Hot air non-woven setting machine with paired held net curtain automatic correction function

A technology of hot air non-woven fabric and automatic deviation correction, which is applied in the direction of non-woven fabrics, textiles and papermaking, heating/cooling fabrics, etc. Follow up questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the following descriptions, all concepts related to directionality or orientation of up, down, left, right, front and rear are based on figure 1 The shown position status is a reference, so it cannot be understood as a special limitation on the technical solution provided by the present invention.

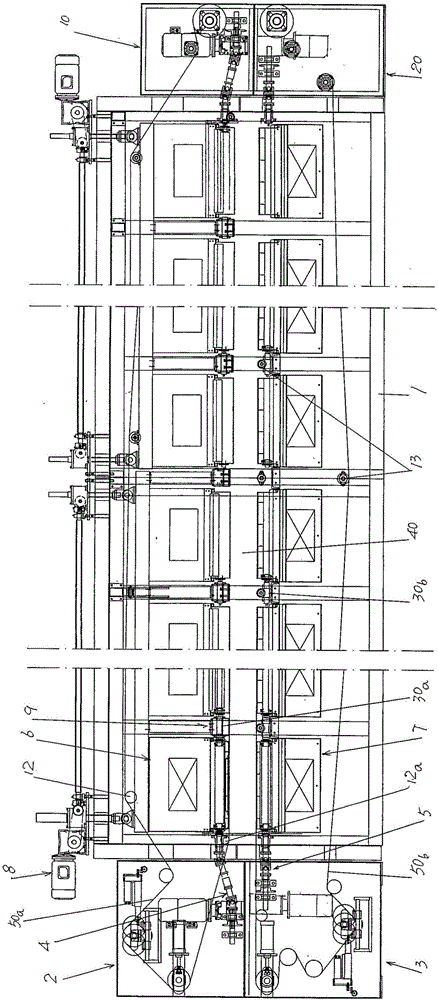

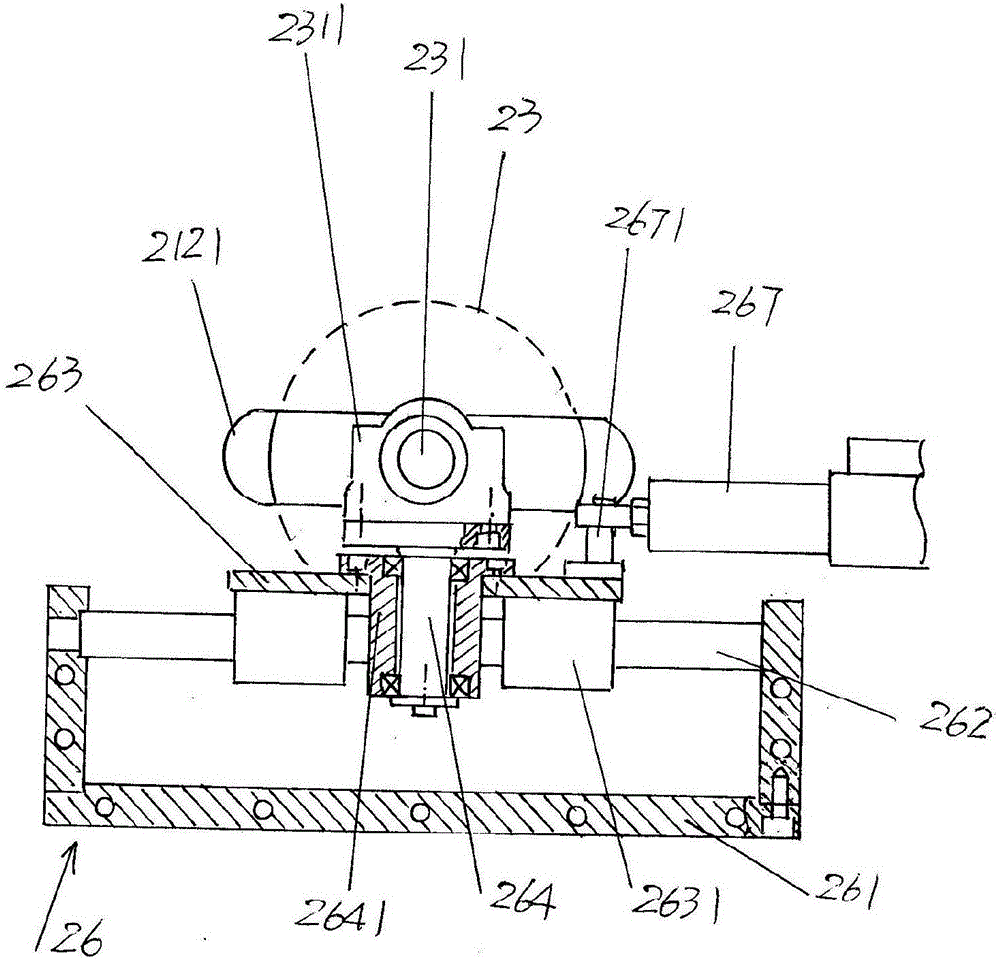

[0032] See figure 1 , shows a frame 1 of frame-like structure, and a high-temperature air generating mechanism 11 is extended on the rear side of the frame 1 in the length direction (see Image 6 with Figure 9 ); have shown a net curtain deviation correction mechanism 2 and a following net curtain deviation correction mechanism 3 as the technical gist of the present invention, the upper left side upper position of the net curtain deviation correction mechanism 2 corresponding to the aforementioned frame 1 and The frame 1 is connected, and the lower mesh curtain deviation correction mechanism 3 corresponds to the bottom of the upper mesh curtain deviation correction mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com