Shuttle valve with middle position unloading function and braking system for hydraulic motor drive

A hydraulic motor and brake system technology, applied in the direction of servo motors, servo motor components, fluid pressure actuators, etc., can solve the problems of brake failure and high oil return back pressure in the hydraulic system, so as to overcome the failure of normal braking movement, to ensure normal operation, and to ensure the effect of accurate reset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

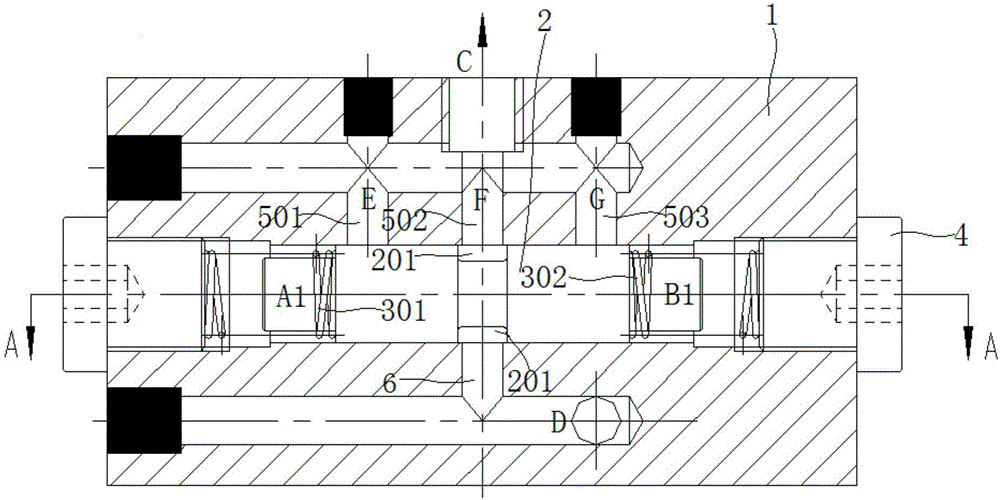

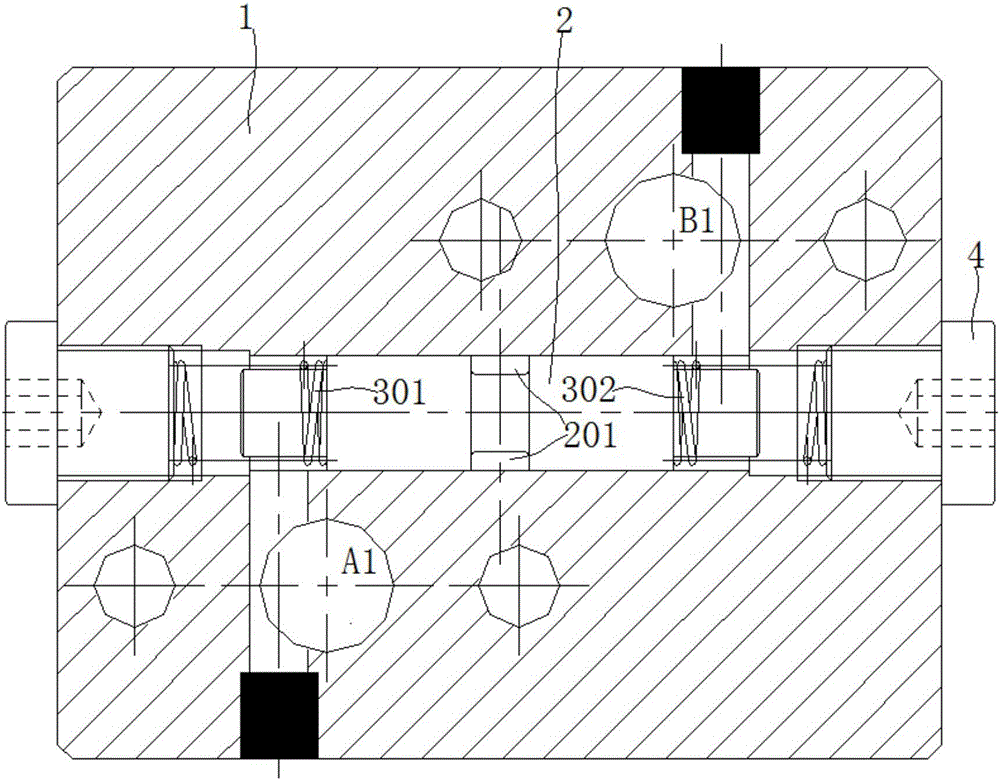

[0033] Such as figure 1 , figure 2 As shown, a shuttle valve with a neutral unloading function in this embodiment includes a valve body 1 and a valve core 2. The valve body 1 is provided with a valve cavity inside, and the valve core 2 is located inside the valve cavity and can move along the valve body. The cavity moves left and right; the left and right ends of the valve cavity communicate with the first oil inlet A1 and the second oil inlet B1 respectively through the oil inlet, the above oil inlet is vertically arranged with the valve cavity, and the valve cavity The top of the tank is connected with the oil outlet C through the oil outlet, and the oil outlet C is connected with the brake acting on the hydraulic motor through the pipeline. In this embodiment, the bottom of the valve cavity is provided with an oil return passage 6, and the middle part of the valve core 2 is processed with a stepped groove 201 (that is, the valve core 2 is processed into a stepped cylindri...

Embodiment 2

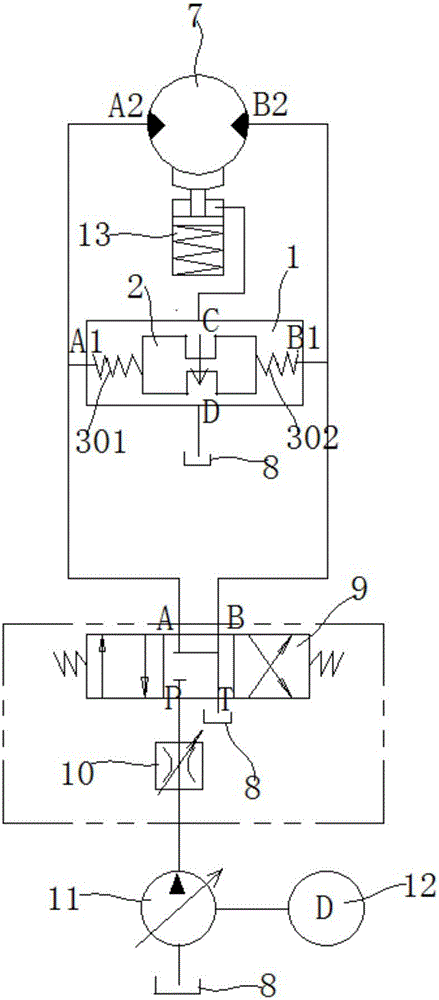

[0036] Such as Figure 1-3 As shown, a shuttle valve with a neutral unloading function in this embodiment includes a valve body 1 and a valve core 2. The valve body 1 is provided with a valve cavity inside, and the valve core 2 is located inside the valve cavity and can move along the valve body. The cavity moves left and right; the left and right ends of the valve cavity communicate with the first oil inlet A1 and the second oil inlet B1 respectively through the oil inlet, and the above oil inlet and the valve cavity are vertically arranged, so that on the one hand it can Oil can be fed into the valve chamber of the shuttle valve through the first oil inlet A1 and the second oil inlet B1; Oil ports A2 and B2 enter oil. The top of the valve cavity communicates with the oil outlet C through the oil outlet, and the oil outlet C is connected with the brake acting on the hydraulic motor through the pipeline. In this embodiment, the bottom of the valve cavity is provided with an ...

Embodiment 3

[0045] A rotary drive system of a log grab in this embodiment includes a hydraulic motor 7 and a gear transmission mechanism, and the hydraulic motor 7 drives the gear transmission mechanism to rotate, thereby driving the grab bucket to rotate. The rotary drive system of this embodiment also includes the embodiment 2 hydraulic motor braking system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com