Sorting and dust-removing device used for capsules

A technology of dust removal device and sorting device, which is applied in the direction of separating solids from solids with airflow, solid separation, surface polishing machine tools, etc., which can solve the problem of feeding blockage, too much or too little capsule feeding, and sorting slow speed etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

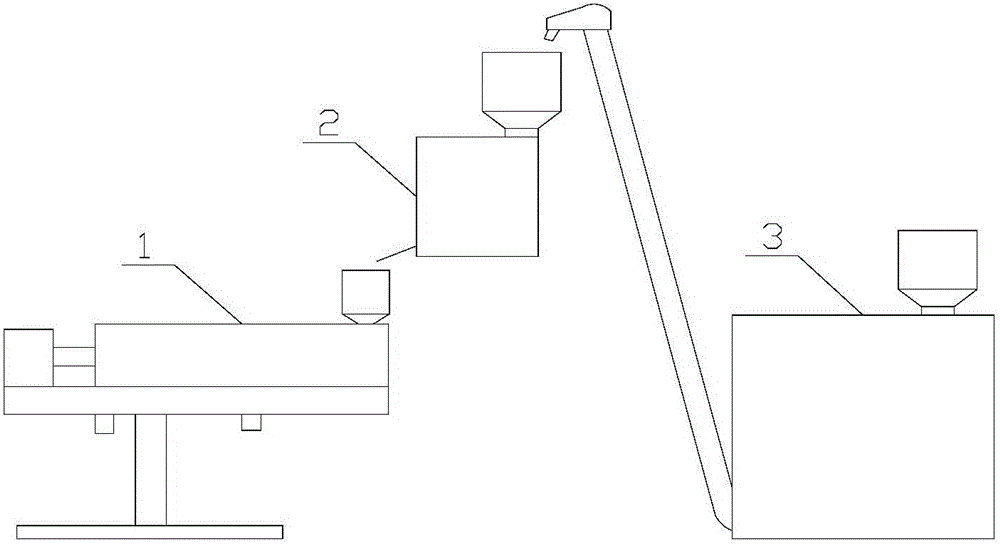

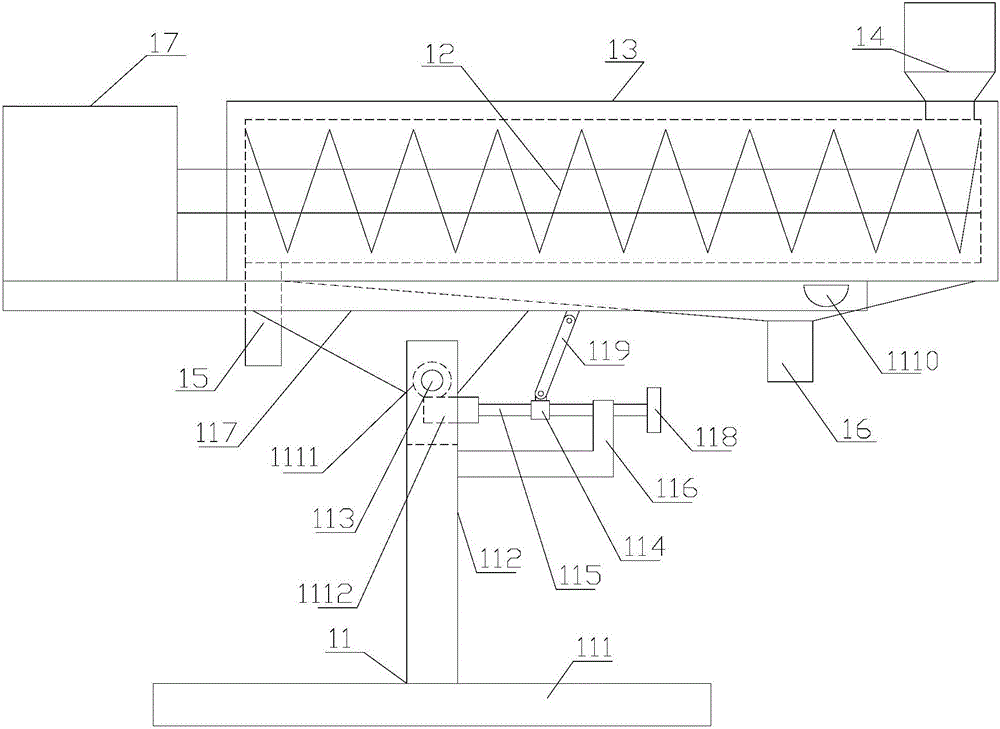

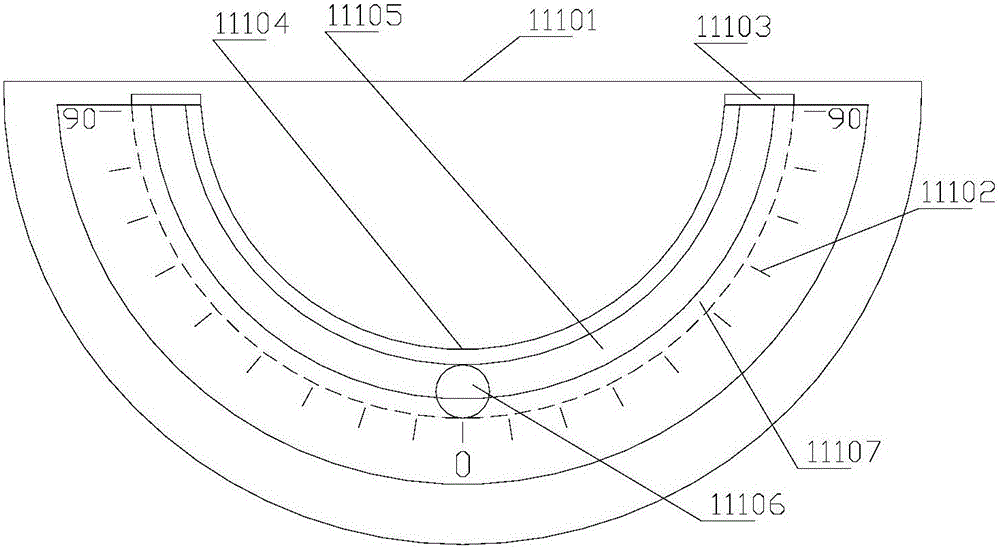

[0027] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 , a sorting and dedusting device for capsules of the present invention, comprising a polishing mechanism 1, a sorting device 2 and a feeding mechanism 3, the polishing mechanism 1, the sorting device 2 and the feeding mechanism 3 are arranged in sequence from front to back, so The polishing mechanism 1 includes a frame 11, a polishing brush 12, a polishing cylinder 13, a feed port 14, a discharge port 15, a powder suction port 16 and a first motor 17, and the frame 11 is provided with a polishing cylinder 13 and a first motor 17. A motor 17, the upper rear end of the polishing cylinder 13 is provided with a feed inlet 14, the front end bottom of the polishing cylinder 13 is provided with a discharge port 15, and the bottom of the polishing cylinder 13 is provided with a powder suction port 16, so The polishing cylinder 13 is provided with a polishing brush 12, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com