Rapid cylinder assembling fixture for jack

A jack and fast technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of assembly failure, low efficiency, assembly failure, etc., and achieve the effect of eliminating deformation, convenient use and unique concept.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

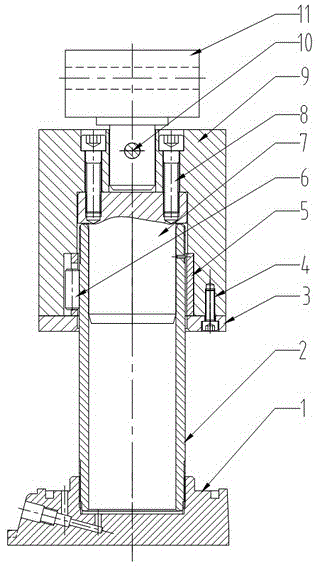

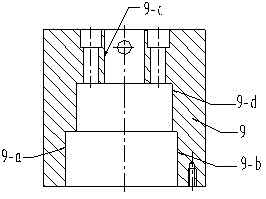

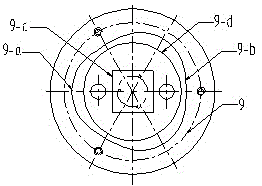

[0026] figure 1 Among them, the present invention includes coupling 11, clip body 9, mandrel 7, roller 6, roller limit bushing 5 and other components. The lower part of the coupling 11 is a cuboid, which is inserted into the square hole of the clamp body, and after being connected and fixed by the pin shaft 10, it plays the role of transmitting torque to the clamp body 9. The mandrel 7 is connected and fixed with the clamp body with screws, and the other end is packed into the oil cylinder. When the clamp body rotates, the mandrel rotates synchronously with it, and when the clamp body clamps the outer wall of the oil cylinder, it plays the role of supporting, bearing pressure, and transmitting the pressure of the outer wall of the oil cylinder 2, preventing the deformation of the inner hole of the oil cylinder, chamfering the front end, and preventing the oil from entering the oil cylinder. guiding role. The lower part of the clamp body is provided with a plurality of indepe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com