High-speed metal cutting circular saw

A technology of metal cutting and circular sawing machine, which is applied in the direction of metal sawing equipment, metal processing equipment, sawing machine equipment, etc., can solve the problem of no increase in sawing speed, achieve improved cutting accuracy, reasonable design, and stable and reliable feeding process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

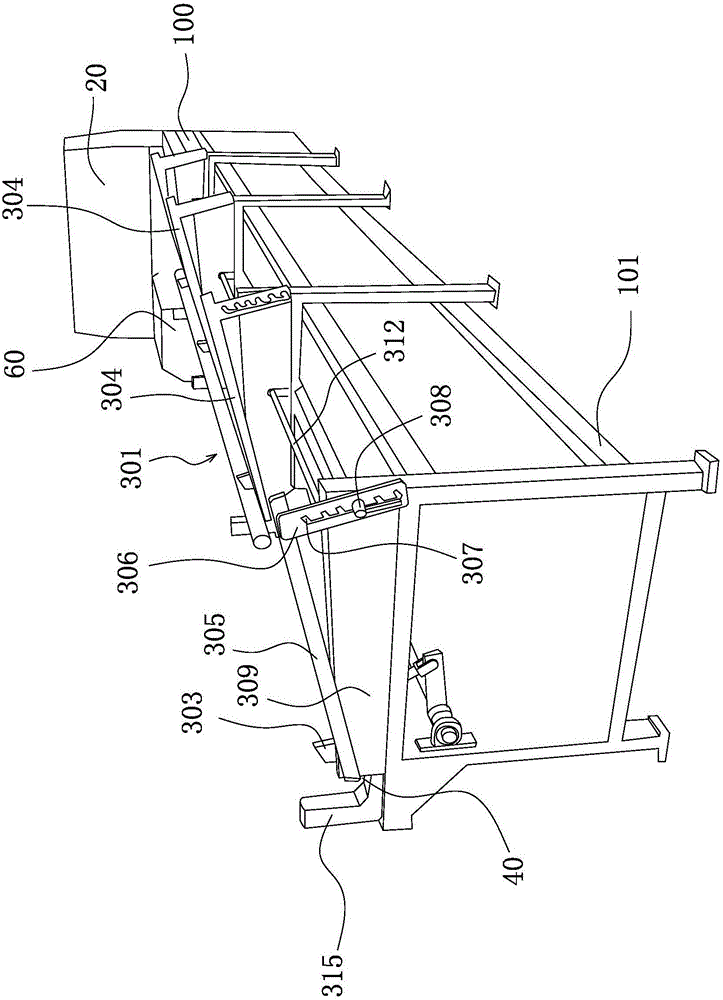

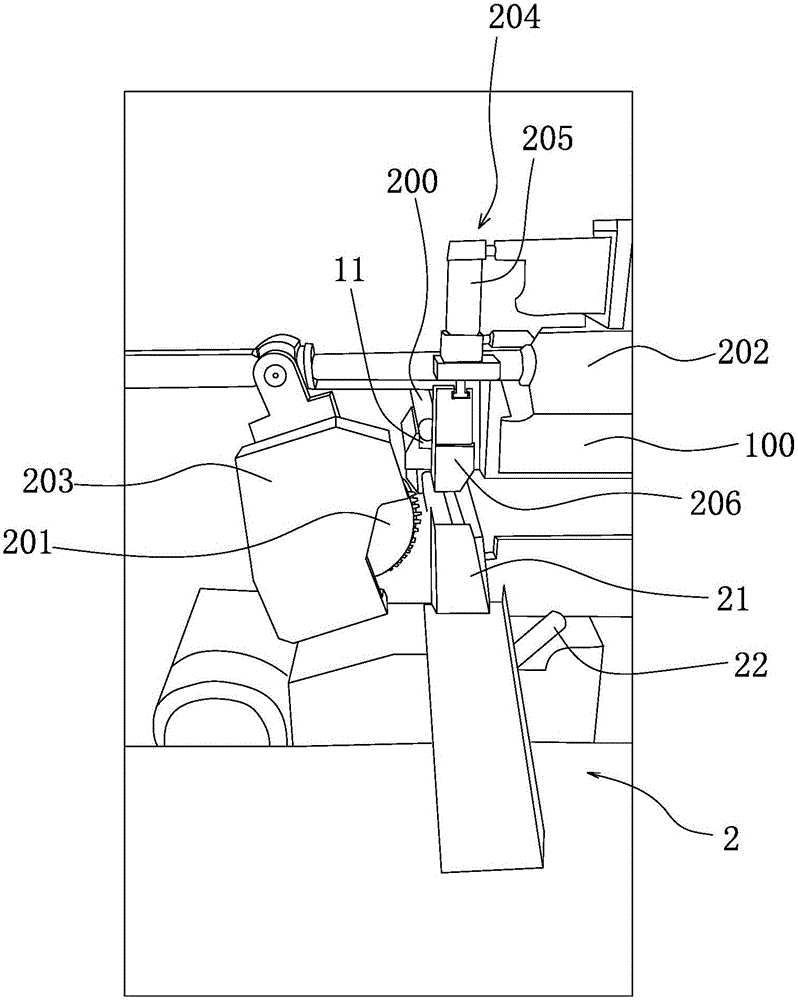

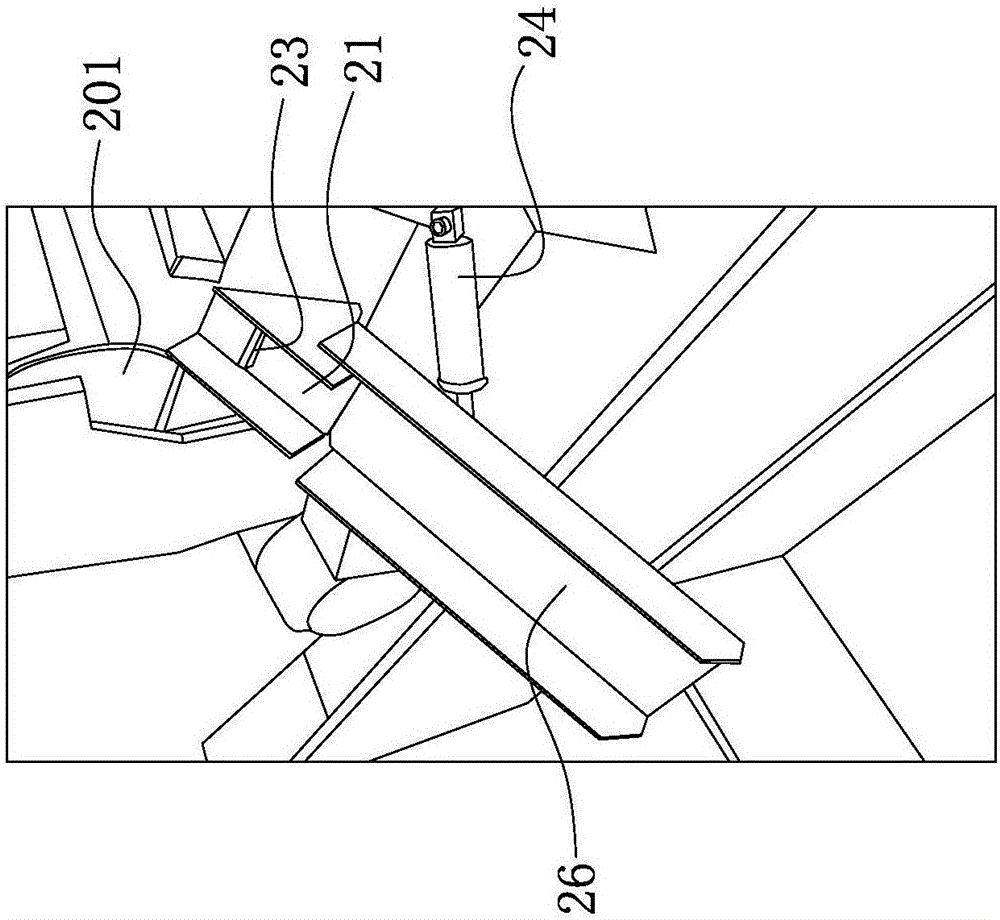

[0030] Such as Figure 1-4 As shown, a high-speed metal cutting circular saw machine includes a base 100, the base 100 is provided with a cutting mechanism 20, the base 100 is connected with a feeding mechanism 60, and the cutting mechanism 20 includes a cutting Sheet 201 and the cutting sheet driver (not shown) that is drivingly connected with cutting sheet 201, the cutting sheet driver is preferably a hydraulic motor, also can be a motor, on the support 100 is provided with a tool that can reciprocate along the axial direction The cutting seat driver 202 at the output end of the cutting seat 201 is arranged in the cutting seat 203 and is movably connected with the cutting seat 203, the bottom of the cutting seat 203 is hinged with the machine base 100, and the top of the cutting seat 203 is hinged with the output end of the cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com