Automatic seed covering seedling raising substrate plate for rice and preparation method and application

A seedling raising substrate and automatic covering technology, applied in the field of rice seedling raising, can solve the problems that seedlings are prone to produce aerial roots and aquatic roots, affect yield, quality and maturity period, and cannot guarantee the integrity of mechanical transplanting, so as to achieve significant ecological benefits and reduce The effect of capital investment and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

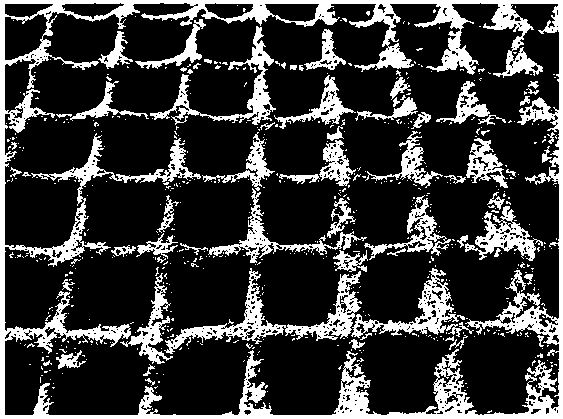

Image

Examples

preparation example Construction

[0045] The present invention provides the preparation method of described seedling raising matrix plate, comprises the following steps:

[0046] 1) Prepare puffed rice husk, broken pieces of corn stalks, decomposed manure, grass carbon soil and vermiculite with water to make a slurry, adjust the acidity to 4.5-5.0, and prepare a disk-making slurry;

[0047] 2) The disc-making slurry is sucked into a mould, dried and solidified at 250-270° C. to obtain the initial shape of the seedling-raising matrix disc;

[0048] 3) Holes are punched on the degradable paper according to the distribution positions of the cavities in the seedling-raising matrix tray, and the degradable paper punched with holes is wrapped and glued on the bottom surface and side wall of the seedling-raising matrix tray prototype to obtain a seedling-raising matrix tray.

[0049] In the invention, the expanded rice husk, broken pieces of corn stalks, decomposed excrement, grass carbon soil and vermiculite are pre...

Embodiment 1

[0062] Component Preparation Method:

[0063] 1. Preparation of puffed rice husk: Pass the rice husk through a sieve of 6-8mm, clean and remove impurities, puff it with an extruder at a temperature of 350° C., collect the puffed product to obtain puffed rice husk.

[0064] 2. Preparation of broken pieces of corn stalks: drying the corn stalks, pulverizing them, sieving, and collecting broken pieces of corn stalks with a fineness below 10 mm.

[0065] 3. Preparation of decomposed cow dung: adjust the water content of the cow dung to 45%, pile the cow dung into a trapezoidal body, turn the pile when the central temperature of the cow dung is higher than 55°C, and turn the pile once every 3 days for a total of 4 times. Ferment the turned cow dung under closed conditions for 20 days to obtain decomposed cow dung.

[0066] 4. Preparation of fine grass carbon soil: pulverize the purchased grass carbon soil, sieve, and collect the undersieve to obtain fine grass carbon soil.

[00...

Embodiment 2

[0069] 1. Weigh according to the following weight: 35kg puffed rice husk, 35kg crushed corn stalks, 15kg fine grass carbon soil, 15kg decomposed cow dung and 20kg vermiculite.

[0070] 2. Preparation method of automatic covering matrix disc

[0071] Mix puffed rice husk particles, crushed corn stalks, decomposed cow dung, vermiculite, and peat materials according to the above ratio. Mix every 1 kg of dry material with 40 kg of water, while mixing, spray an appropriate amount of diluted acid solution to adjust the pH value to 5.0. Then pump the prepared mixed slurry into the slurry tank of the plate making machine, use the mold to absorb and form, and dry with 260°C high-temperature hot air to obtain the prototype. The initial type is prepared according to the specification of rice seedling tray 280 × 580mm in the universal type dry nursery machine, and is prepared into specifications of width 280 × length 580mm, thickness 20mm (the thickness of the bottom of the cavity is 10m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com