Amine liquid foaming device

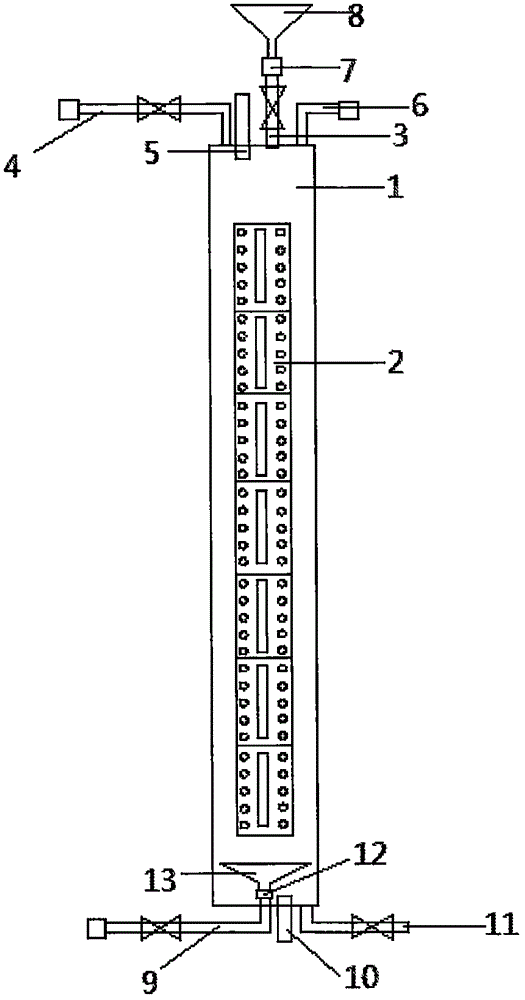

A foaming device, amine liquid technology, applied in the directions of transportation and packaging, dissolution, chemical instruments and methods, etc., can solve the problems of degradation, corrosion of production equipment and transportation pipelines, amine liquid foaming, etc., and achieve the realization of size and speed. The effect of adjusting, increasing the contact area, and facilitating disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

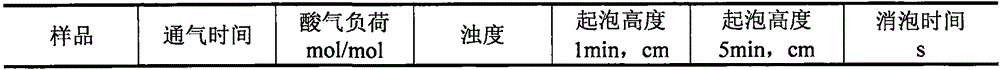

[0027] From the foaming device 8, add 100 mL of different turbidities from the site and prepare the absorption solution containing 47% (w / w) methyldiethanolamine, set the system temperature to 50 ° C, and set the flow rate to 300 mL / min. The on-site raw natural gas was introduced into the pipeline 9 for 1h, 2h, and 3h, and the control pressure was 5MPa to make rich liquids with different acid gas loads. Based on this, the influence of acid gas loads on the foaming ability of amine liquids was studied. Record 1min, After the foaming height of 5 minutes was stopped, the defoaming time was recorded. The specific experimental results are shown in Table 1.

[0028] Table 1 Analysis results of the influence of acid gas load and turbidity in amine liquid on the foaming ability of amine liquid

[0029]

[0030]

Embodiment 2

[0032] From the foaming device 8, add the rich liquid that participated in the operation in the acid gas absorption system collected at different times on site, set the temperature at 50°C, and at a flow rate of 300mL / min, feed the on-site raw natural gas through the pipeline 9 for 1 hour, and control The pressure is 5MPa, the chemical volumetric method is used to analyze the hydrogen sulfide and carbon dioxide content in the rich liquid, and the acid gas load in the amine liquid in the system operation is calculated. The influence of the acid gas load on the foaming height and defoaming time of the amine liquid in the system operation is shown in the table 2.

[0033] Table 2 Effect of acid gas load on foaming height of amine liquid during system operation

[0034]

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com