Additive of urea-formaldehyde resin adhesive for artificial board and preparation method of adhesive

A technology of urea-formaldehyde resin and adhesive, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of difficult to ensure the pre-compression of urea-formaldehyde resin adhesives, serious environmental pollution, and formaldehyde in wood-based panels. Large amount of release and other problems, to achieve the effect of reducing formaldehyde release, simple production method, important economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

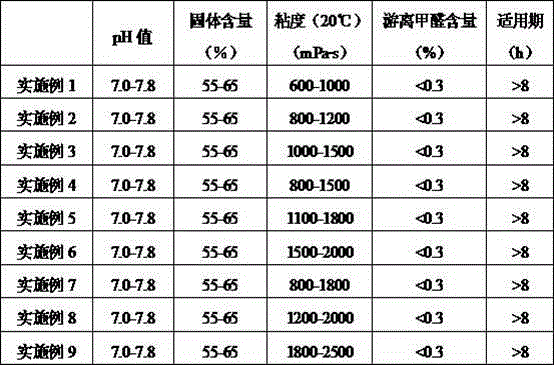

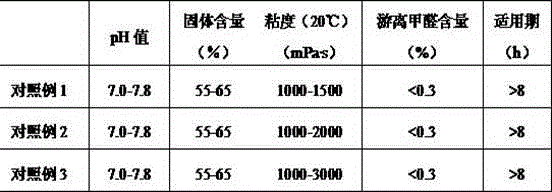

Examples

Embodiment 1

[0037] 1) Prepare materials according to the following proportions by weight (unit: kg):

[0038] Carboxymethyl sweet potato dregs 100, cassava dregs 20, corncob dregs 50, sepiolite powder 20, melamine waste 10.

[0039] 2) Mix the raw materials uniformly according to the above ratio to prepare the urea-formaldehyde resin additive of the present invention.

[0040] The quality index of the prepared urea-formaldehyde resin additive is shown in Table 1.

[0041] Exterior Bulk density (g / cm 3 ) pH value of 5% aqueous solution Moisture content (%) gray powder 0.8-1.0 7.0-8.4 5-8

[0042] The embodiment one of preparing urea-formaldehyde resin adhesive:

Embodiment 2

[0044] The additive prepared in Example 1 and the urea-formaldehyde resin were uniformly mixed at a ratio of 20:100 by weight to obtain the urea-formaldehyde resin adhesive of the present invention.

Embodiment 3

[0046]The additive prepared in Example 1 and the urea-formaldehyde resin were uniformly mixed at a ratio of 25:100 by weight to obtain the urea-formaldehyde resin adhesive of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com