Novel hydraulic oscillator with energy gathering and damping functions

A hydraulic oscillator, a new type of technology, applied in the field of new hydraulic oscillators and new downhole drilling tools, can solve the problems of large friction resistance, prone to downhole accidents, low drilling pressure transmission efficiency, etc., to achieve efficient rock breaking and alleviate stick-slip Phenomenon, the effect of reducing the number of trips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

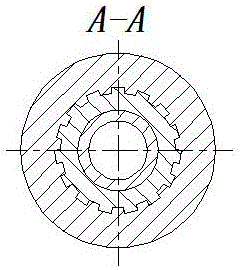

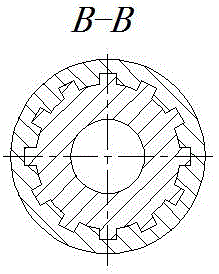

[0014] The present invention will be further described below in conjunction with accompanying drawing:

[0015] see figure 1 , The new type hydraulic oscillator with energy-gathering and shock-absorbing function is composed of three parts: a shock-absorbing assembly, a transmission assembly, and an oscillation assembly. The front end of the transmission assembly is equipped with an oscillation assembly, and the rear end is equipped with a shock-absorbing assembly. The shock absorbing assembly includes an upper body 1, a rectangular sealing ring a2, a rectangular sealing ring b3, a rectangular sealing ring c4, a locking joint 5, an O-shaped sealing ring a6, an upper vibration-absorbing ring 7, an upper locking ring 8, and a central Pipe 9, washer 10, middle vibration-absorbing ring 11, spline joint 12, lower locking ring 13, lower vibration-absorbing ring 14, rectangular sealing ring d15, sealing ring 16, rectangular sealing ring e17, intermediate nipple 18, and the rectangular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com