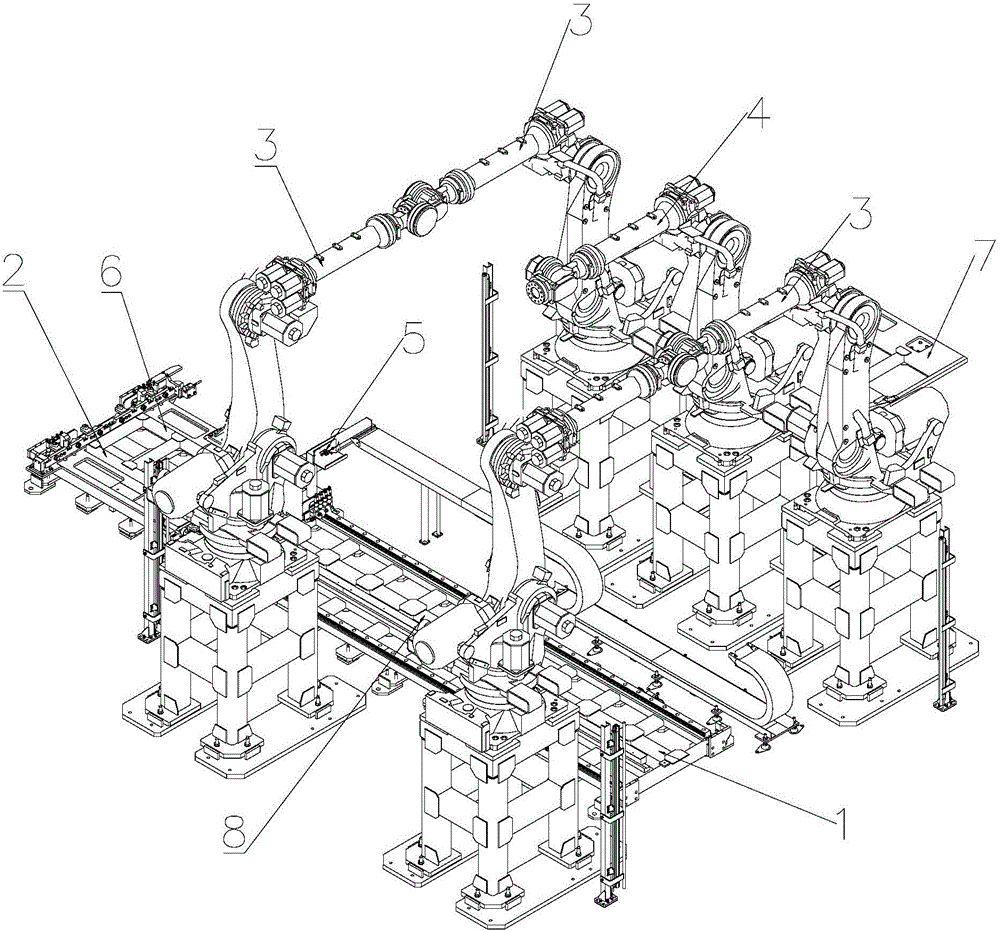

Intelligent flexible welding system

A welding system, intelligent and flexible technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unsuitability for domestic manufacturers and high technical costs, reduce unstable factors and improve welding production quality Guarantee and improve the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

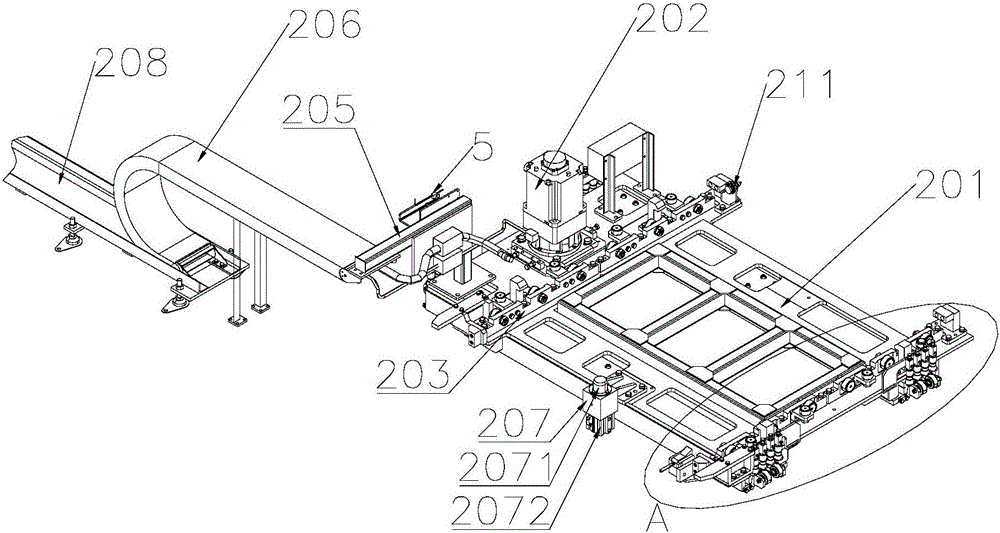

[0028] The present invention and the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

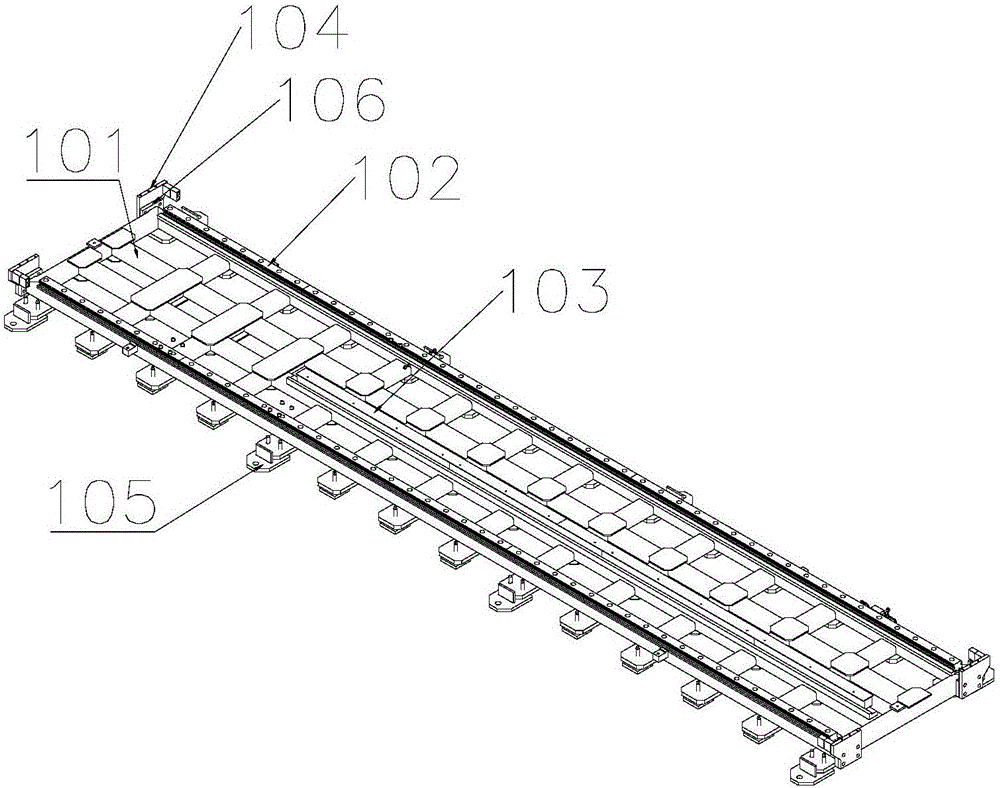

[0029] Such as figure 1 , 2 As shown, an intelligent flexible welding system includes a base mechanism 1. The base mechanism 1 includes a base body 101. The upper surface of the base body 101 is provided with two base slide rails 102. The two base slide rails 102 are along the length direction of the base body 101 and mutually The cross section of the base slide rail 102 is I-shaped; the base rack 103 is fixedly installed on the upper surface of the base body 101, and is arranged parallel to the base slide rail 102; the slide mechanism 2 is installed on the base slide rail 102, along the The base slide rail 102 slides; the two ends of the base body 101 are also equipped with an overtravel limiting device 104 .

[0030] The base body 101 is welded by profiles such as square tubes or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com