Fault information sampling device

A sampling system and fault information technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of low detection accuracy, affecting faults, and the detector cannot detect gas, so as to achieve accurate analysis and judgment of faults and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

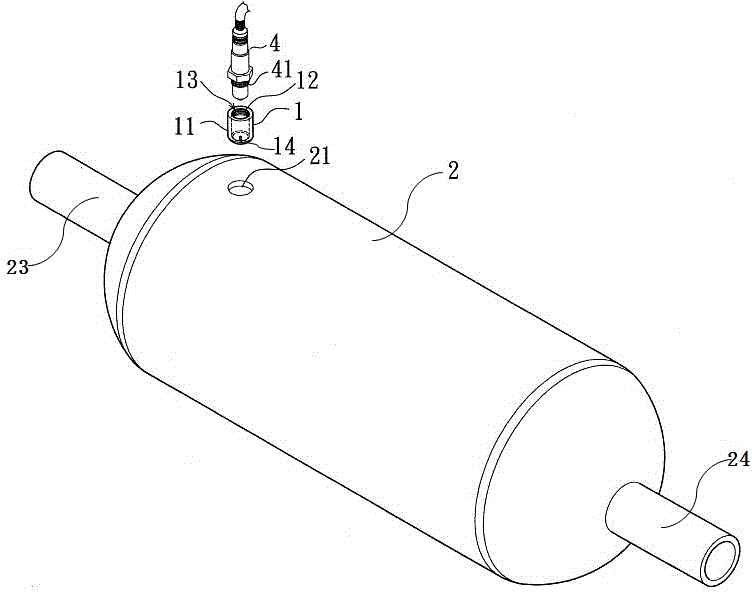

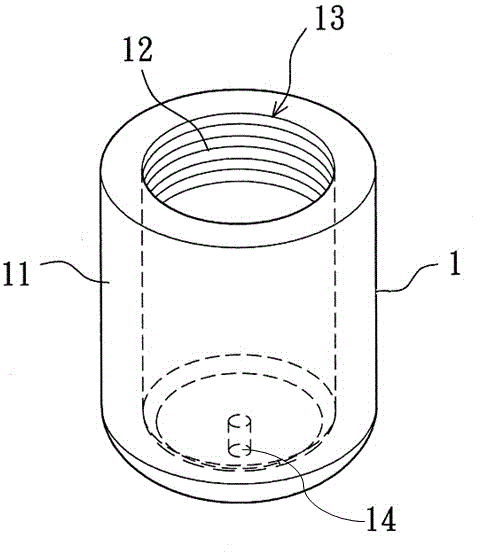

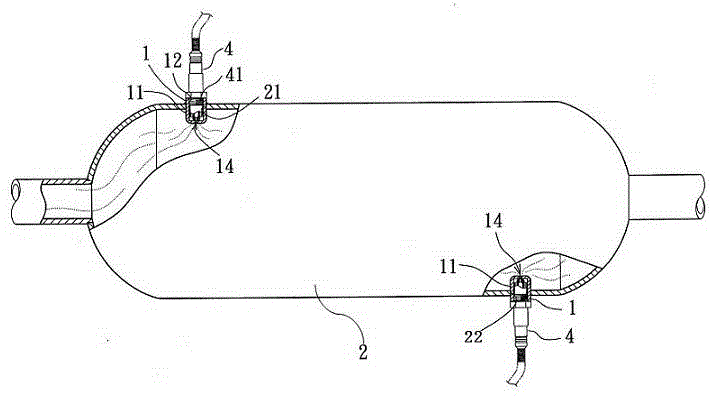

[0015] like figure 1 and image 3 As shown, the fault information sampling system of this embodiment includes a base 1, a converter 2 and a detector 4. The converter 2 is a cylinder, and a catalyst is provided inside the converter 2 for purifying the gas. The converter 2 includes a front-end pipe 23 and a rear-end pipe 24 at both ends, and the gas enters from the front-end pipe 23 and is discharged from the rear-end pipe 24 . The converter 2 is provided with a first hole 21 and a second hole 22 near the front and rear end pipes. In this embodiment, the first and second holes 21 and 22 are arranged on the surface of the cylinder of the converter 2 . The base 1 is respectively disposed in the first hole 21 and the second hole 22 , and the detector 4 is disposed in the base 1 . The base 1 includes a sleeve 11 with an internal thread 12 inside. The upper end of the slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com