High-temperature atomization sprayer

An atomizing nozzle and high temperature technology, applied in the direction of spray device, spray device, etc., can solve the problems of scalded skin, electricity consumption, poor heating effect of Yuba heater lamp, etc., and achieve the effect of less hot water consumption and water saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

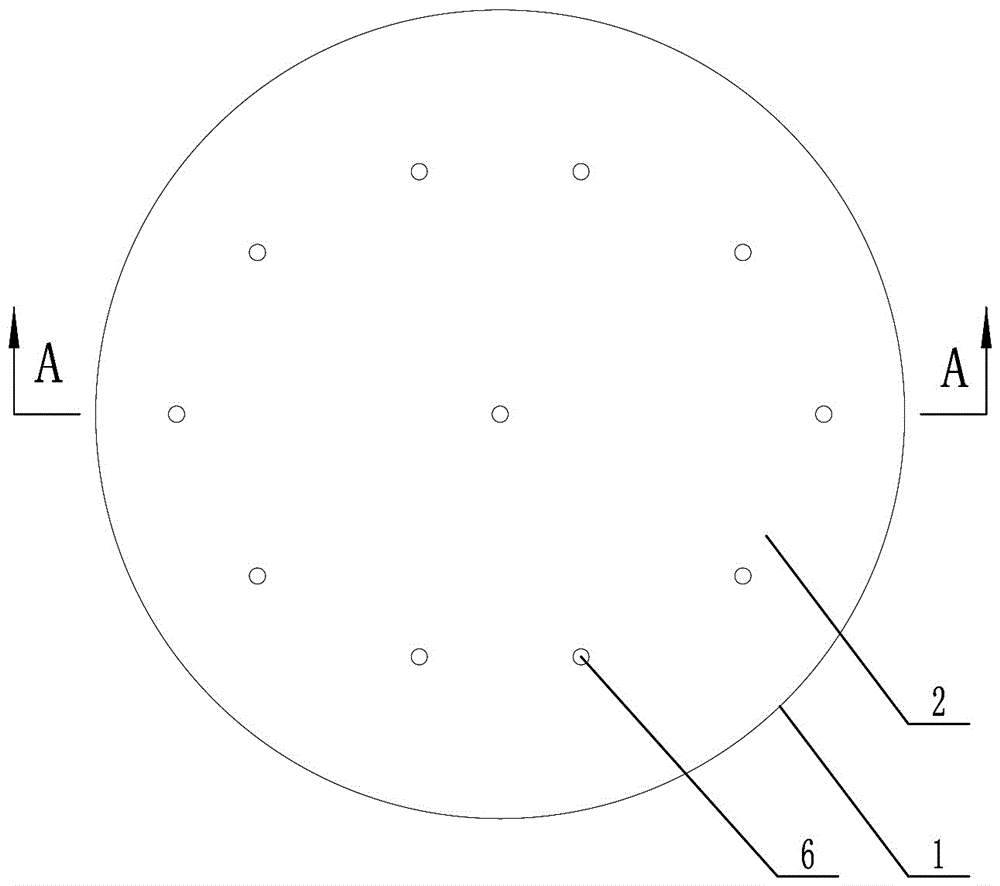

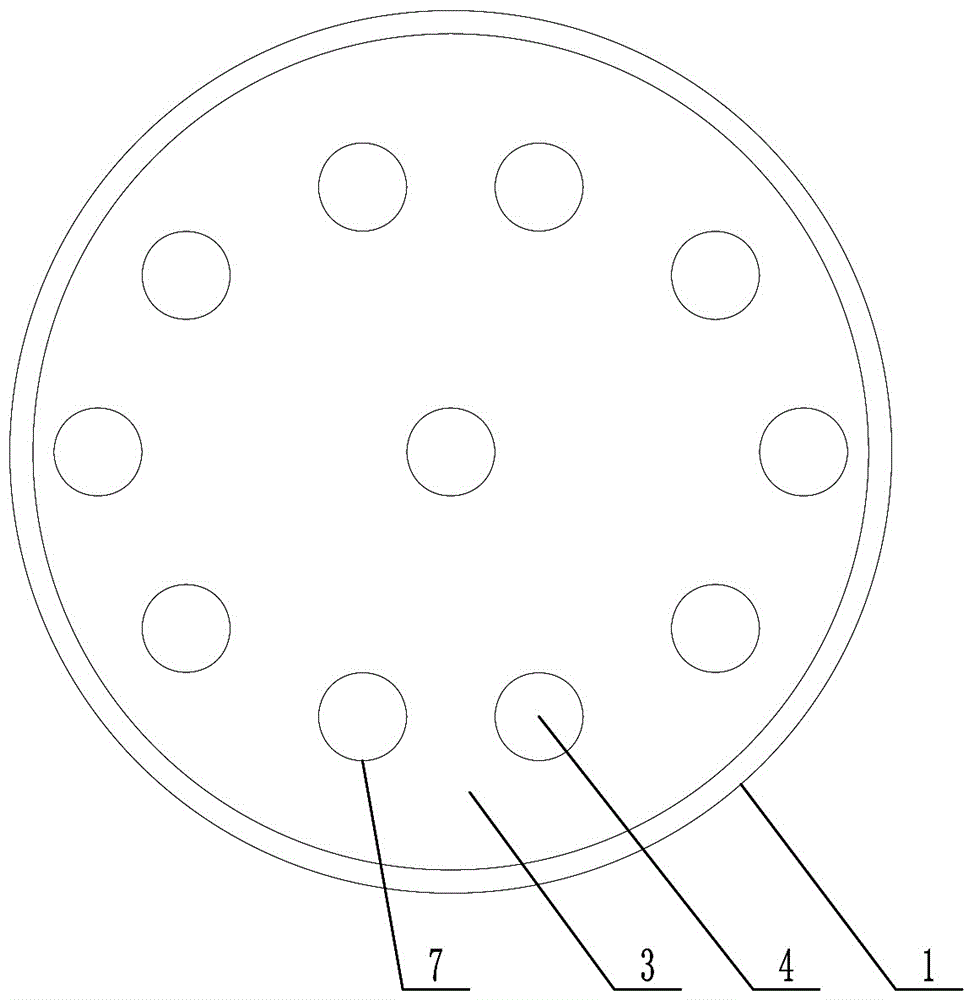

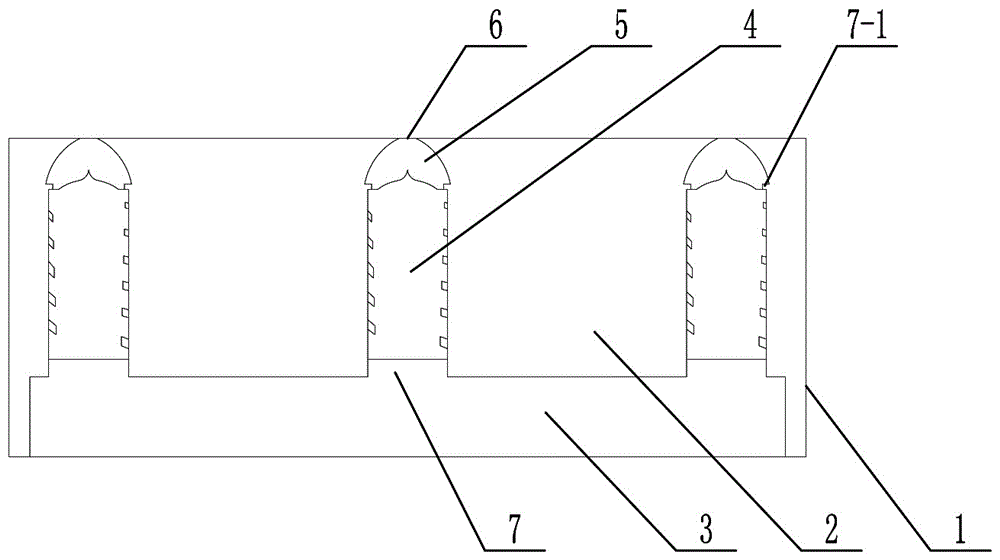

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a specific embodiment of a high-temperature atomizing nozzle of the present invention includes a main body 1, a sealed water chamber 3 and a nozzle 2 are arranged in the main body 1, and one end of the sealed water chamber 3 is connected with an external water source, and the sealed water The other end of the chamber 3 communicates with the spray head 2. The spray head 2 includes a sprayer 4, a spray chamber 5 and a water outlet 6. The sprayer 4 is provided with three or four uniformly distributed spiral pressurized water guide grooves 4- 1. In particular, the mutual impact acceleration effect of the four uniformly distributed helical pressurized water guides 4-1 is more obvious and effective. At the same time, the processing difficulty of the nozzle 4 is not too high, which is convenient for production. The spiral pressurized water guides 4-1 communicates with the sealed water chamber 3 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com