Altitude valve-based air bag control device for ship

A technology of control devices and height valves, which is applied in the direction of gas shock absorbers, springs, shock absorbers, etc., can solve the problems of low control precision, cumbersome operation, complex system, etc., and achieve the effect of simplifying the composition of control devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

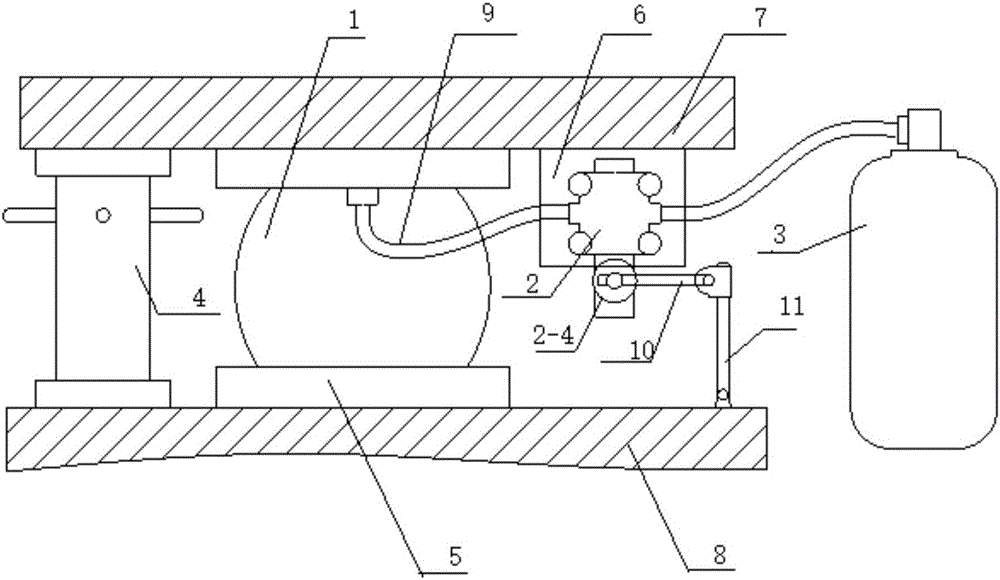

[0012] Referring to the accompanying drawings, the airbag control device for ships based on the altitude valve includes: a shock-absorbing airbag 1, an altitude valve 2, a high-pressure gas cylinder 3 and a support mechanism 4;

[0013] The upper and lower ends of the shock-isolation airbag 3 are installed between the equipment foot 7 and the bottom plate 8 to be isolated through the base 5; the height of the support mechanism 4 is adjustable, and it is also installed between the equipment foot 7 and the bottom plate 8 ;

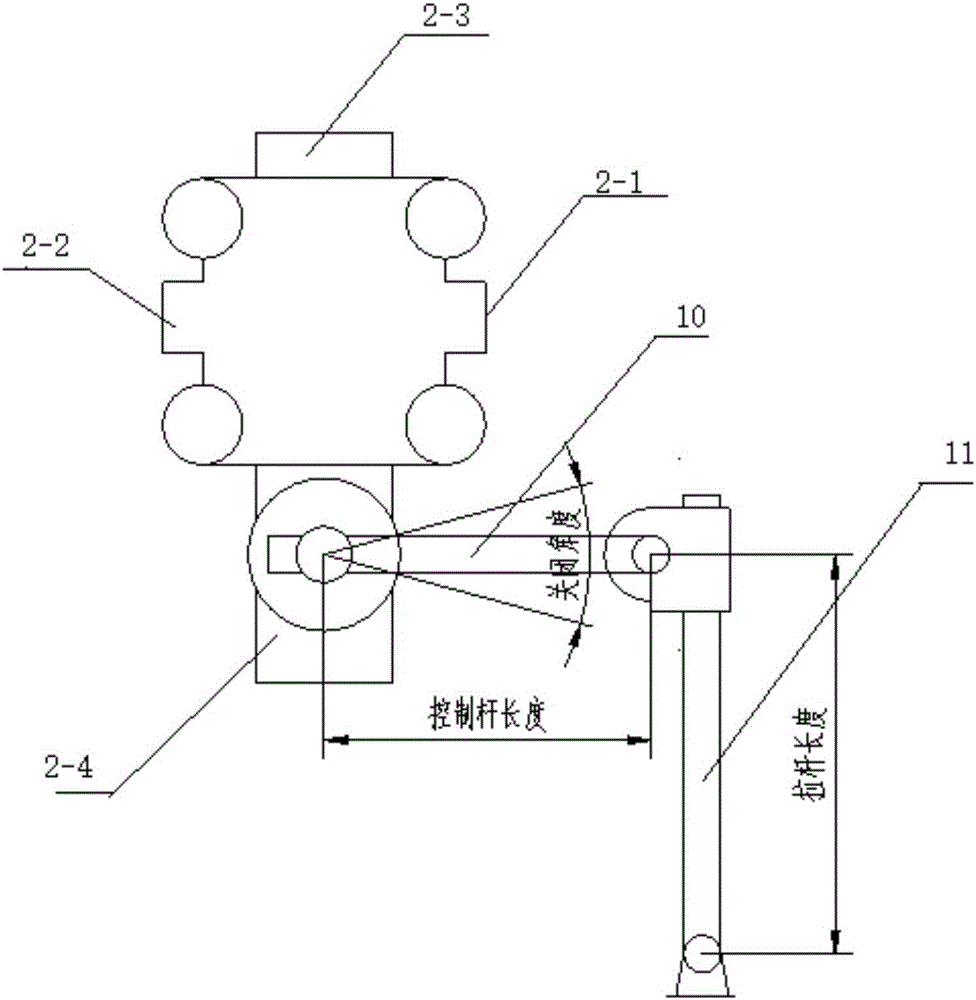

[0014] The height valve 2 is installed on the equipment foot 7 through the mounting plate 6, its air inlet 2-1 communicates with the high-pressure gas cylinder 3, its airbag interface 2-2 communicates with the shock-absorbing airbag 3 through the connecting hose 9, and its exhaust Port 2-3 communicates with the atmosphere, and its main shaft 2-4 is hinged with one end of control rod 10; the other end of control rod 10 is movably connected with pull rod 11 hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com