Six-axis spraying mechanical arm

A manipulator and six-axis technology, which is applied in the field of six-axis spraying manipulator, can solve the problems of large installation space, potential safety hazards, and bulky machines, and achieve the effects of reducing internal space, improving safety, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

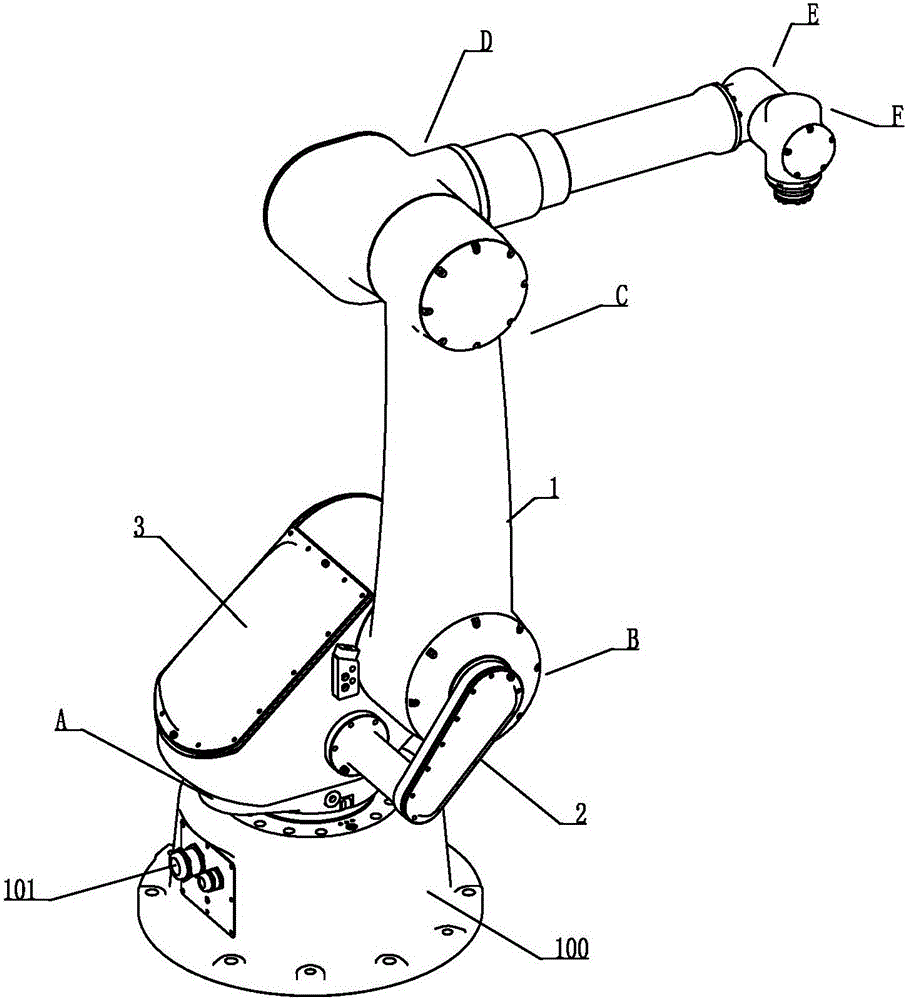

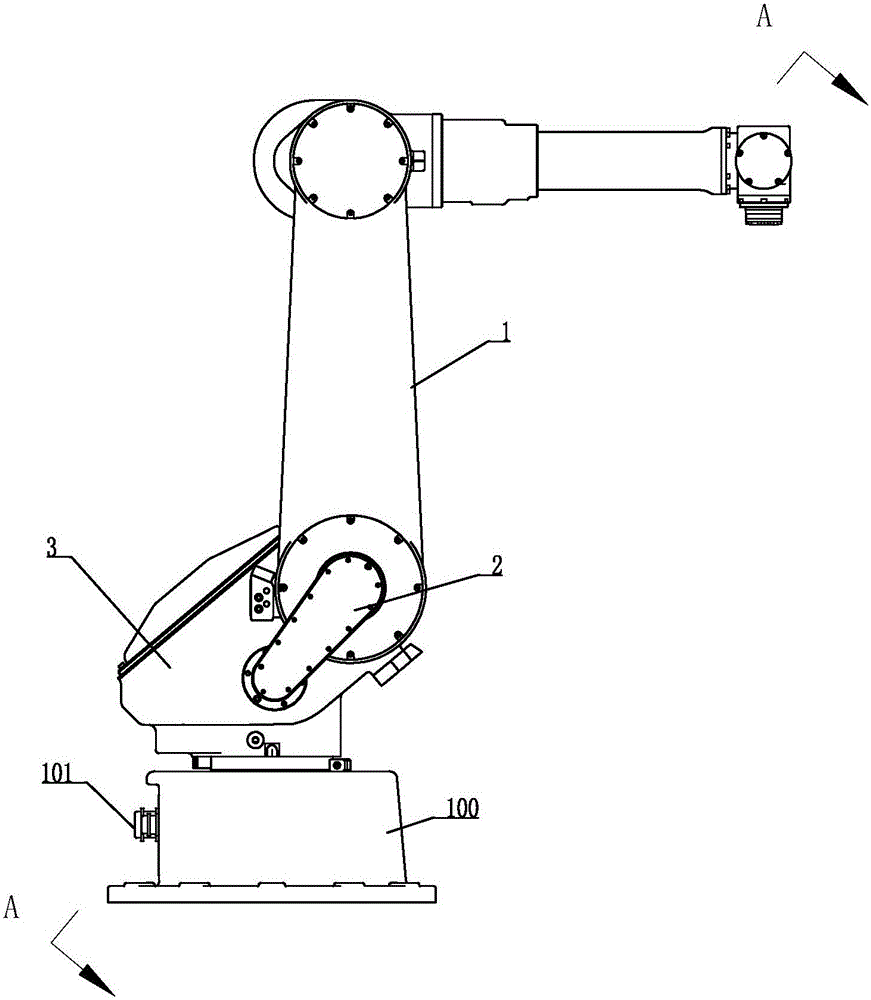

[0025] Such as figure 1 with figure 2 The shown six-axis spraying manipulator includes a base 100, and the base 100 is sequentially connected with a first transmission mechanism A, a second transmission mechanism B, a third transmission mechanism C, a fourth transmission mechanism D, a fifth transmission mechanism E and The sixth transmission mechanism F.

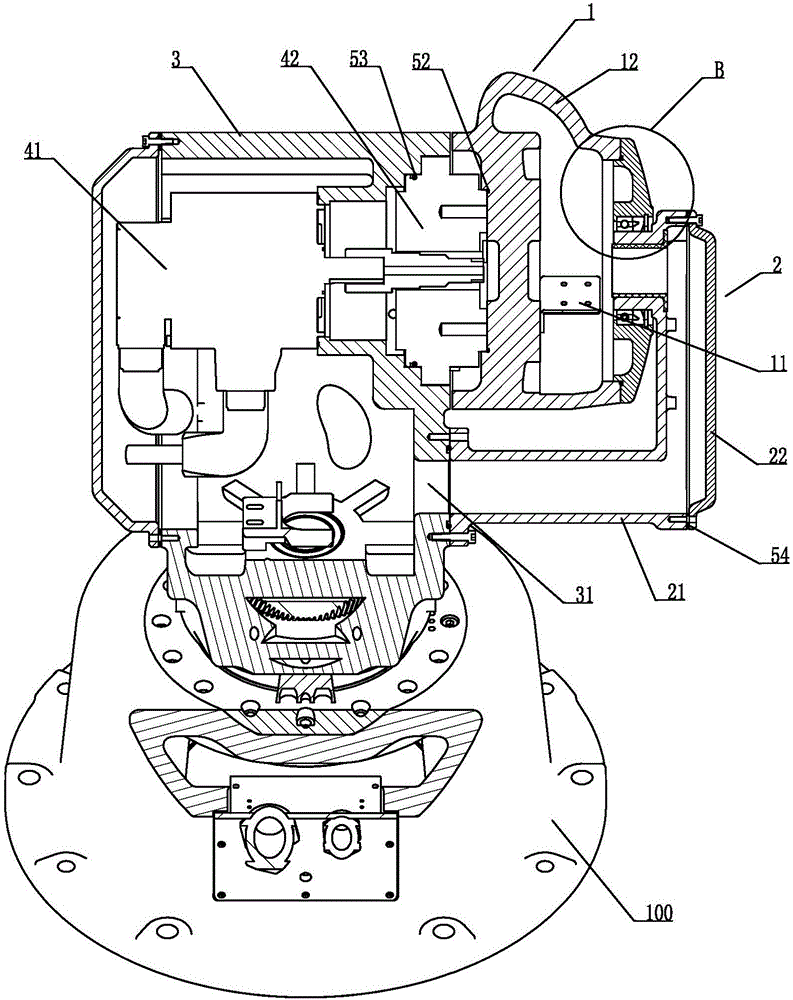

[0026] Each of the above-mentioned transmission mechanisms has a corresponding shell, and these shells are assembled and sealed to form the manipulator body in the embodiment, that is, it can be regarded as a closed equipment cavity formed inside the manipulator body, and the equipment cavity and the manipulator body The external gas is non-conductive, so inert gas can be filled in the equipment cavity to form a positive pressure to ensure the safety during the spraying process.

[0027] In addition, the above-mentioned transmission mechanisms are equipped with reducers respectively, and each reducer is also located in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com