Method for preparing silicon oxide/gold microsphere with surface enhanced Raman scattering effect and application thereof

A technology for surface-enhanced Raman and scattering effects, applied in the fields of material science and analytical chemistry, can solve the problems of inability to large-scale and continuous production, complicated preparation process, low production efficiency, etc., and achieve low price of instruments and equipment, and simple and easy-to-obtain raw materials. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

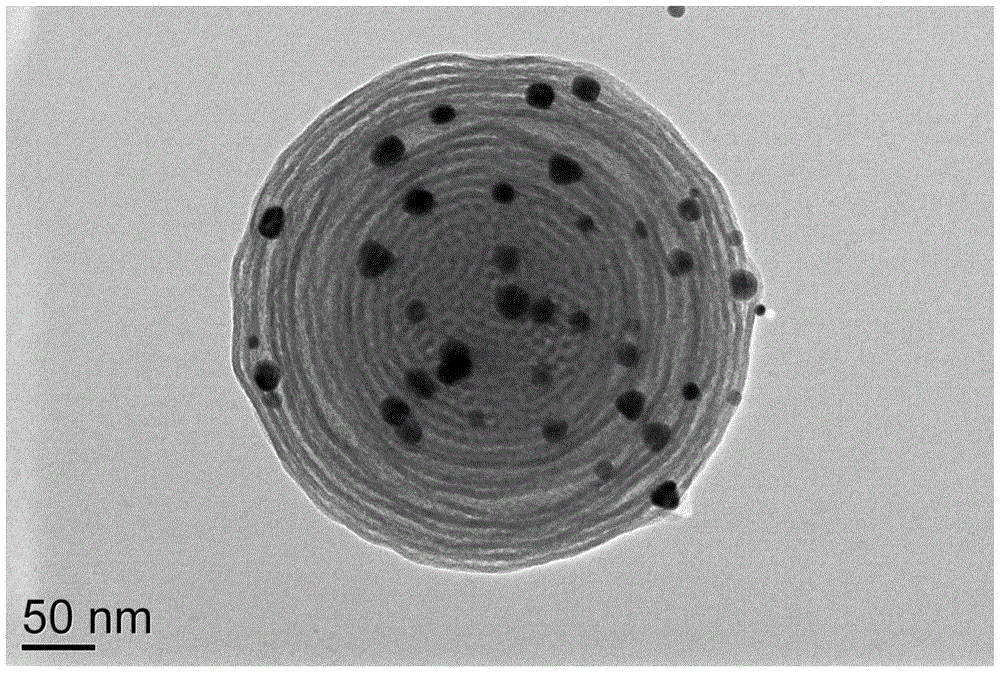

[0042] Tetraethyl Tetrasilicate, Chlorauric Acid, Surfactant Pluronic @ P123, hydrochloric acid, ethanol, and deionized water were mixed at a molar ratio of 1:0.03:0.0096:0.004:22:5 to form a precursor solution. After the above mixed solution is atomized, it is carried by nitrogen gas into a high-temperature tube furnace at a temperature of 400 degrees, and after a pyrolysis reaction, a silicon oxide / gold composite is obtained, wherein the particle size of gold nanoparticles is 5-30nm. After calcining the microspheres at 400°C for 4 hours, silicon oxide / gold microspheres with a layered mesoporous structure were obtained. figure 1 TEM image of the product.

Embodiment 2

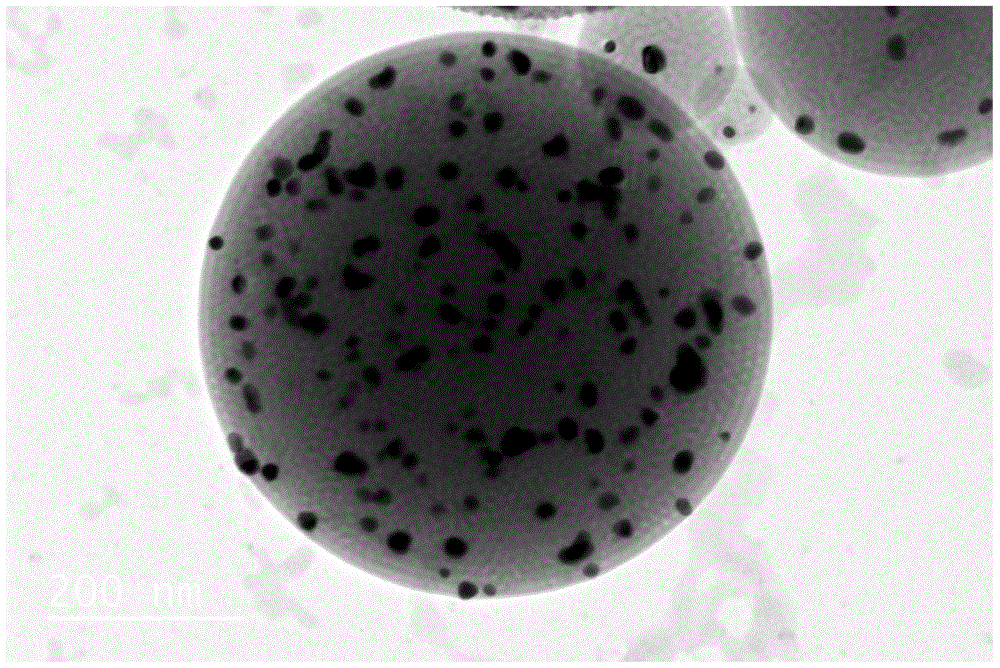

[0044] Tetraethyl Tetrasilicate, Chlorauric Acid, Surfactant Pluronic @ Mix F127, hydrochloric acid, ethanol, and deionized water at a molar ratio of 1:0.03:0.0047:0.004:22:5 to form a precursor solution. After the above mixed solution is atomized, it is carried by nitrogen gas into a high-temperature tube furnace at a temperature of 450 degrees, and after a pyrolysis reaction, a silicon oxide / gold composite is obtained, wherein the particle size of gold nanoparticles is 5-30nm. After calcining the microspheres at 450°C / 4 hours, silicon oxide / gold microspheres with a hexagonal stacked mesoporous structure are obtained, such as figure 2 Shown is a TEM image of silica / gold microspheres.

Embodiment 3

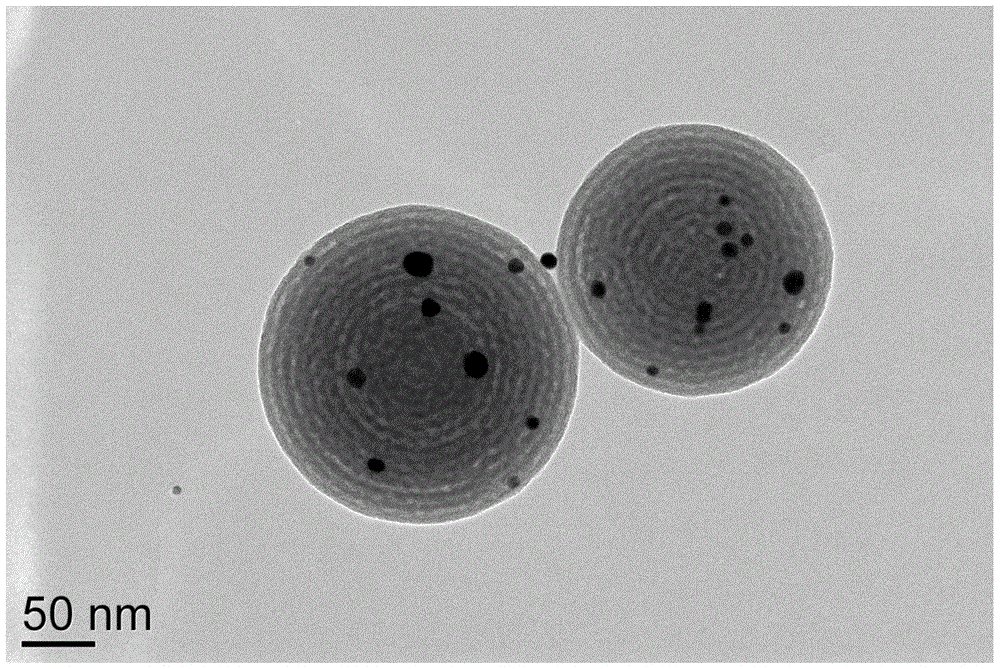

[0046] Synthetic steps are as above-mentioned embodiment one, difference is that the ratio of each reactant is tetraethyl orthotetrasilicate, chloroauric acid, surfactant Pluronic @ P123, hydrochloric acid, ethanol, and deionized water were mixed at a molar ratio of 1:0.01:0.19:0.004:22:8 to form a precursor solution. image 3 TEM image of the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| mesopore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com