Quick and precise positioning clamp

A precise positioning and fast technology, used in positioning devices, clamping, manufacturing tools, etc., can solve the problems of high operation difficulty, single function, low efficiency, etc., to improve positioning accuracy, convenient operation, and prevent shaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

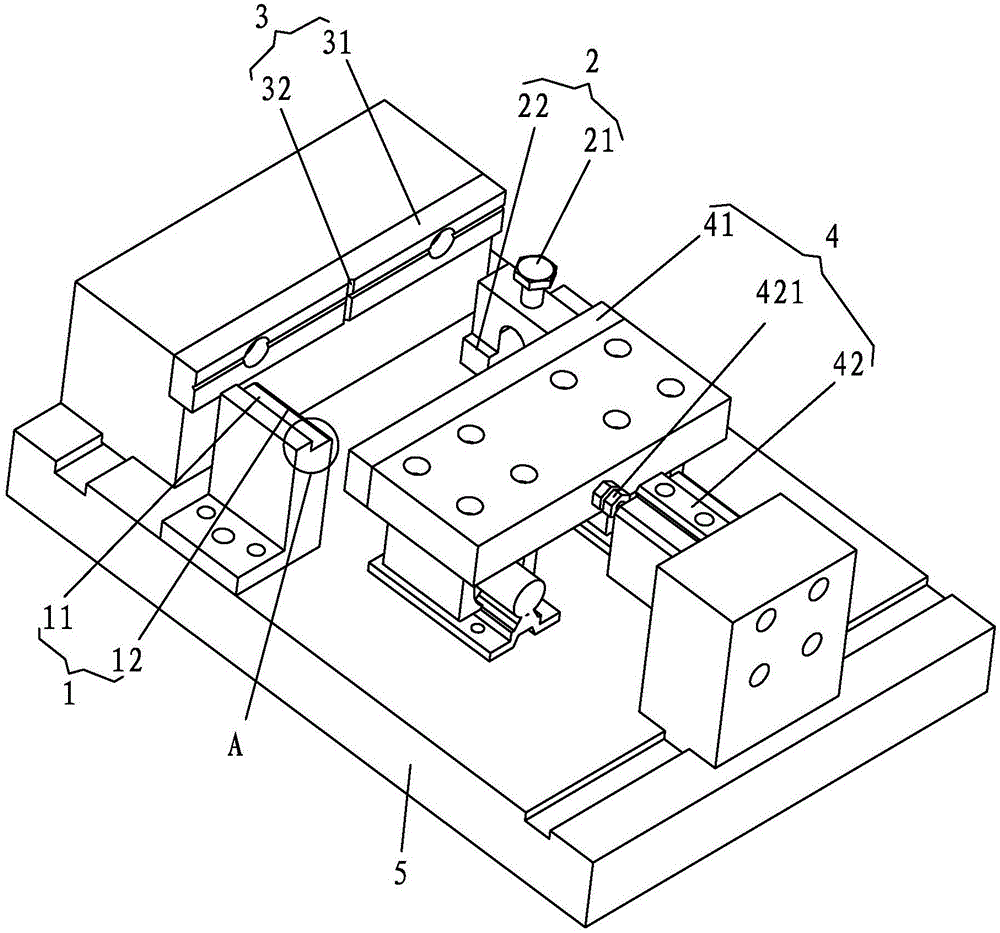

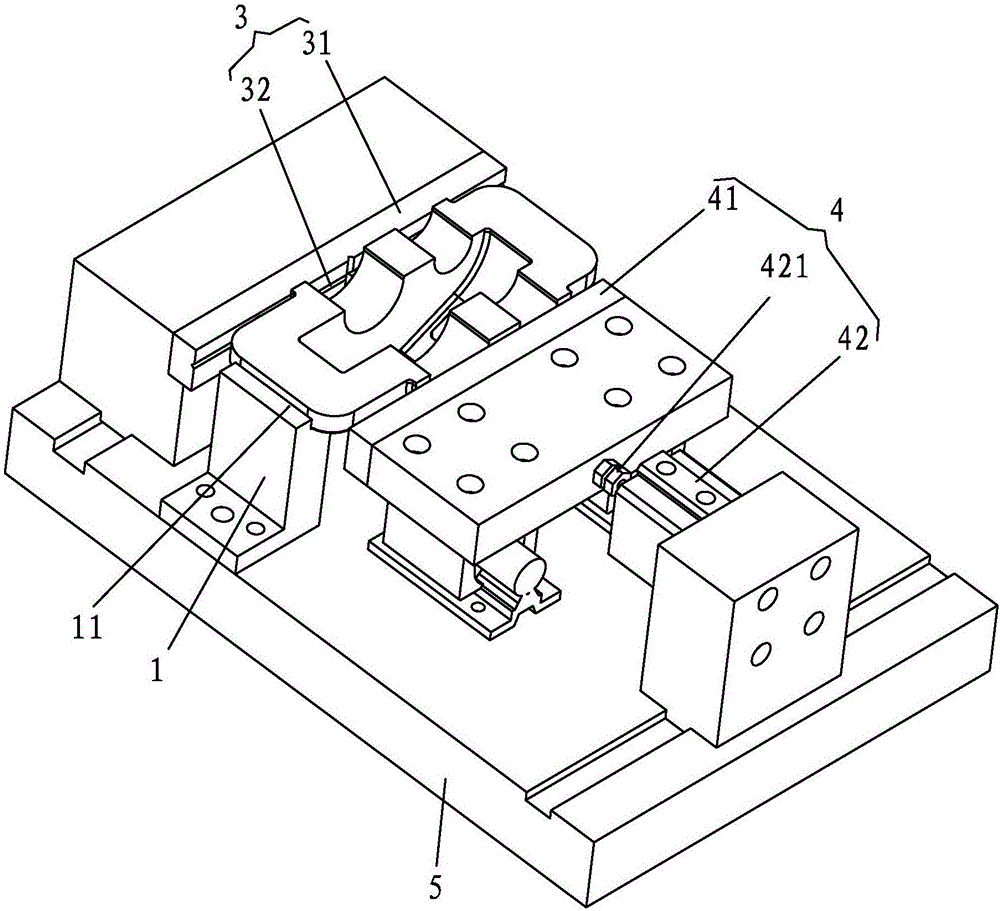

[0051] Such as Figures 1 to 4 As shown, the fast and accurate positioning fixture of the present invention mainly includes the correspondingly arranged first positioning body 1 and the second positioning body 2; Around the first positioning body 1 and the second positioning body 2 .

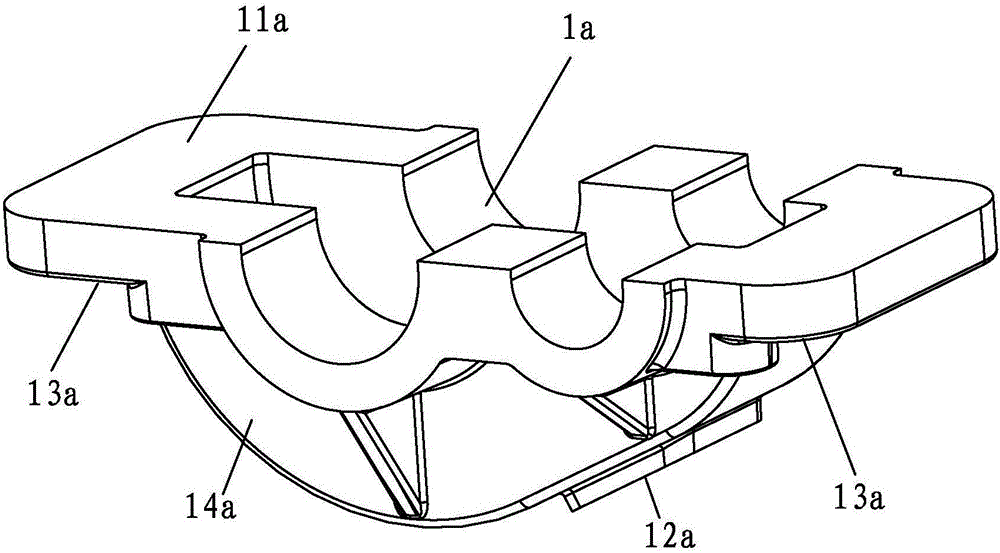

[0052] The first positioning body 1 is in the shape of a plate, with one end facing upwards, and a step is provided at the end, and the step forms a first support part 11, and the first support part 11 is composed of a continuously bent horizontal step surface, a vertical step surface and a horizontal step face composition. A first positioning slope 12 is formed at the outer edge of the horizontal step surface of the first supporting portion 11 , and the first positioning slope 12 forms a first positioning angle α with the hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com