Filter element with multi-stage water-separating action and with bayonet connection, and fuel filter having a filter element of said type

A filter element and filter technology, applied in membrane filters, fixed filter element filters, filter circuits, etc., can solve problems such as unfavorable maintenance, filter element consumption, etc., to reduce maintenance costs, shorten motor start-up time, avoid trash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

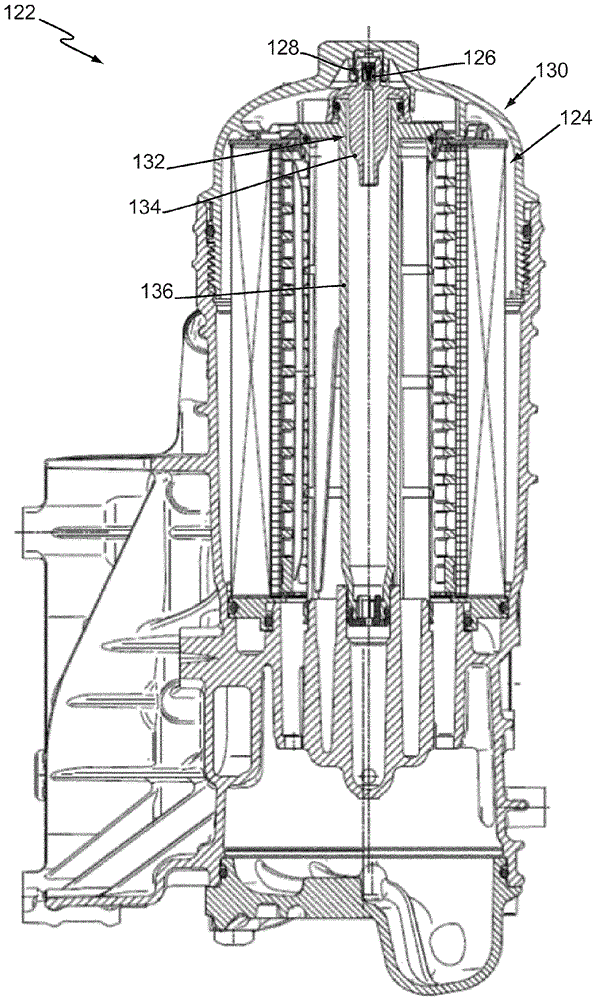

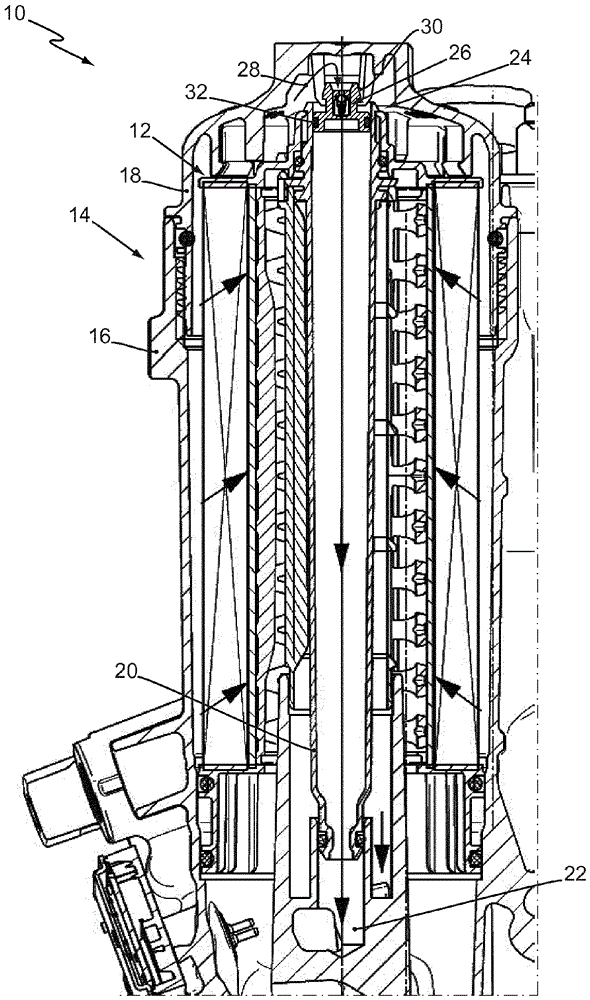

[0040] figure 1A first fuel filter 10 is shown with a first filter element 12 for multi-stage cleaning of fuel. The first filter element 12 is arranged in a filter housing 14 of the first fuel filter 10 . The filter housing 14 has a filter bowl or filter housing 16 . A cover 18 of the filter housing 14 is screwed onto the filter housing 16 .

[0041] The first filter element 12 has a ventilation tube 20 . Air can be conducted from the first fuel filter 10 via the ventilation line 20 back into the canister (not shown) via the return 22 . A non-return valve 26 is arranged on an end 24 of the ventilation line 20 opposite the return flow 22 . The non-return valve 26 opens in the direction of the return 22 or arrow 28 at an excess pressure of greater than approximately 0.4 bar. Non-return valve 26 can thus be easily opened, so that air can be led off quickly from first fuel filter 10 . In this case, the air is removed in the direction of the arrow 28 . The non-return valve 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com