Reversed phase high performance liquid chromatography method for determining content of dibenzyl disulfide in insulating oil

A technology of dibenzyl disulfide and reverse high-efficiency liquid phase, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high cost and limited application, and achieve high repeatability, accuracy and simple operation , The effect of low price of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Specific embodiment one: a kind of reverse high performance liquid chromatography method for measuring the content of dibenzyl disulfide in insulating oil according to the present embodiment is carried out according to the following steps:

[0022] 1. Preparation of stock solution: Weigh 0.100g of dibenzyl disulfide and 99.900g of blank oil, mix and stir at a temperature of 45-55°C until dibenzyl disulfide is completely dissolved, and then turn brown Store in a grinding bottle at a temperature of 3-5°C for later use;

[0023] If the stock solution is stored at a temperature of 3-5°C, the effective time is 3 months;

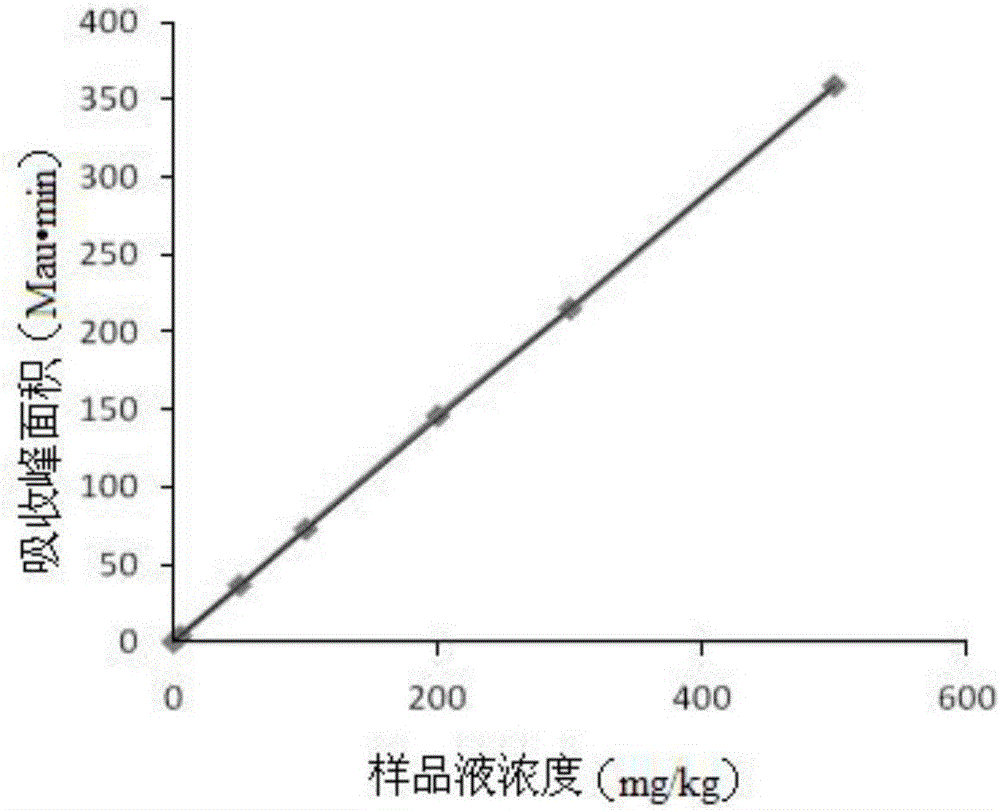

[0024] 2. Preparation of calibration solution: take five parts of the stock solution prepared in step 1, add blank oil to it and mix evenly, and prepare the concentrations as 5mg / kg, 50mg / kg, 100mg / kg, 300mg / kg and 500mg / kg calibration solution;

[0025] The valid time of the calibration solution shall not exceed 3 days;

[0026] 3. Preparation of solid-...

specific Embodiment approach 2

[0035] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: after mixing in step 1, stir at a temperature of 48-53° C. until the dibenzyl disulfide is completely dissolved. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0036] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: in step 1, after mixing, stir at a temperature of 50° C. until dibenzyl disulfide is completely dissolved. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com