A multifunctional 3D printing head

A printing head and multi-functional technology, applied in the field of 3D printing manufacturing, can solve problems such as difficult nozzle clogging, achieve flexible and convenient replacement, meet printing accuracy, and facilitate cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to further understand the content of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings.

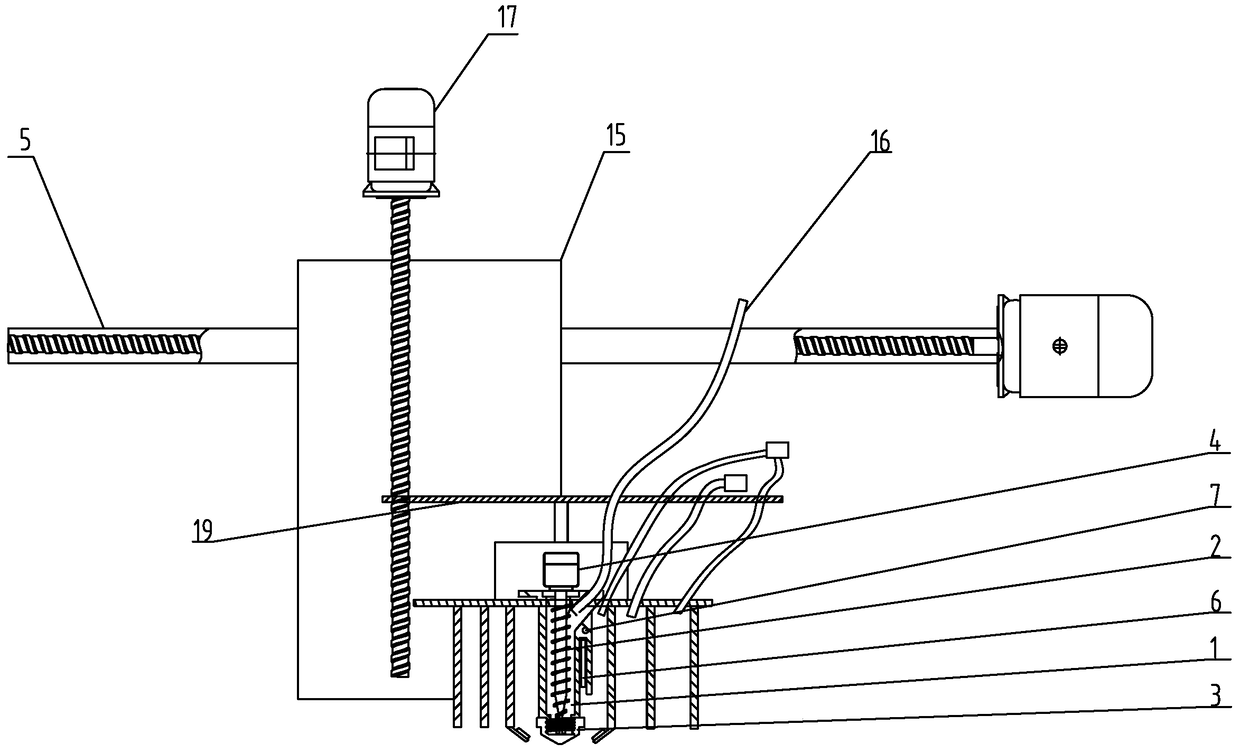

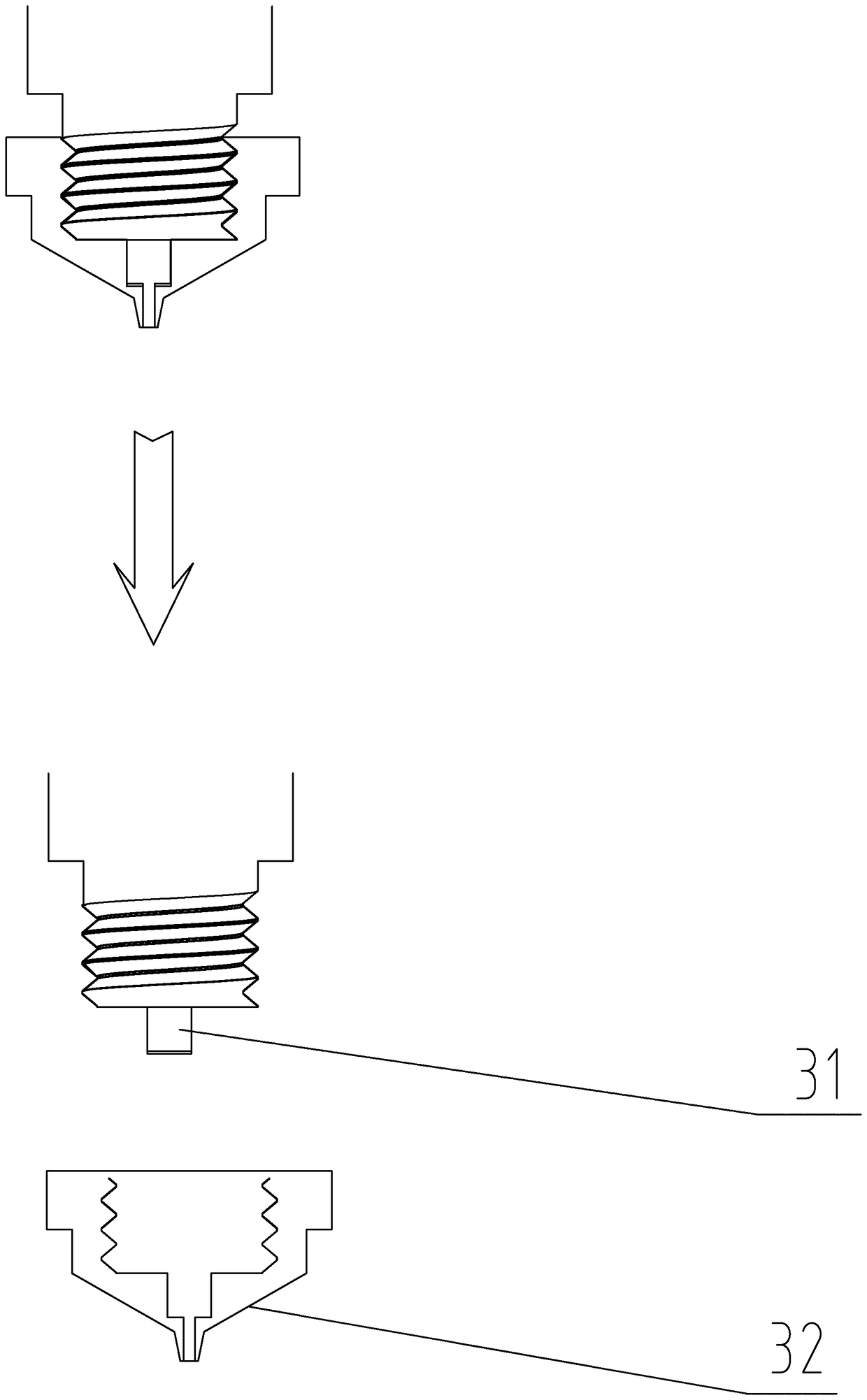

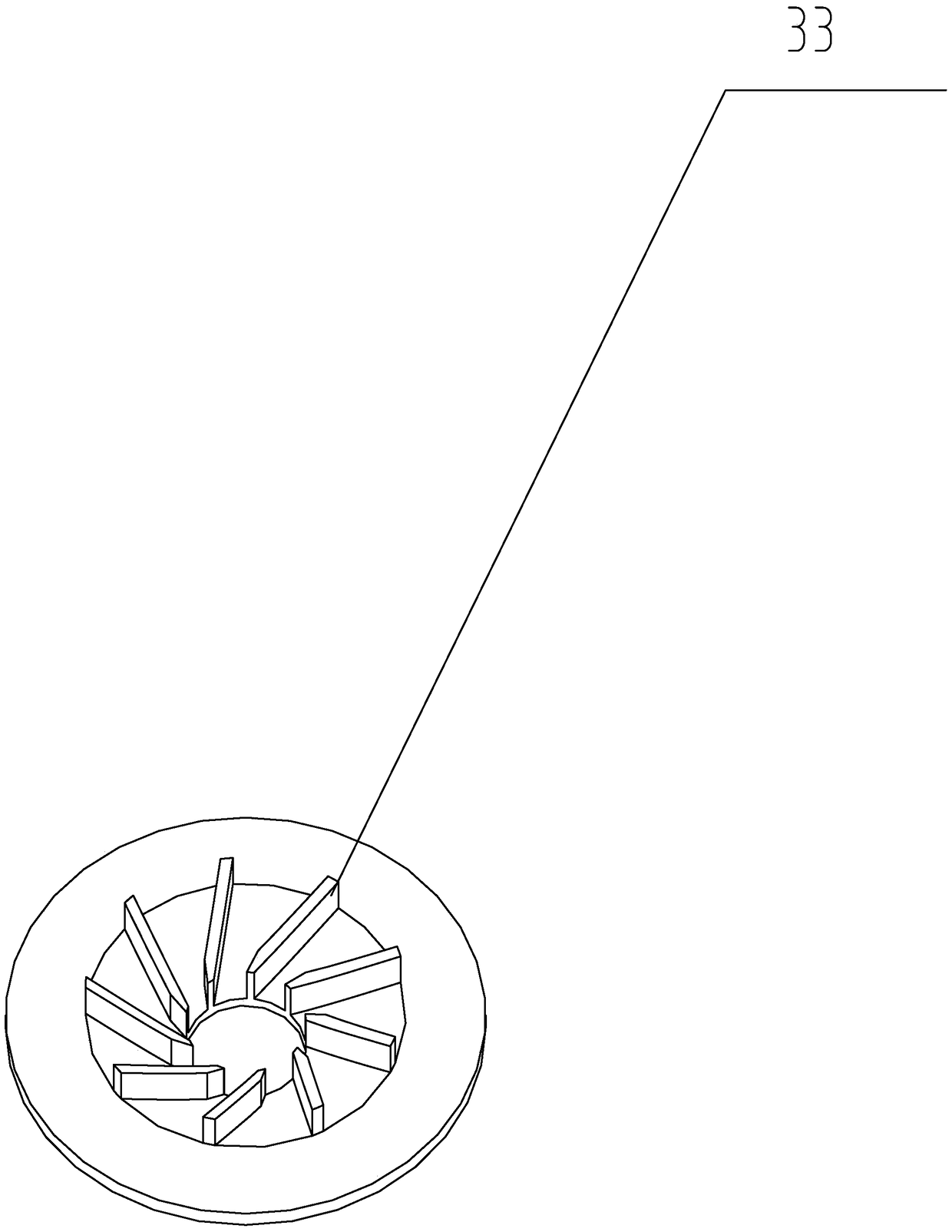

[0048] A multifunctional 3D printing head, including: hot melt chamber 1, extrusion pump 2, double socket nozzle 3, hot air grinding and cold air shaping device ( Figure 4 ).

[0049] A Z-axis lifting platform 15 is set up on the 3D printer frame, and a fixed frame 19 is arranged on the screw rod connected by a Z-axis motor 17 on the Z-axis lifting platform 15, and a multifunctional 3D printing head is connected.

[0050] One end of the elastic high-temperature resistant smooth hose 16 is connected to the top of the hot-melt cavity 1, and the other end of the elastic high-temperature-resistant smooth hose 16 is fixed on the frame on top of the X-axis Y-axis frame 5 of the 3D printer. One side of the hot-melt cavity A heating device 6 and a temperature sensor 7 are provided.

[0051] The extruding pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com