Looseness-prevention connecting structure with controllable pretightening force of engine cylinder head cover

A technology of engine cylinder head cover and connecting structure, which is applied in the direction of connecting components, engine components, machines/engines, etc., can solve the problems of cylinder head cover bolts being easily crushed, etc., and achieves simple structure, low cost, and enhanced fastening effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

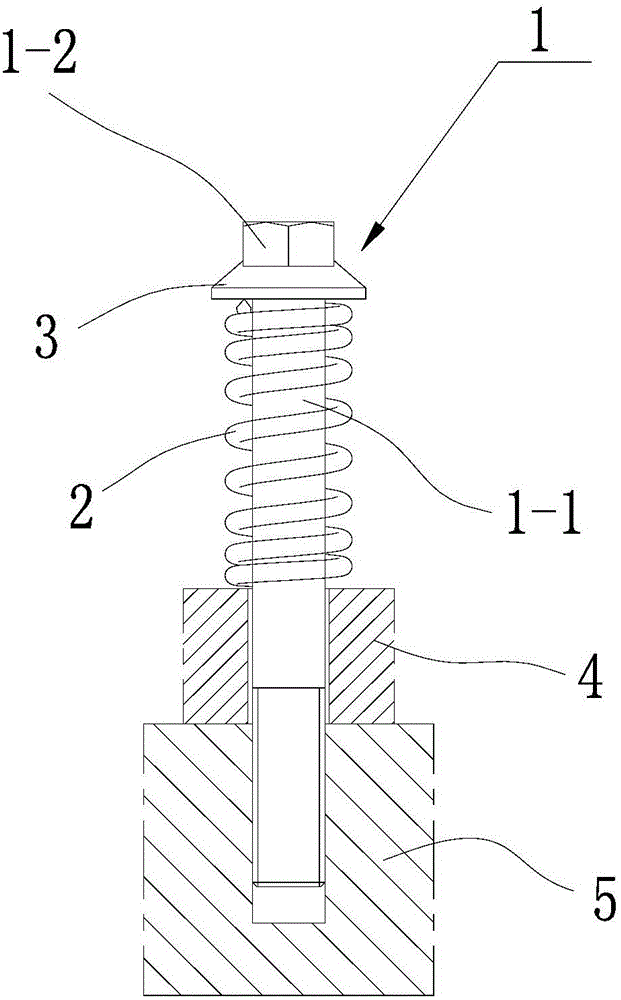

[0011] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0012] see figure 1 , an anti-loose connection structure with controllable pretightening force of an engine cylinder head cover, comprising an engine and a cylinder head cover and a bolt assembly connecting the engine and the cylinder head cover, the bolt assembly includes a bolt 1, a spring 2, and the bolt includes Screw body 1-1, the upper end of the screw body is provided with a nut 1-2, and the bottom of the nut is integrally provided with a pressure cap 3; the spring 2 is set on the screw body, and the lower end of the screw body 1-1 wears The cylinder head cover 4 is threadedly connected with the engine 5, and the spring is in contact with the upper surface of the cylinder head cover.

[0013] In order to improve the assembly efficienc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com