Diamond electroplating equipment and electroplating method thereof

An electroplating equipment, diamond technology, applied in electrolytic coatings, electrolytic processes, electrolytic components, etc., can solve the problems of low product qualification rate, messy equipment layout, large floor space, etc., achieving a high degree of automation, reasonable equipment layout, occupying Small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

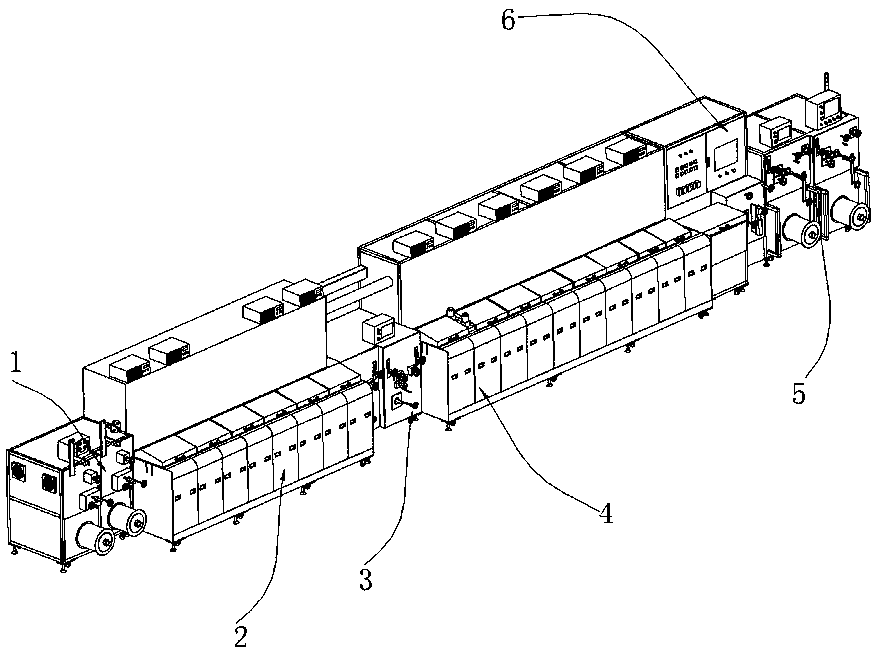

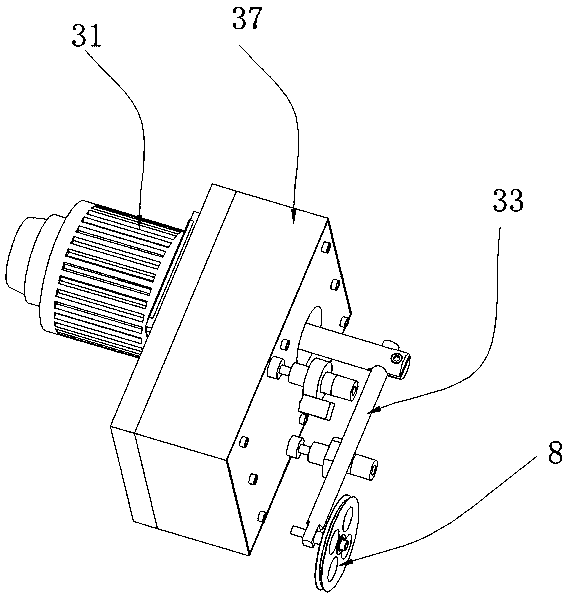

[0074] see figure 1 , The diamond electroplating equipment provided by the present invention includes a servo pay-off device 1, an electrolytic degreasing device 2, a constant tension adjustment device 3, a sand blowing and stirring device 4, a wire winding device 5 and a total control system 6; the servo pay-off device 1. The electrolytic degreasing device 2, the sand blowing stirring device 4 and the cable take-up device 5 are connected in sequence, and the servo unwinding device 1, the electrolytic degreasing device 2, the sand blowing stirring device 4 and the cable take-up device 5 are all connected with each other. The constant tension adjustment device 3 is connected, and the constant tension adjustment device 3 controls the 7 tension of the wire to be consistent; and the servo pay-off device 1, the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com