Clean diary cow water feeding and feed feeding system

A feeding system and cleaning technology, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, animal feeding devices, etc., can solve the problems of difficult feeding, inconvenient cleaning, and a lot of labor, so as to solve the problems of large labor and high efficiency. The effect of inconvenient cleaning and avoidance of feed waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

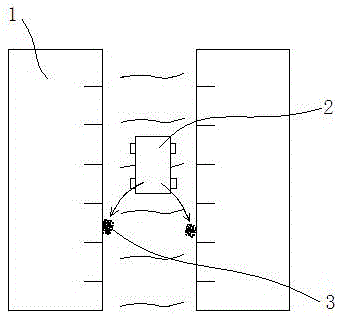

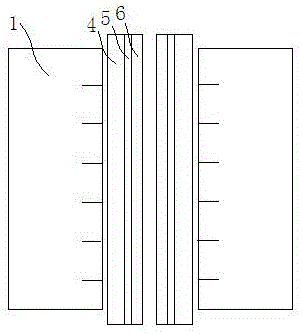

[0026] Accompanying drawing is a kind of specific embodiment of the present invention.

[0027] like figure 2 , 3 , 4, and 5, this embodiment includes a sunken feeding channel 4 that is located on the outside of the fence 1 and can accommodate water or feed, and the outside of the feeding channel is connected with an arc-shaped cover 6 through a hinged shaft 5. , after the arc-shaped cover is closed, it can form a closed pipeline with the feeding channel; a bracket 7 is provided on the inner side of the feeding channel, and two slide rails 8 are erected through the bracket. The material leakage area 9 directly above is also provided with a discharge control head 10 that is located between the two slide rails and can move along the two slide rails. The discharge control head is connected to the material source through a pipeline, and can control the feed falling into the feeder. Inside the feed canal.

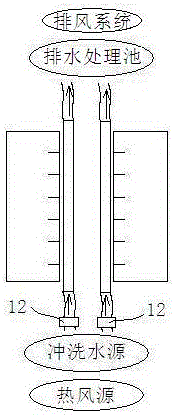

[0028] One end of the feeding channel is connected to the flushing wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com