Automatic shaft feeding and rolling structure in continuous die

A reel and shaft feeding technology, which is applied in the field of mold manufacturing, can solve problems such as low efficiency, achieve convenient operation, improve work efficiency, and change the processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

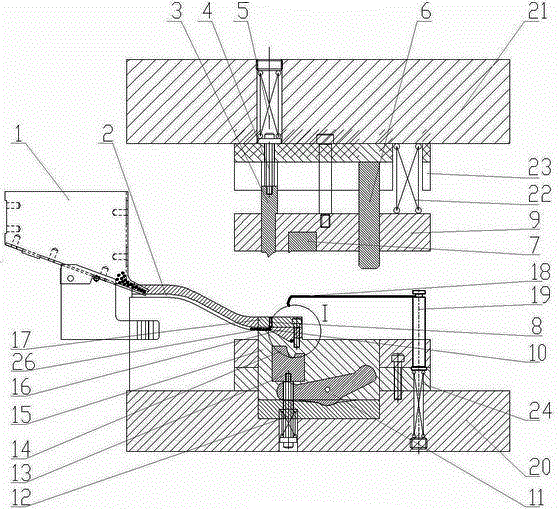

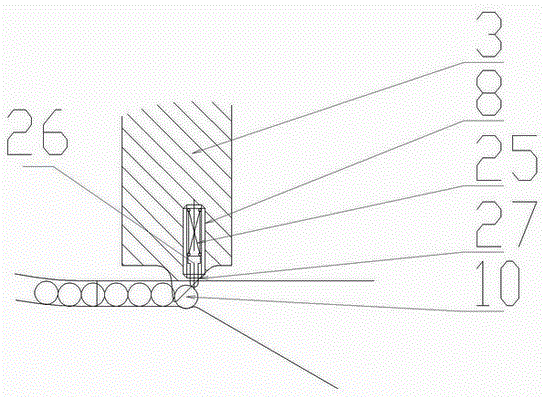

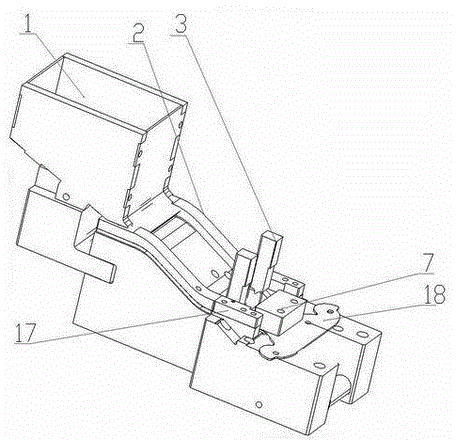

[0013] Such as figure 1 , figure 2 , image 3 As shown, the upper mold stripping plate 9 of the present invention is connected with the upper mold 21 through the spring two 22, and the upper mold stripping plate 9 is inlaid with a stripping plate insert 7; On the die 21; the push rod 3 is connected with the upper die 21 by a contour screw-4, a spring-5, and the bottom of the push rod 3 has a slope 27 for promoting the shaft 10.

[0014] The sheet metal part 18 is connected to the lower mold 20 through the spring three 24 through the floating material pin 19; the ejector pin installation block 17 is connected to the shaft placement groove 15 through the shaft stopper 16, and the ejector pin installation block 17 and the shaft stopper 16 are respectively two , symmetrically fixed on both sides of the shaft 10; the ejector pin 8 is fixed by threads in the ejector pin mounting block 17, the ejector pin 26 in the inner hole of the ejector pin 8 is connected with the ejector pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com