Forward osmosis membrane and MF (microfiltration) membrane coupling anaerobic sewage treatment method

A technology of forward osmosis membrane and microfiltration membrane, which is applied in the field of sewage treatment, can solve problems such as limiting the application of reactors, and achieve the effect of recycling resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: anaerobic reactor coupling forward osmosis membrane and microfiltration membrane

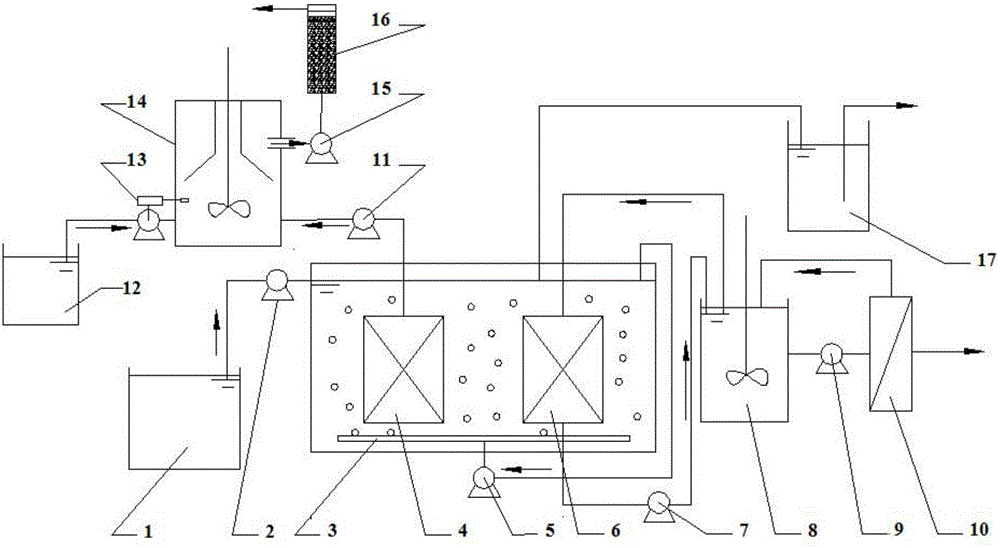

[0038] figure 1 It is a structural schematic diagram of an anaerobic reactor (MFO-AnMBR) coupled with a forward osmosis membrane and a microfiltration membrane of the present invention.

[0039]The anaerobic reactor mainly includes a membrane reaction device, a draw liquid pool 8, a RO membrane treatment device 10, a sedimentation tank 14, and an adsorption device 16; the membrane reaction device includes a MF membrane module 4 and a FO membrane module 6; the MF The membrane module 4 is connected with the sedimentation tank 14 through the pipeline, and the sedimentation tank 14 is connected with the adsorption device 16 through the pipeline; the FO membrane module 6 is connected with the draw liquid pool 8 through the pipeline, and the draw liquid pool 8 is connected with the RO membrane treatment device 10 connect.

Embodiment 2

[0049] Embodiment 2: utilize MFO-AnMBR of the present invention to carry out sewage treatment

[0050] use as figure 1 A novel anaerobic reactor (MFO-AnMBR) coupled with forward osmosis membrane and microfiltration membrane with the structure shown, operates at room temperature.

[0051] The artificially prepared simulated urban sewage is introduced, and its water quality index is: TOC: 143.97±2.23mg / L, NH 4 -N: 28.95±2.34mg / L, TN: 30.71±2.18mg / L, TP: 2.70±0.34mg / L. FO and MF flat membrane modules are used for membrane modules, which are made of triacetate fiber (CTA) and polyvinylidene fluoride (PVDF) respectively, and the membrane area is 0.025m 2 , where the average pore size of MF is 0.2 μm. The water inlet pump 2 pumps the water from the water inlet tank 1 into the MFO-AnMBR, and is rapidly mixed under the action of the biogas circulation pump 5 . A part of the mixed liquid passes through the FO membrane module 6 under the action of the drawing liquid 8 to realize the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com