Helicon wave plasma induction thruster

A plasma and helical wave technology, applied in the field of space exploration, can solve the problems such as the inability to match the power of the spaceborne power supply, the high IPPT electric power, and the limited working life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

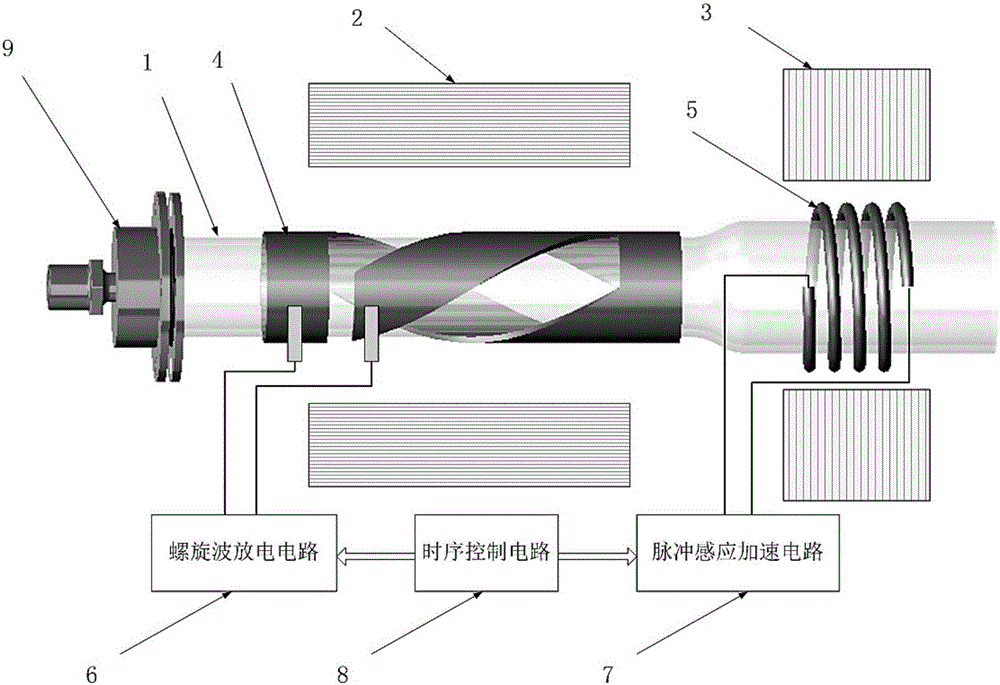

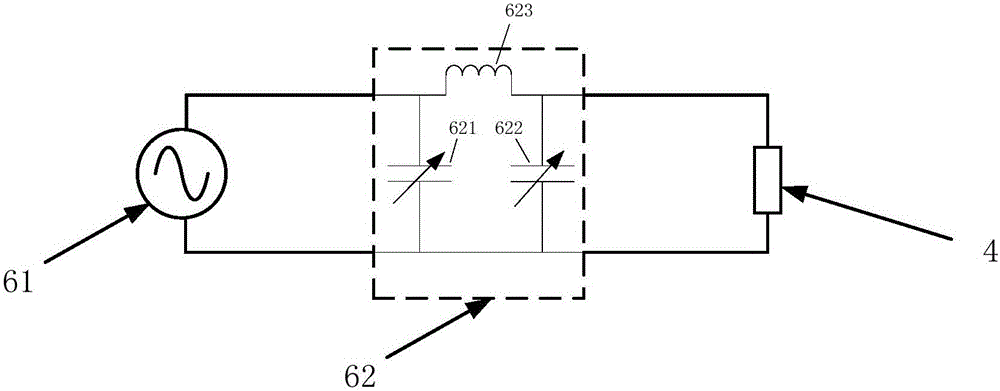

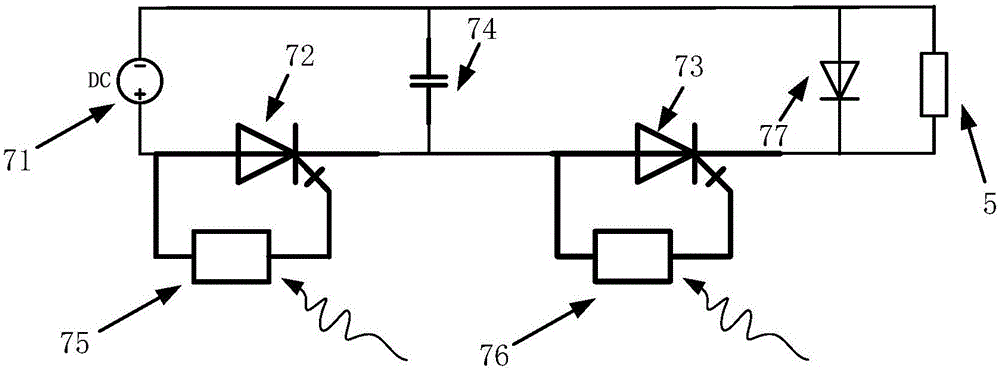

[0049] refer to figure 1 , the preferred embodiment of the present invention provides a helicon wave plasma induction thruster, including a discharge chamber 1 for forming a helicon wave plasma in its inner cavity, and the outside of the discharge chamber 1 is sequentially arranged for the discharge chamber 1 The first magnet 2 forming the axial magnetic field inside, the second magnet 3 used to form the radial magnetic field in the discharge chamber 1; The helicon wave discharge antenna 4 for generating helicon wave plasma with medium ionization, and the inductive accelerator coil 5 for accelerating the helicon wave plasma in a radial magnetic field; the helicon wave plasma inductive thruster...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com