Multilayer integrally-formed anti-dazzle optical diffuser plate

A light diffusion plate and anti-glare technology, which is applied in optics, optical components, instruments, etc., can solve the problems of multiple processes, high production costs, and damage to environmental modeling, and achieve excellent performance, better weather resistance, and anti-glare effects Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

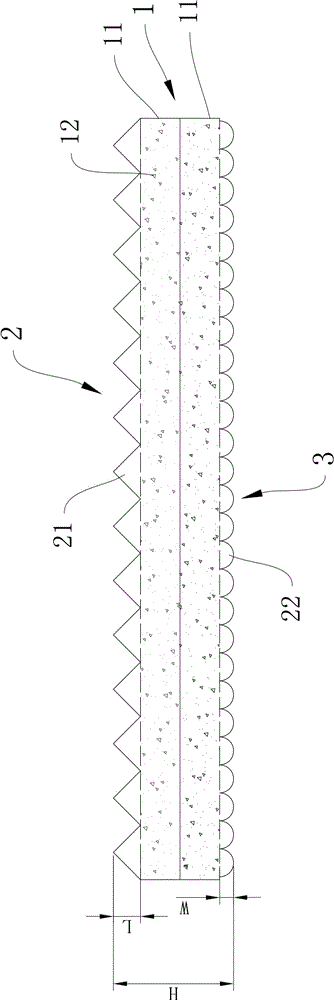

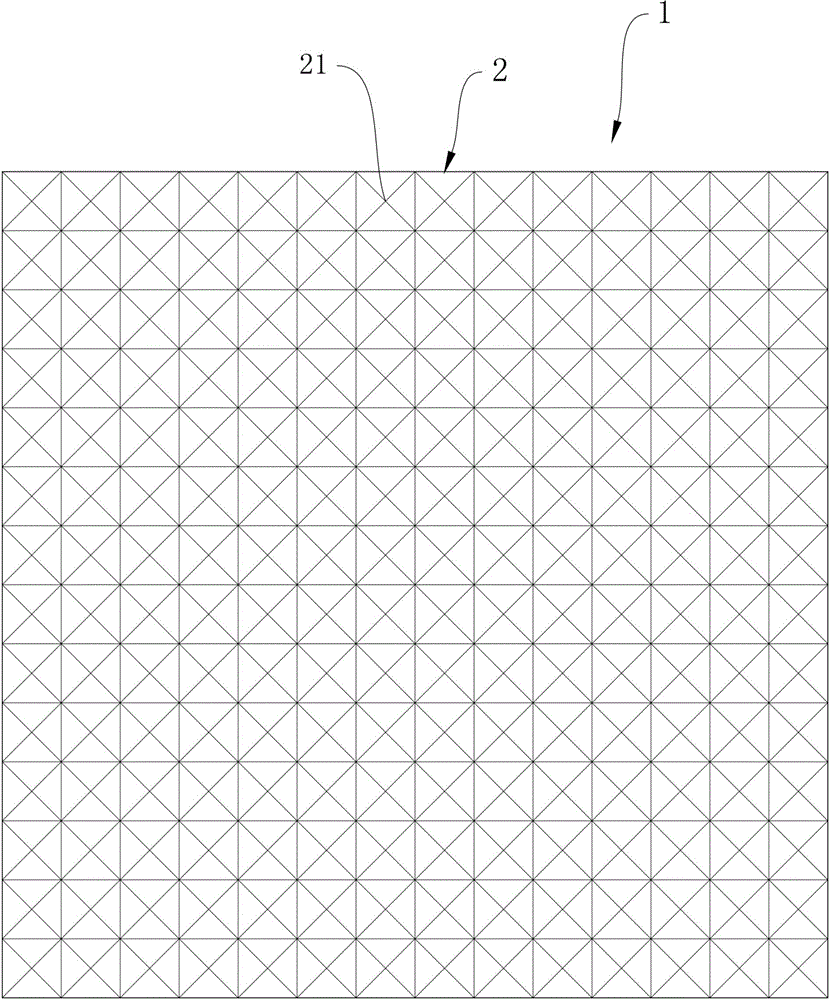

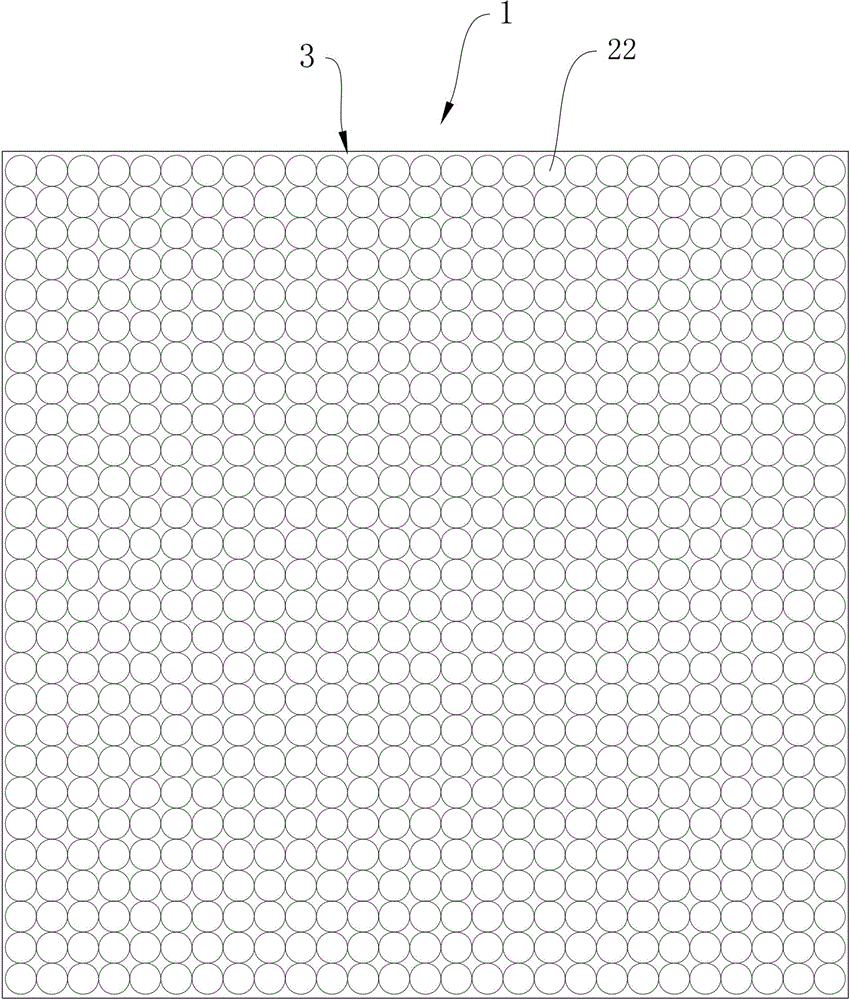

[0017] Such as figure 1 , figure 2 , image 3 As shown, the multi-layer integrally formed anti-glare light diffusion plate of the present invention includes a light diffusion plate body 1, the light diffusion plate body 1 is formed by integral co-extrusion, and at least two layers of optical properties are different from each other. The light-diffusing layer 11 is formed, and the thickness H of the entire light-diffusing plate body 1 is 0.5-6 mm, so as to achieve a better balance between its optical performance and cost. The top surface of the light diffusion plate body 1 is the light exit surface, and the light exit diffusion structure layer 2 formed by co-extruding and extending the light diffusion plate body 1 is also provided on the light exit surface, and the bottom surface of the light diffusion plate body 1 is the entrance surface. Light surface: the light-transmitting light-diffusing layer 11 is also provided with a light-diffusing particle structure 12 . Through t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com