A complete set of garbage disposal equipment

A complete set of equipment and waste treatment technology, applied in lighting and heating equipment, combustion types, combustion methods, etc., can solve problems such as unsatisfactory economic benefits, secondary pollution, and huge construction investment, and achieve the goal of suppressing dioxins. The effect of forming, improving the waste combustion value, and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

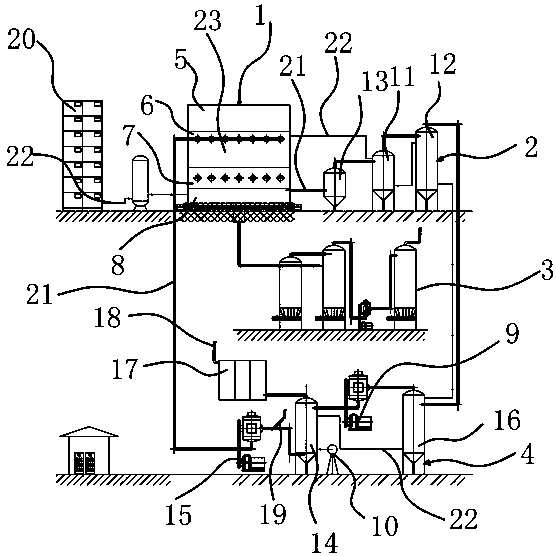

[0029] Such as figure 1As shown, the complete set of waste treatment equipment includes: pyrolysis gasification combustion system 1, the pyrolysis gasification combustion system 1 is the core component of the whole set of equipment, and its appearance is a closed warehouse structure. The pyrolysis gasification system is connected to the circulating water cooling heat exchange system 2 through the gas transmission pipeline 21, and the gas formed after the pyrolysis and gasification of the garbage can be transported to the circulating water cooling heat exchange system 2 through the gas transmission pipeline 21; specifically, The pyrolysis gasification combustion system 1 includes a garbage feeding bin 5, a garbage drying bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com