Dehumidifying and mildew-proof drying agent for indoor environment and preparation method of dehumidifying and mildew-proof drying agent

A desiccant and anti-mildew technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems that cannot meet market demand, poor drying performance, easy to breed mold, etc., achieve super dehumidification and anti-mold performance, excellent Hygroscopic performance, the effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

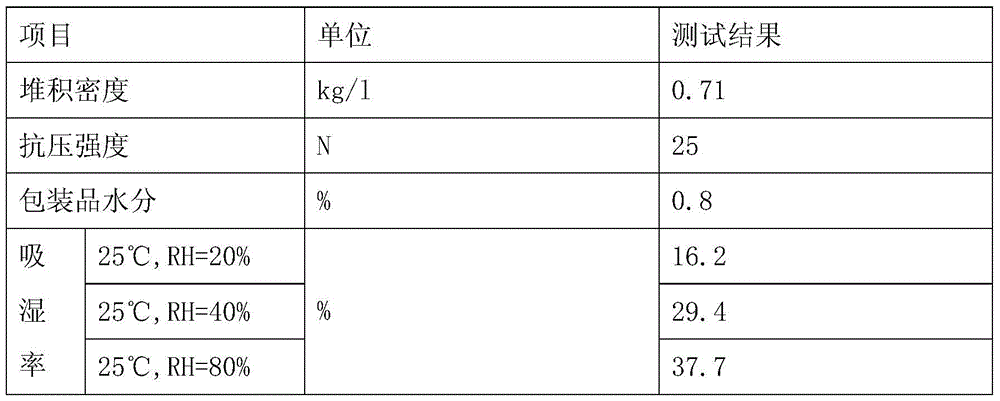

Image

Examples

Embodiment Construction

[0016] An indoor dehumidifying and anti-mold desiccant, made of the following raw materials by weight (kg): montmorillonite 17, illite 15, yellow phosphorus slag 18, tuff 12, bone charcoal powder 7, calcium propionate 5, metaluminite Sodium acid 7, titanium dioxide 9, plant ash 6, modifier 86;

[0017] The preparation method of described modifying agent is as follows: a, get the raw material of following weight (kg): konjac glucomannan 7, polyvinylpyrrolidone 5, hydroxyethyl methylcellulose 4, hydroxypropyl xanthan gum 6, Alginate triethanolamine salt 4, acrylic acid 55, potassium persulfate 0.25, N, N-methylenebisacrylamide 0.04; b, konjac glucomannan, polyvinylpyrrolidone, hydroxyethyl methylcellulose, hydroxypropyl Base xanthan gum and alginate triethanolamine salt are mixed evenly and then added to acrylic acid, stirred and swelled for 2 hours under nitrogen protection, then potassium persulfate and N,N-methylenebisacrylamide are added, and stirred evenly.

[0018] A meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com