Construction method of long-span cantilevered special-shaped overrun structural steel corridor

A technology of large-span cantilever and structural steel, which is applied in building structure, processing of building materials, construction, etc., can solve problems such as the inability to complete the construction of steel structure corridors and the inability of floor slabs to carry 425 tons, and achieve Satisfying the construction process, reducing safety and saving working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

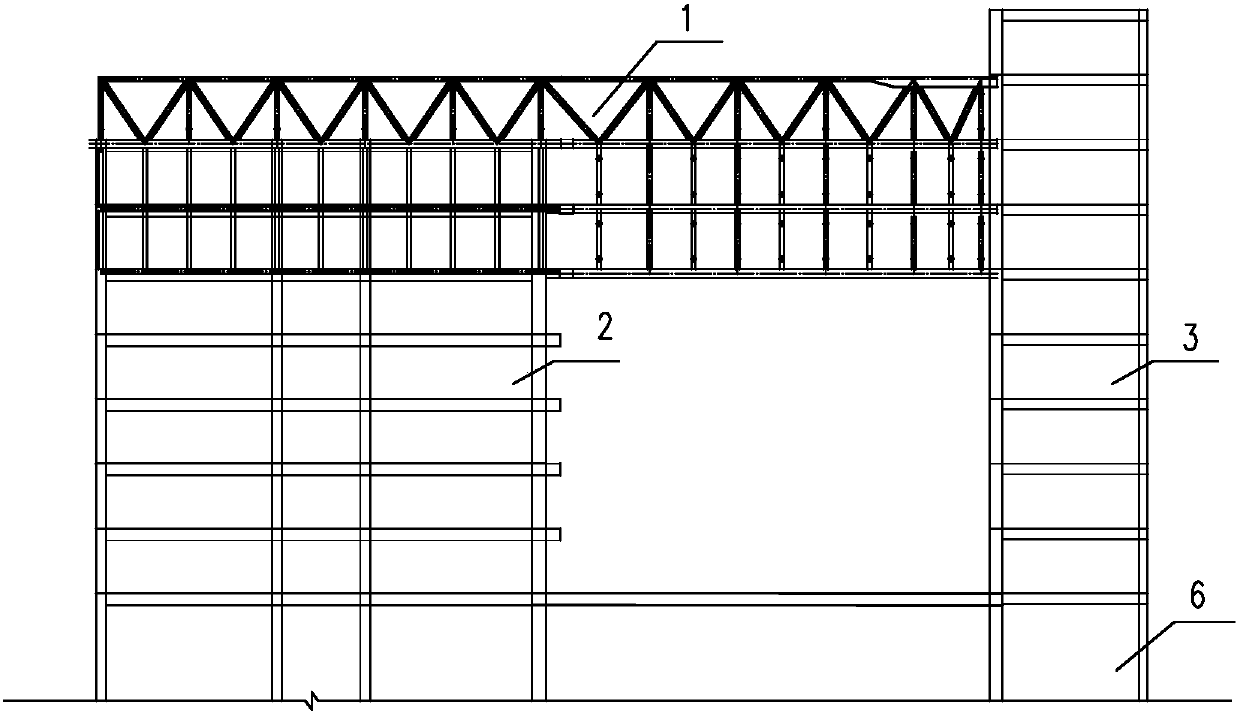

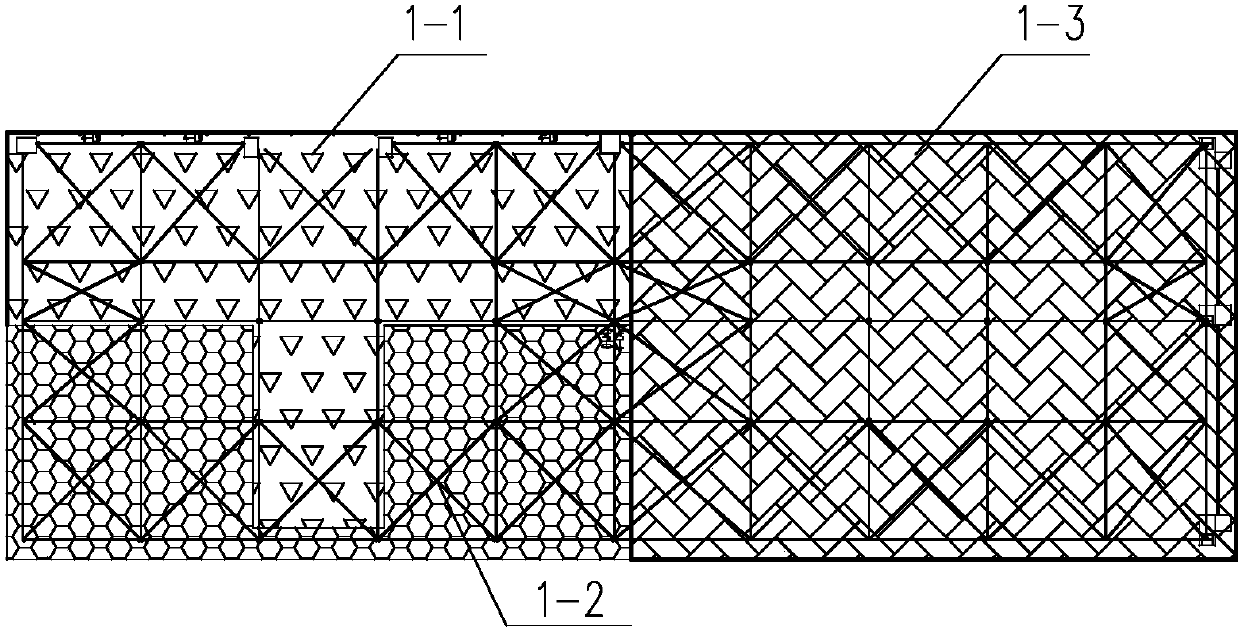

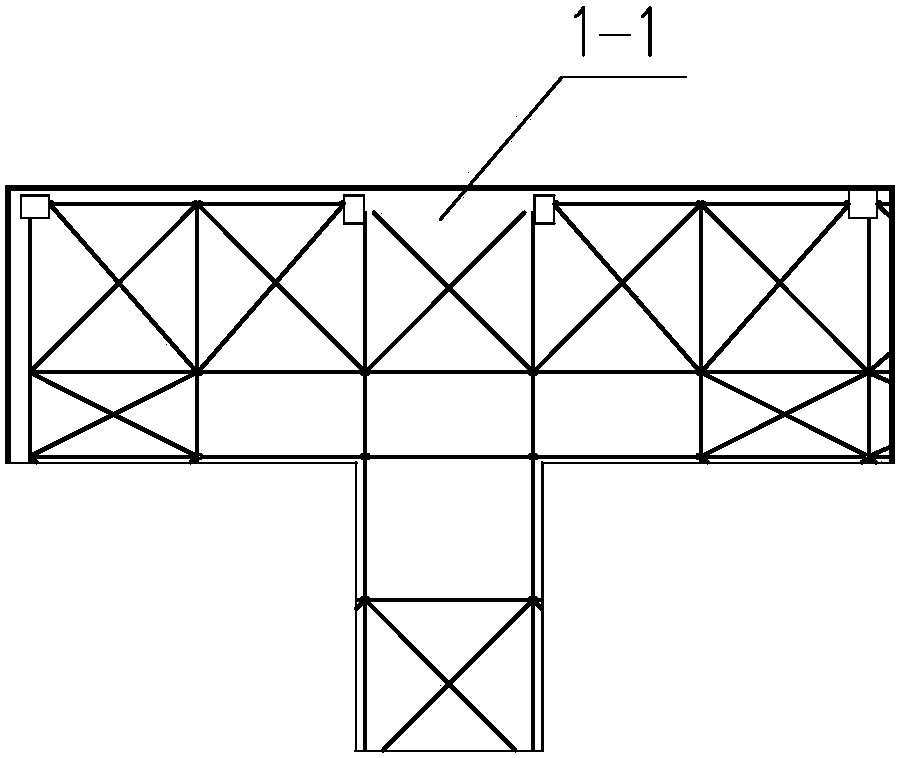

[0060] Please refer to the accompanying drawings, a construction method for a long-span cantilevered special-shaped overrun steel corridor, the steel corridor 1 connects the A tower 2 and the B tower 3, and the upper steel structure and the lower hanging layer are mainly connected by trusses Composed of steel structures, the overall plane of the steel corridor 1 is rectangular, including left and right parts, the left part is connected to Tower A 2, and is suspended from the inner part of the corridor structure on the floor panel of Tower A 2 and the corridor connected to it The right part is the suspended part of the corridor connecting Tower A 2 and Tower B 3 together, and the suspended part of the corridor and the suspended part of the corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com