A kind of asphalt pavement comprehensive maintenance vehicle that can not only fry materials on site but also store materials in heat preservation

A technology for asphalt pavement and maintenance vehicles, which is applied in the direction of roads, roads, and road repairs. The effects of diversified feeding methods and strong climate adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

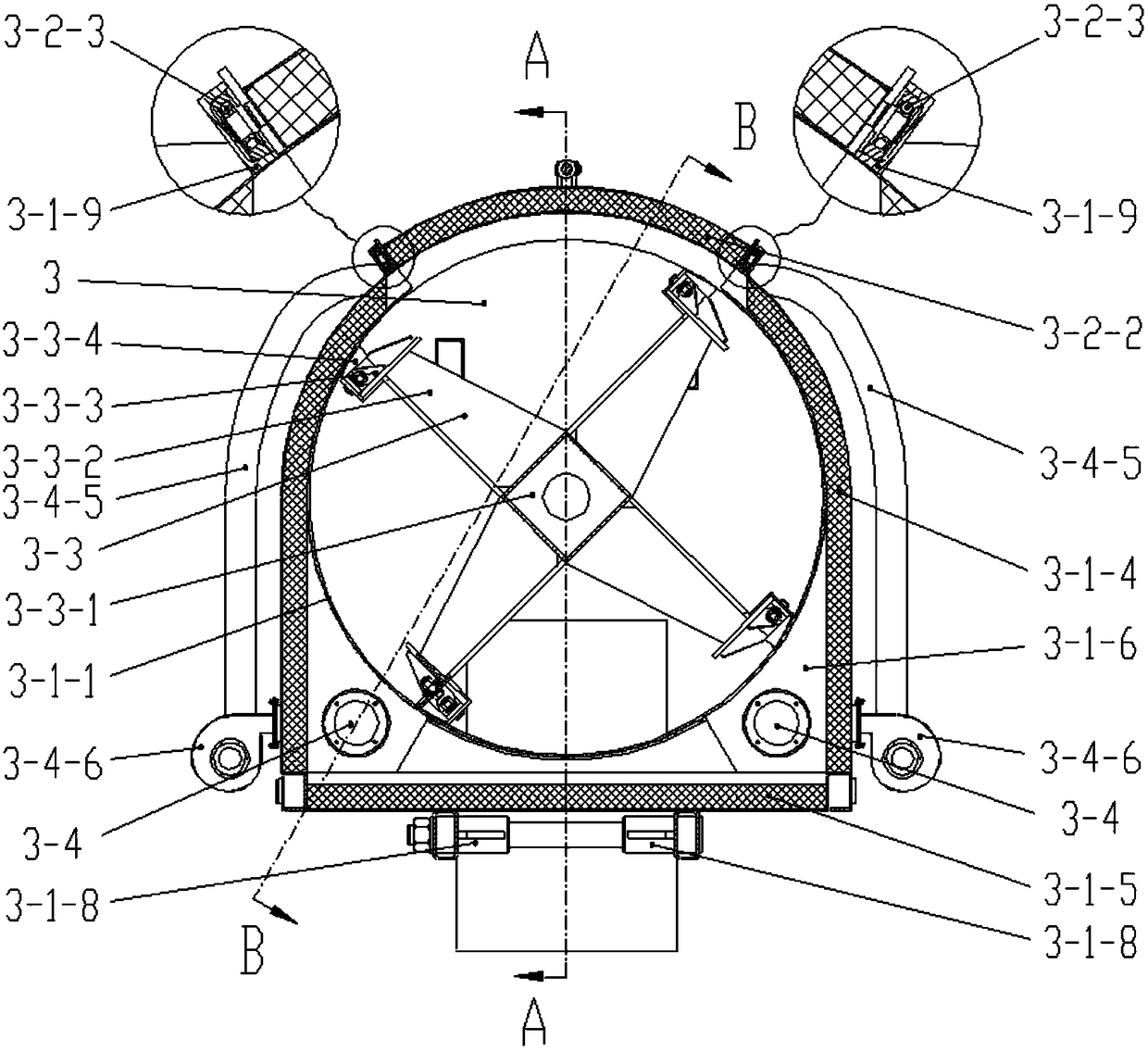

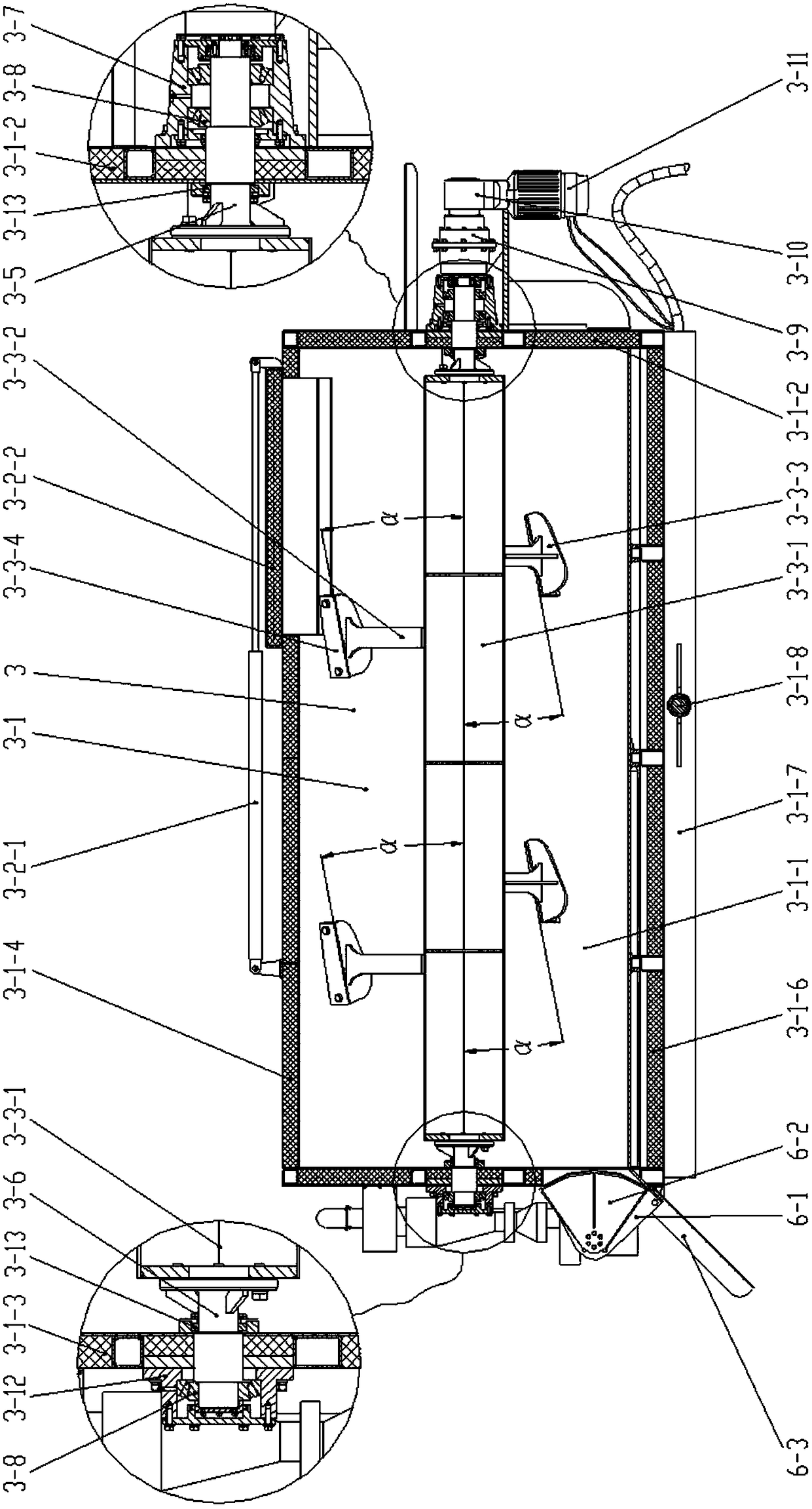

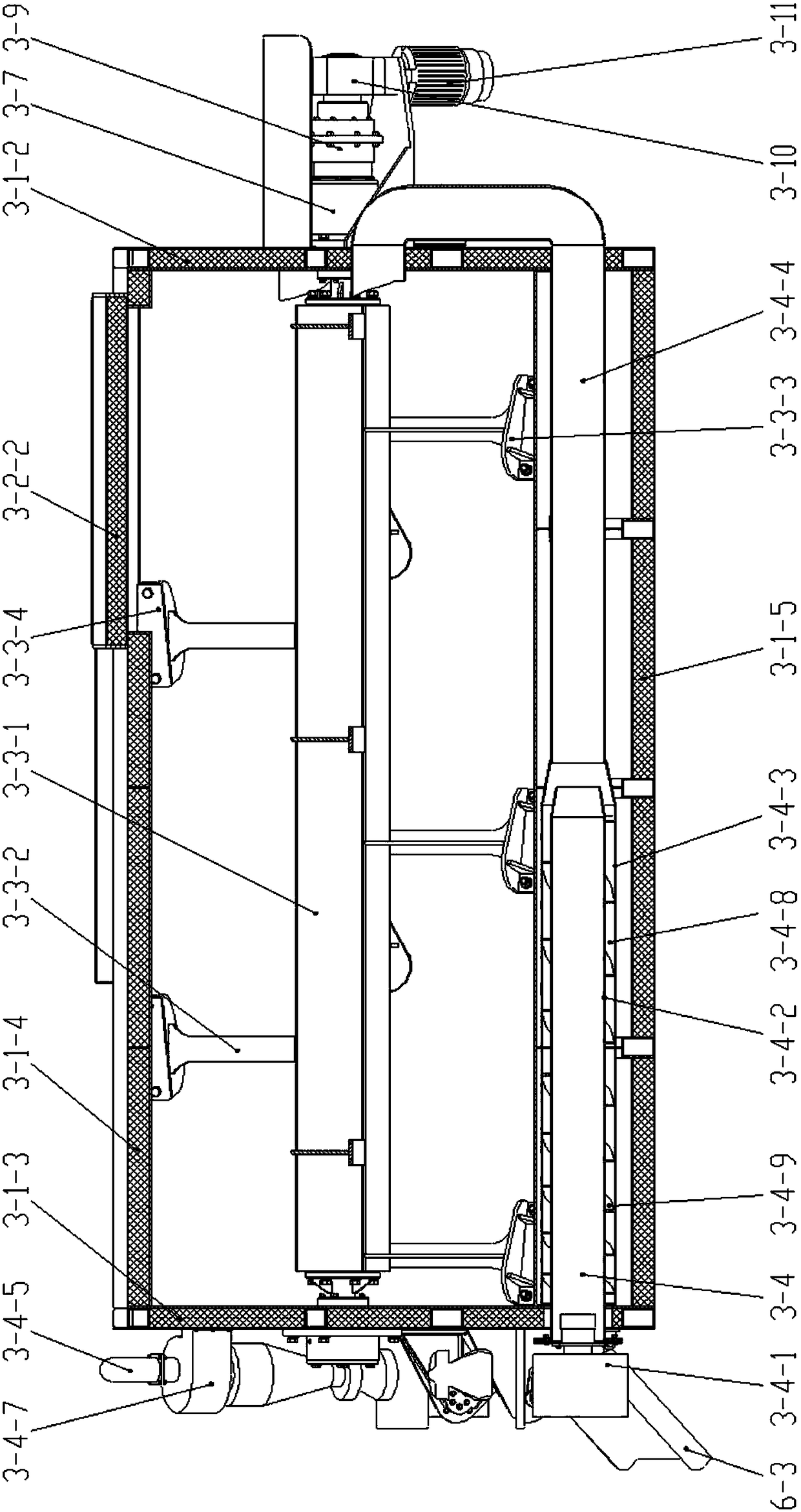

[0036] Such as Figure 1 to Figure 15 As shown, a comprehensive asphalt pavement maintenance vehicle capable of frying materials on site and storing materials in heat preservation according to the present invention includes a vehicle chassis 1, a vehicle frame 2, a hopper system 3, a hopper lifting mechanism 4, and a hydraulic grab top Material system 5, discharge device 6 and power system 7.

[0037] In this embodiment, the tail of the main support beam 1-1 of the automobile chassis 1 is provided with a silo support beam 1-2, and the upper left and right ends of the silo support beam 1-2 are welded with the silo lifting support base 1- 3. The bottom of the silo support beam 1-2 is connected with the rear protection device 1-4 by several bolts, and the silo lifting cylinder base 1-5 is provided at the middle left and right ends of the main support beam 1-1.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com