Method for preparing graphene nanobelt fibers with 3D solution printing technology

A graphene nanoribbon and solution technology, which is applied in the direction of graphene nanoribbon, graphene, nanotechnology for materials and surface science, etc., can solve the problems of complex process and long production cycle, and achieve simple process and high precision , high flexibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

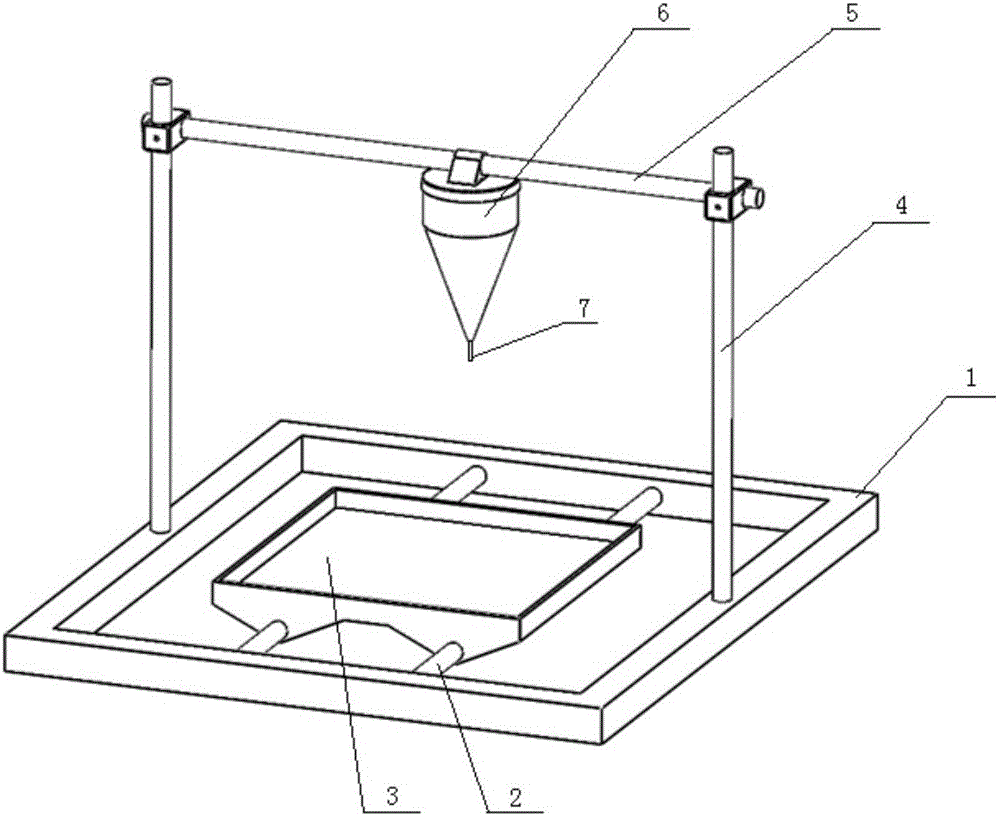

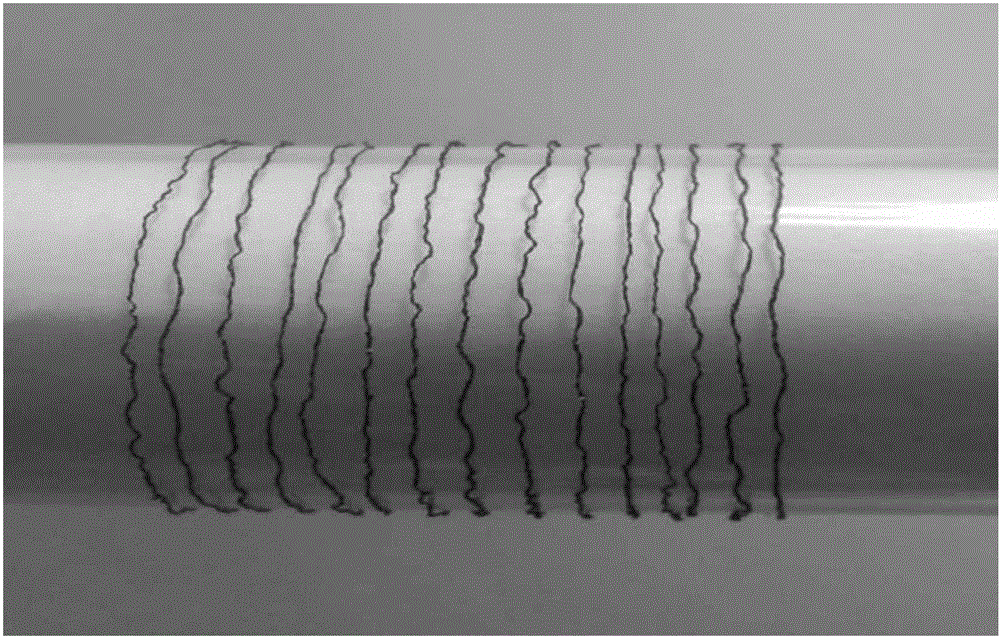

[0016] Specific embodiment one: utilize 3D solution printing technique of the present embodiment to prepare the method for graphene nanoribbon fiber, carry out according to the following steps:

[0017] 1. Put the multi-walled carbon nanotubes into the mixed solution of concentrated sulfuric acid and concentrated phosphoric acid, add potassium permanganate, and react at a temperature of 55-80°C for 1-5 hours. After the reaction, add Dilute the ice solution of hydrogen oxide, then use a high-speed centrifuge to separate the solid from the liquid, and extract the solid; then filter the solid with hydrochloric acid and deionized water until it is neutral, and dry it in vacuum to obtain a graphene nanoribbon;

[0018] Two, according to the ratio of the quality of graphene nanobelts and the volume of high-purity deionized water (5~20) mg: 1mL ratio, the graphene nanobelts that step one obtains is dispersed in high-purity deionized water, obtain graphene Nanoribbon printing solution...

specific Embodiment approach 2

[0019] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the mixed solution of concentrated sulfuric acid and concentrated phosphoric acid in step 1 is that the concentrated sulfuric acid with a mass percentage concentration of 98% and the phosphoric acid with a mass percentage concentration of 85% are pressed It is formulated with a volume ratio of (9-10): 1; the others are the same as in Embodiment 1.

specific Embodiment approach 3

[0020] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass ratio of multi-walled carbon nanotubes to potassium permanganate in step 1 is 1: (5-6). Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com