A kind of preparation method of bamboo pulp cellulose & poly n-vinyl formamide composite flocculation decolorization material

A technology of vinylformamide and cellulose, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve unseen problems, achieve low prices, reduce production costs, and achieve significant decolorization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

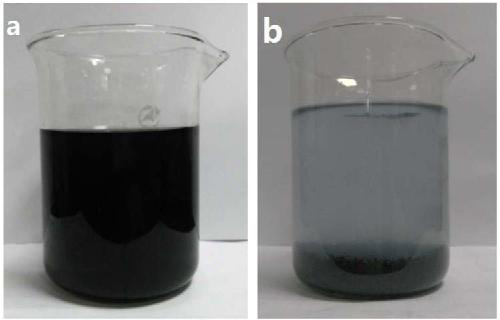

Image

Examples

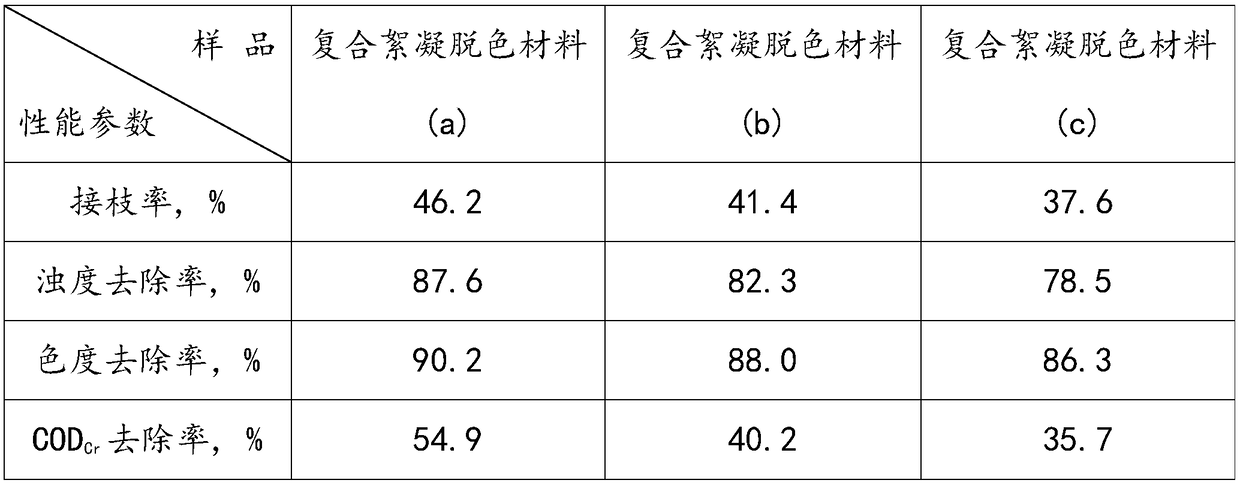

Embodiment 1

[0021] 1) Cutting the white bamboo pulp board, washing it with water, drying, crushing, and filtering through a 200-mesh sieve to obtain white bamboo cellulose with a particle size of 0.07 mm;

[0022] 2) Weigh the cellulose obtained in step 1), dissolve it in a mixed solution containing 7% NaOH and 13% urea, seal it and place it in a -25°C environment and freeze it for 1.5 hours, wherein the cellulose The mass ratio with sodium hydroxide is 1:1.5, and the mass ratio of cellulose and urea is 1:3.5 to obtain a colorless, transparent cellulose solution;

[0023] 3) Nitrogen gas was passed through the cellulose solution obtained in step 2) for 30 minutes, and the initiator ammonium persulfate was added. The mass ratio of cellulose and ammonium persulfate was 1:0.25, and the reaction was carried out for 15 minutes to obtain the initiated cellulose solution. Phyllostachys cellulose solution;

[0024] 4) Add grafting monomer poly-N-vinyl formamide to the induced cellulose solution ...

Embodiment 2

[0027] 1) cutting, washing, drying and crushing the Cizhu pulp board, and filtering through a 150-mesh sieve to obtain Cizhu cellulose with a particle size of 0.1 mm;

[0028] 2) Weigh the Cizhu cellulose obtained in step 1), dissolve it in a mixed solution containing 6% NaOH and 15% urea, seal it and place it in a -20°C environment and freeze it for 2 hours, wherein the Cizhu cellulose is oxidized with hydrogen The mass ratio of sodium is 1:2, the mass ratio of Cizhu cellulose to urea is 1:2.5, and a colorless, transparent Cizhu cellulose solution is obtained;

[0029] 3) Pass nitrogen to the Cizhu cellulose solution obtained in step 2) for 35 minutes, add initiator ammonium persulfate, the mass ratio of Cizhu cellulose to ammonium persulfate is 1:0.2, and react for 10 minutes to obtain the initiated Cizhu fiber prime solution;

[0030] 4) Add grafting monomer poly-N-vinyl formamide to step 3) in the initiated Cizhu cellulose solution, wherein the mass ratio of Cizhu cellulo...

Embodiment 3

[0033]1) cutting the green bamboo pulp board, washing it with water, drying, crushing, and filtering through a 100-mesh sieve to obtain green bamboo cellulose with a particle size of 0.14 mm;

[0034] 2) Weigh the green bamboo cellulose obtained in step 1), dissolve it in a mixed solution containing 8% NaOH and 10% urea, seal it and place it in a -30°C environment for freezing for 1 hour, wherein the green bamboo cellulose and The mass ratio of sodium hydroxide is 1:1.8, and the mass ratio of green bamboo cellulose and urea is 1:3, obtains colorless, transparent green bamboo cellulose solution;

[0035] 3) To the green bamboo cellulose solution obtained in step 2), pass nitrogen gas for 40 min, add initiator ammonium persulfate, the mass ratio of green bamboo cellulose to ammonium persulfate is 1:0.3, react for 20 min, and obtain the initiated Green bamboo cellulose solution;

[0036] 4) Add grafting monomer poly-N-vinyl formamide to step 3) in the initiated green bamboo cell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com