Anti-electromagnetism wind power generator rotor

A wind turbine, anti-electromagnetic technology, applied in wind power generation, magnetic circuit rotating parts, electromechanical devices, etc., can solve the problem that the rotor can not effectively prevent electromagnetic, can not meet the needs of customers, etc., to achieve good electromagnetic shielding performance, absorption Loss, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

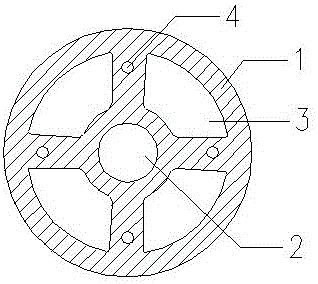

[0015] see figure 1 , an anti-electromagnetic wind power generator rotor related to the present invention includes a stator body, and the stator body is formed by continuous stacking and pressing of a plurality of silicon steel sheets 1, and the silicon steel sheet 1 is an annular structure with a central hole 2 , four fan-shaped grooves 3 are evenly arranged on the annular area of the silicon steel sheet 1, the central angle of the fan-shaped groove 3 points to the center of the center hole 2, and the annular area between the adjacent fan-shaped grooves 3 is provided with a Mounting hole 4.

[0016] The surface of the silicon steel sheet 1 is coated with an anti-electromagnetic coating, and the anti-electromagnetic coating contains polymethyl methacrylate resin as a matrix material and mesoporous carbon CMK-3 as a filling material, and the mesoporous carbon CMK-3 The filling amount of -3 is 14 to 40 wt%, wherein the mass percentage is based on the total mass of polymethyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com