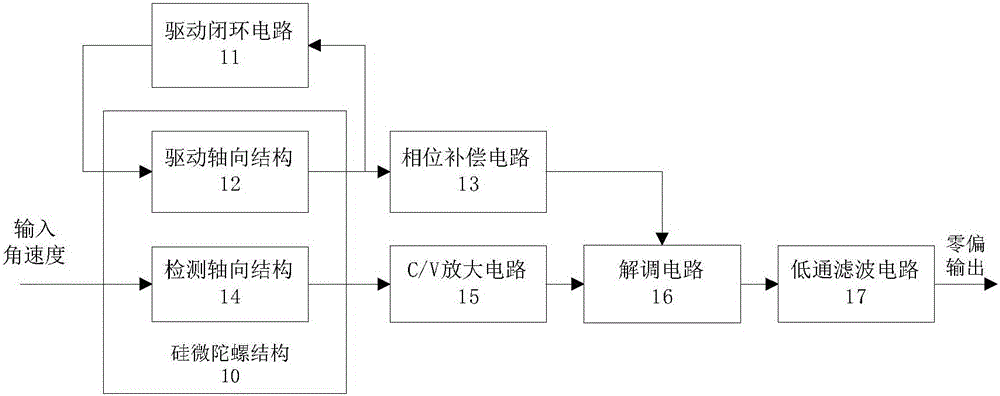

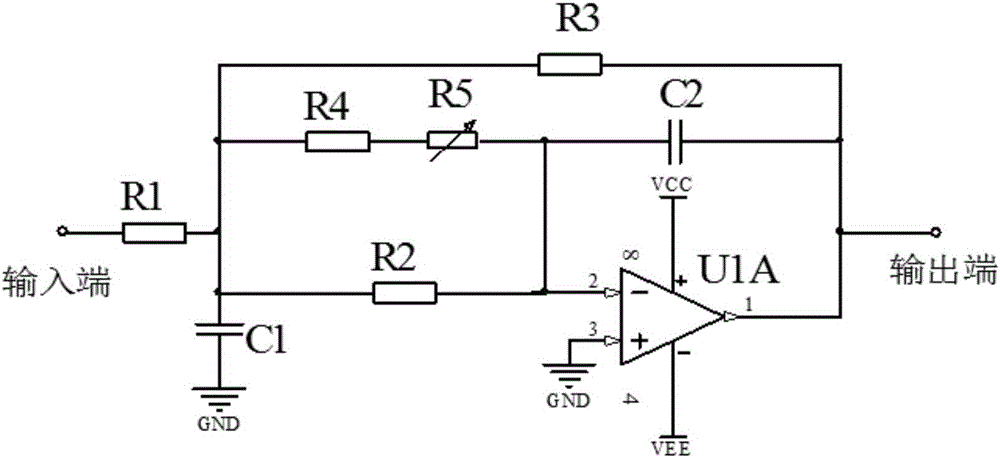

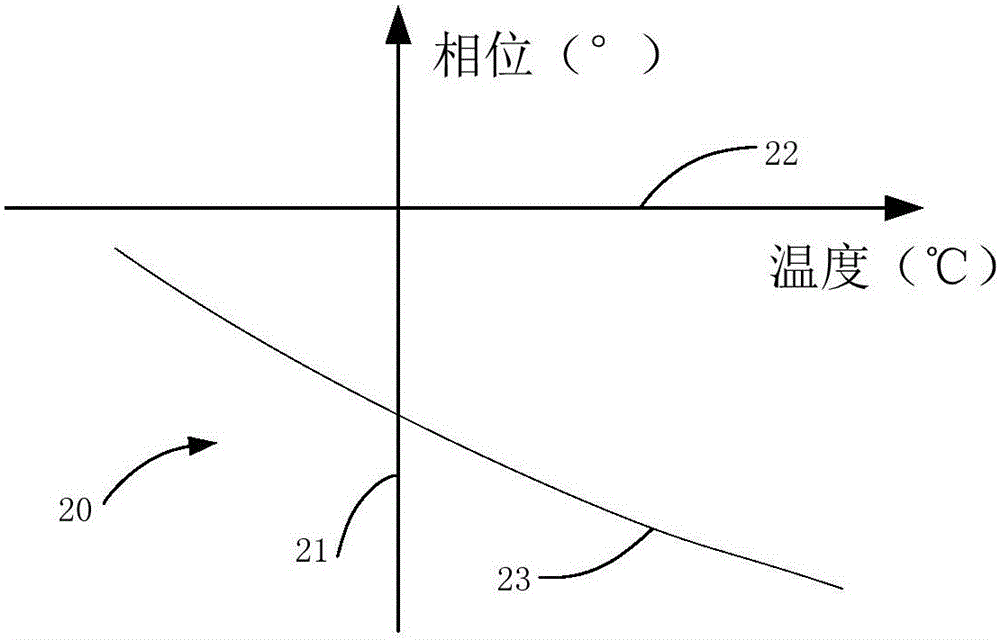

[0035] see figure 1 , the present invention provides a schematic diagram of an open-loop detection circuit of an atmospheric pressure packaged gyroscope. The atmospheric pressure packaged silicon microgyro structure 10 includes a driving axial structure 12 and a detecting axial structure 14. The driving axial structure 12 Form the driving closed-loop circuit with the driving closed-loop circuit 11, ensure that the equivalent mass of the driving mode vibrates along the X-axis direction with constant amplitude and constant frequency; the open-loop detection circuit includes a C / V amplifier circuit 15, a phase compensation circuit 13, demodulation circuit 16 and low pass filter 17. The C / V amplifying circuit 15 is used to convert the capacitance change amount of the detection mode into a voltage signal and amplify it. The phase compensation circuit 13 is used to compensate Q y The additional phase generated by the value becomes smaller, so that the signal to be demodulated and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com