A kind of production process of saw blade substrate

A production process and substrate technology, applied in the production process field of saw blade substrate, can solve the problems of incomplete elimination of residual stress, affecting the quality of saw blades, low product accuracy, etc., to eliminate internal residual stress, long service life, production simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

[0037] A production process of a saw blade base, which comprises the following steps:

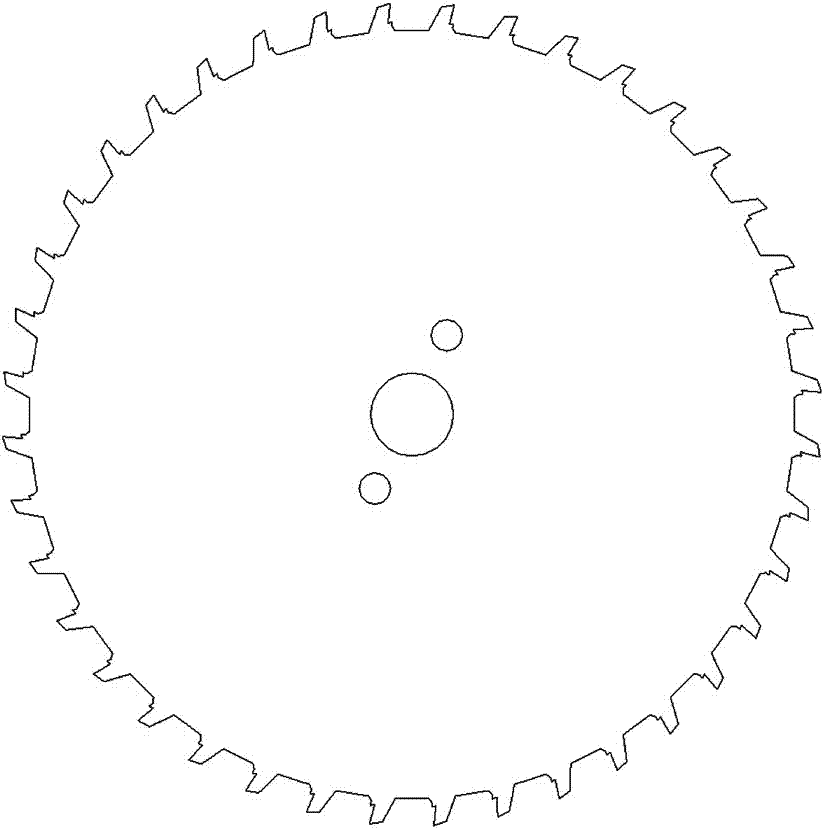

[0038] S1. Draw the outer contour of the saw blade base on the steel plate, use laser cutting to cut along the ring line, and make a shaped saw blade base, and polish the surrounding teeth of the shaped saw blade base to remove the debris generated during the cutting process scale and burrs;

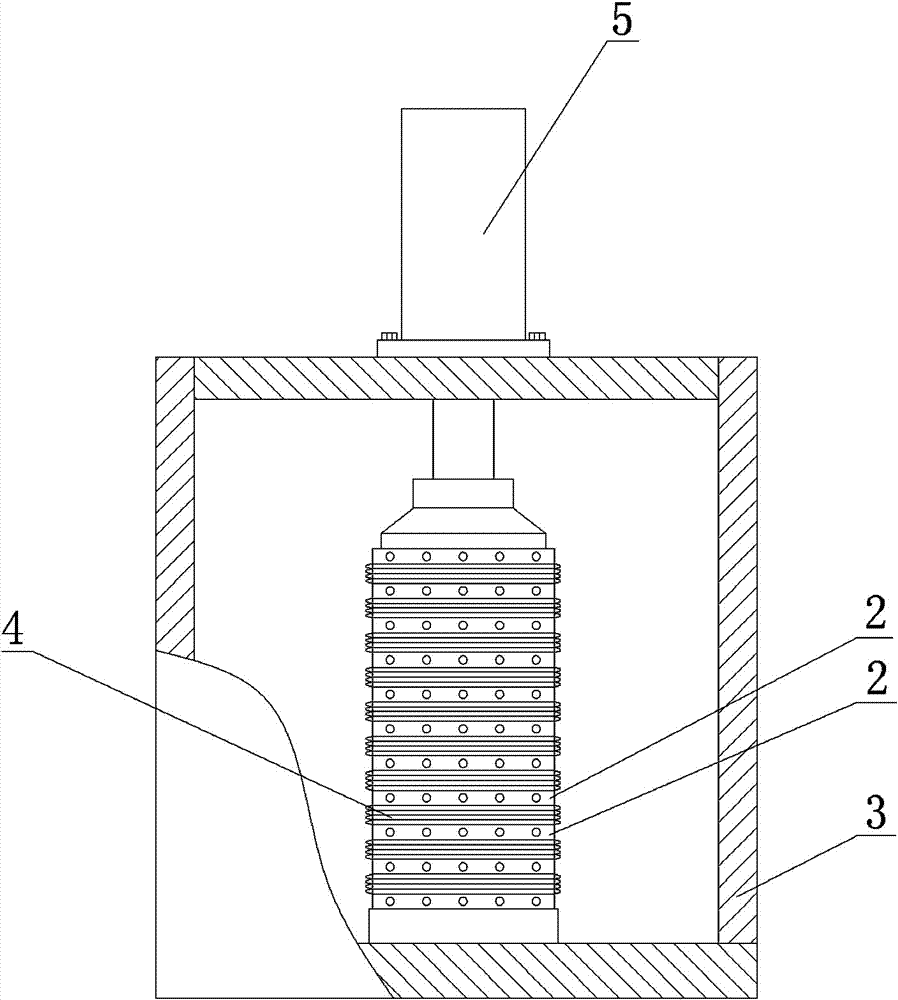

[0039] S2, such as Figure 3~5 As shown, the leveling and tempering treatment, the specific operation steps are as follows:

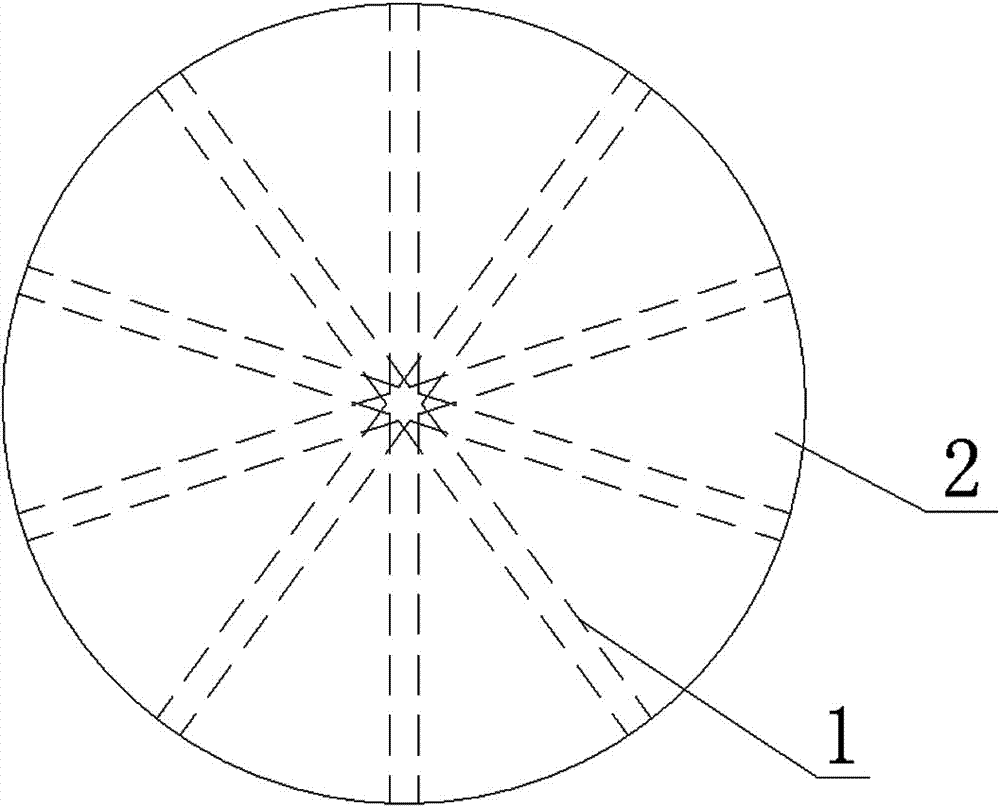

[0040] S(2a), such as figure 2 As shown, to make the pressing plate, a solid disc with a certain thickness is used, and a plurality of heat conduction holes 1 evenly distributed and penetrating the solid disc are opened on the cylindrical surface of the solid disc, thereby realizing the production...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com