A joint detection and alarm device

A technology of alarm device and marking device, which is applied in the direction of measuring devices, instruments, etc., can solve the problems affecting product qualification rate, production efficiency improvement, and production product scrap increase, so as to avoid dizziness and ensure product qualification rate and production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

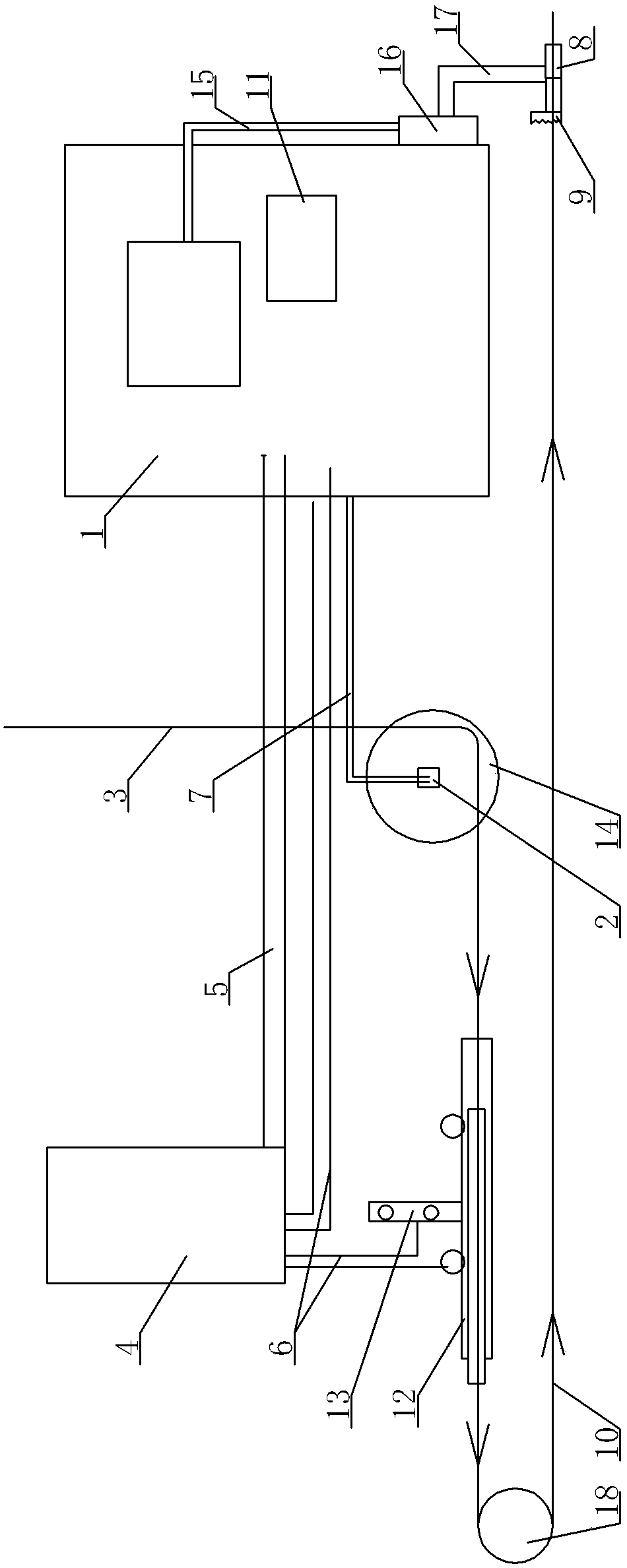

[0015] A joint detection alarm device, see figure 1 : It includes a conductor short-circuit device, a control cabinet 1, a marking device, and a length sensing device 2. One end of each semi-finished conductor 3 passes through the length sensing device 2 and is installed inside the conductor short-circuit device. The conductor short-circuit device is connected with The low-voltage power supply 4 and the low-voltage power supply 4 are connected to the control cabinet 1 through the power line 5, the conductor short-circuit device is connected to the low-voltage power supply 4 and the control cabinet 1 through the signal transmission line 6, the length sensing device is connected to the control cabinet 1 through the signal line 7, and the control cabinet 1 The output end is externally connected to the stroke cylinder 8 , the output end of the stroke cylinder 8 is connected to the marking device 9 , and the marking device 9 is arranged towards the conductor 10 to be conveyed. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com