Hydraulic Control System of Stationary Grabber

A technology of hydraulic control system and steel grabbing machine, which is applied in the direction of fluid pressure actuation system components, cranes, mechanical equipment, etc., which can solve the problems of inconvenient installation and driving, high maintenance cost, and high price, and achieve simple structure and safe operation , The effect of reducing the cost of daily use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

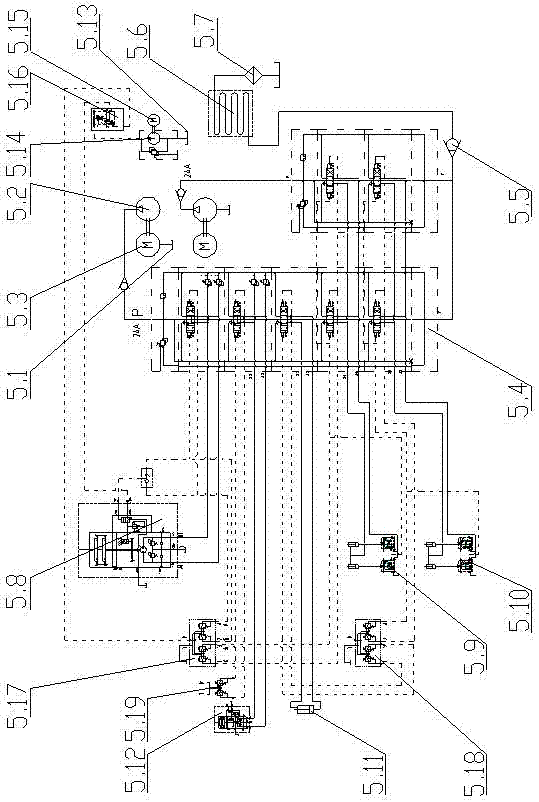

Image

Examples

Embodiment Construction

[0015] see figure 1 and figure 2 , a fixed steel grabber related to the present invention, which includes a base 1, the base 1 is fixed on the ground through an anchor rod, the base 1 is provided with a fixed seat 2, and the fixed seat 2 is A slewing platform 3 is provided on which an operating room 4 and a hydraulic station 5 are arranged. A boom 6 is also hinged on the slewing platform 3 . Between the rear part of the boom 6 and the slewing platform 3 A boom telescopic cylinder 7 is hinged, and a stick 8 is hinged at the front end of the boom 6, and a stick telescopic rod 9 is hinged between the rear part of the stick 8 and the front part of the boom 6, and the stick 8 A rotator 10 is hinged at the front end of the rotator 10, and a gripping claw 11 is arranged on the rotator 10 .

[0016] The operation chamber 4 is provided with a first joystick, a second joystick and a third joystick.

[0017] A hydraulic control system of a fixed steel grabbing machine includes a hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com