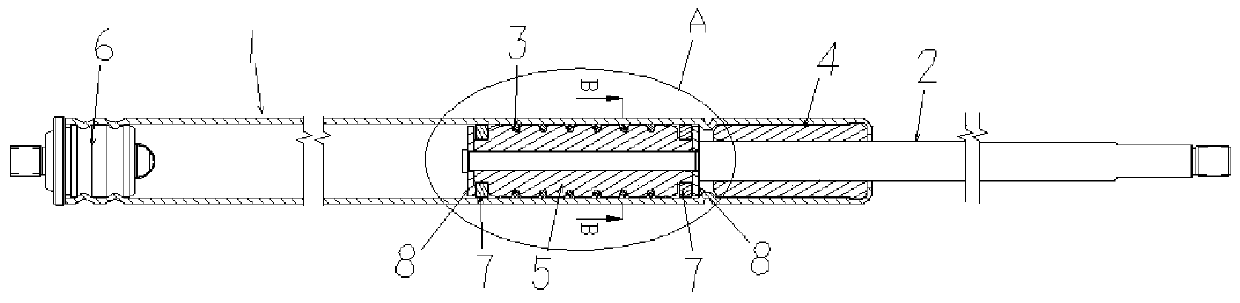

Bidirectional mechanical friction damper

A technology of mechanical friction and damper, which is applied in the direction of mechanical equipment, shock absorbers, shock absorbers, etc., can solve the problem of sealing, the structure of arbitrary stop gas spring is complicated, and the manufacturing cost is high, so as to achieve low manufacturing cost and no sealing Sexual requirements, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

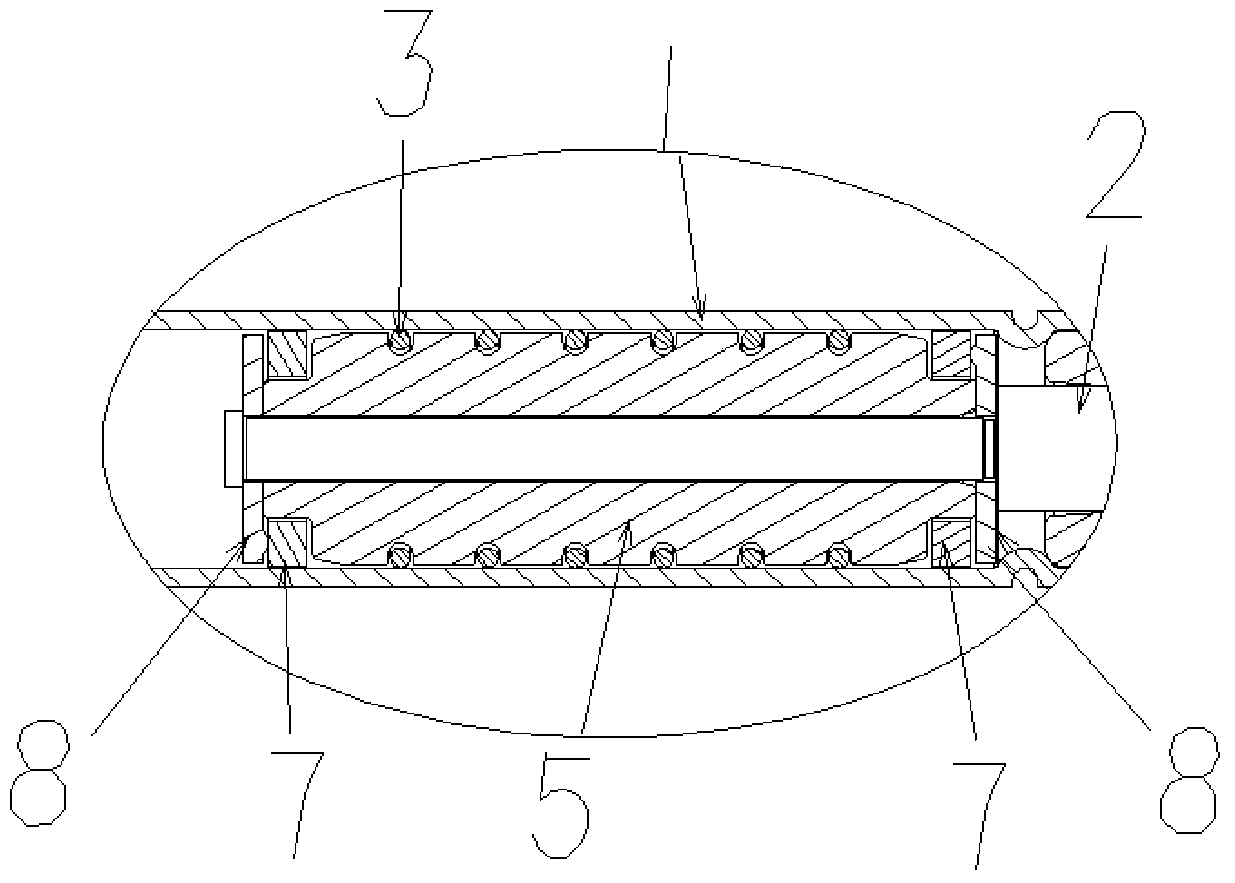

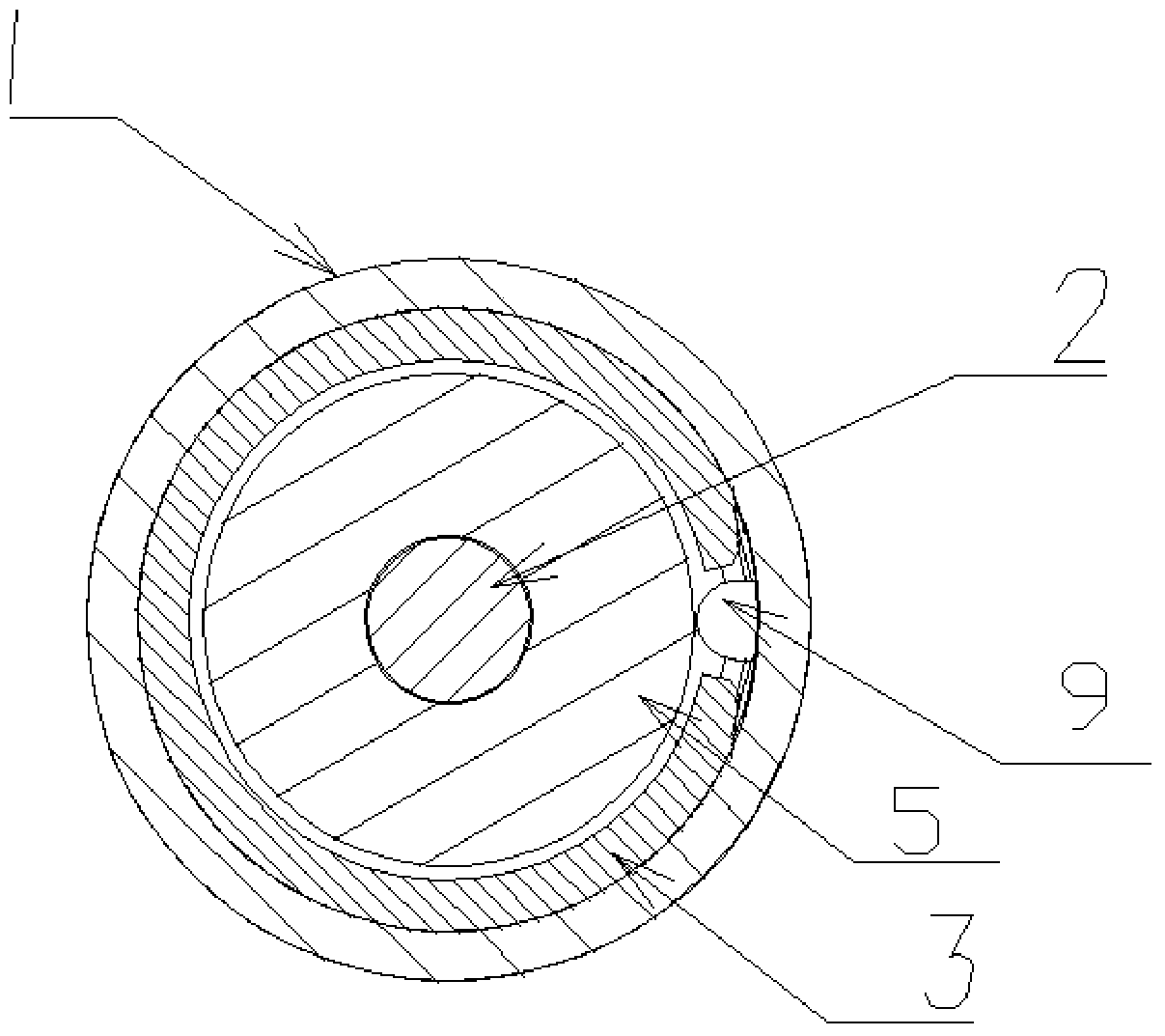

[0020] Embodiment: a kind of two-way mechanical friction damper, comprises piston cylinder 1, piston rod 2, piston and elastic body 3, and described piston rod 2 axially can slide setting distance and is inserted in piston cylinder 1, and piston rod 2 One end that is always located in the piston cylinder 1 is provided with a piston, and at least one elastic body 3 is arranged on the outer wall of the piston circumference, and the elastic body 3 is elastically pressed against the inner surface of the piston cylinder 1. The working principle: the elastic body 3 is installed in the piston cylinder 1 At this time, the elastic body 3 has a certain positive pressure on the inner wall of the piston cylinder 1. When the piston rod 2 is pulled and pressed, a certain frictional resistance will be generated between the elastic body 3 and the inner wall of the piston cylinder 1. The direction of the frictional resistance is opposite to the movement direction of the piston rod 2, and its si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com