Recycling method of slurry-bed hydrocracking catalyst for heavy oil

A hydrocracking and suspension bed technology, applied in physical/chemical process catalysts, chemical instruments and methods, catalyst regeneration/reactivation, etc., can solve the problems of easily damaged catalyst structure, poor economic recovery of spent catalyst, long extraction process, etc. problems, to achieve significant economic benefits and environmental protection effects, cost reduction, and pollution reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

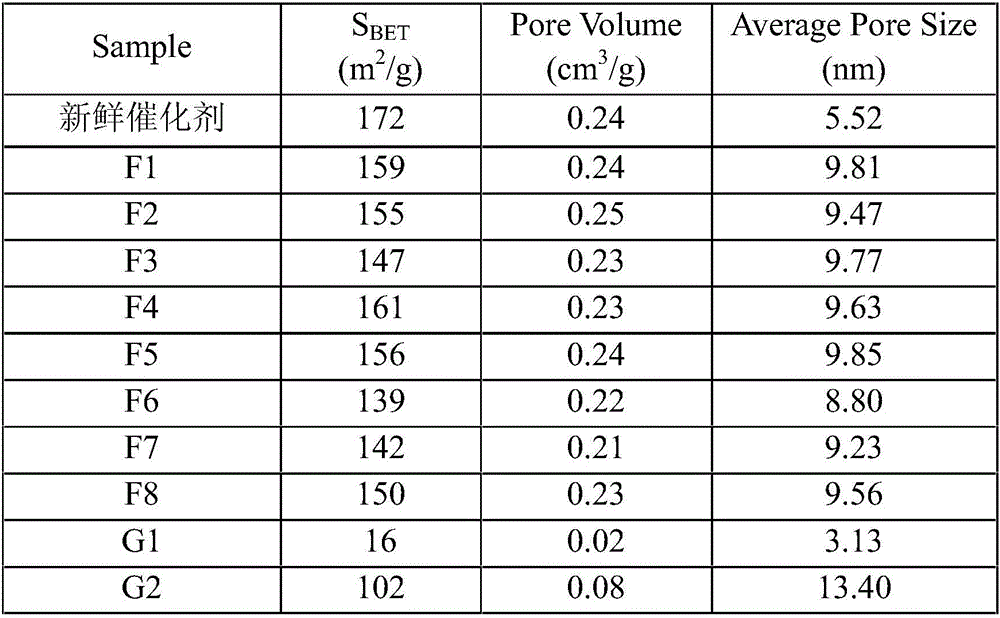

Embodiment 1

[0041] In the suspension bed hydrocracking unit, after a certain amount of medium-temperature coal tar and catalyst are reacted at 440°C and 22MPa, the tail oil after the high-pressure separator is collected, and the solids in the lower part of the centrifuge tube are collected by centrifugal separation technology. The collected solid was then dissolved with toluene as a solvent, heated to boiling, and continuously extracted in a Soxhlet extractor until the upper solvent was clarified. The solvent-insoluble material was dried in a vacuum drying oven at 110° C. for 4 hours, then heated to 500° C. in a tube furnace and calcined for 2 hours to obtain recovered catalyst F1.

Embodiment 2

[0043] In the suspension bed hydrocracking unit, after a certain amount of high-temperature coal tar reacts with the catalyst at 440°C and 22MPa, the tail oil after the high-pressure separator is collected, and the solids in the lower part of the centrifuge tube are collected by cyclone separation technology. Then dissolve the collected solid with petroleum ether solvent, and heat it to boiling in a Soxhlet extractor to continuously extract until the upper solvent is clear. Then, the solvent-insoluble material was dried in a vacuum oven at 110° C. for 4 hours, and then heated to 550° C. in a tube furnace and calcined for 4 hours to obtain recovered catalyst F2.

Embodiment 3

[0045] In the suspension bed hydrocracking unit, after a certain amount of vacuum residue and catalyst are reacted at 440°C and 22MPa, the tail oil after the high-pressure separator is collected, and the solids in the lower part of the centrifuge tube are collected by centrifugal separation technology. Then dissolve the collected solid with V (toluene): V (ethanol) = 1:1 mixed solvent, and heat to boiling in a Soxhlet extractor to continuously extract until the upper solvent is clear. The solvent-insoluble material was then dried in a vacuum oven at 110° C. for 4 hours, and then heated to 550° C. in a tube furnace and calcined for 8 hours to obtain recovered catalyst F3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com