Two-dimensional supersonic inlet of enclosed variable structure

A variable structure and air inlet technology, which is applied to jet propulsion devices, gas turbine devices, machines/engines, etc., can solve problems affecting engine performance, reduced intake air volume, and large external contraction ratio, so as to improve work efficiency and Aerodynamic performance, reduced aerodynamic resistance, highly achievable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

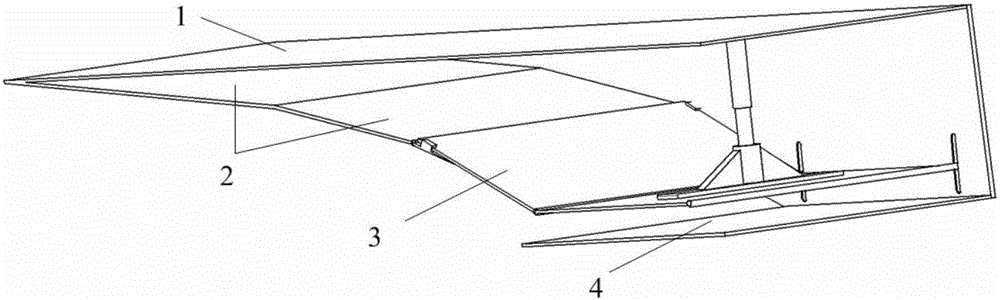

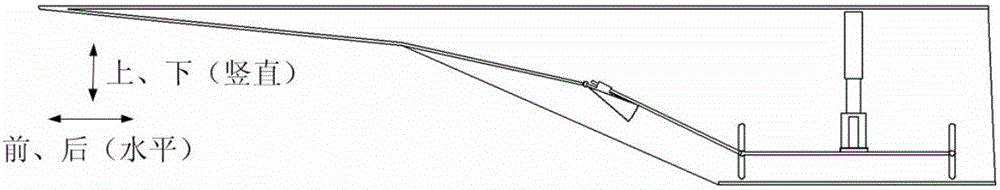

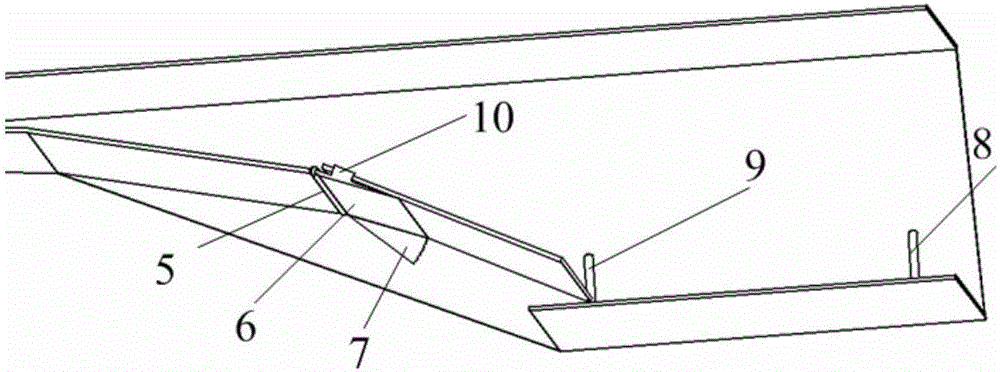

[0021] This embodiment is a closed variable structure two-dimensional supersonic inlet.

[0022] Working principle: The air inlet changes the compression angle of the movable precursor compression plate according to the flight state of the hypersonic air-breathing aircraft, so as to ensure the starting performance of the air inlet operating in a wide Mach number range and its better working state. In terms of starting performance, the intake port needs to have a sufficient shrinkage ratio to ensure the compression performance of the intake port, but if the shrinkage ratio is too large, the intake port will be blocked. At this time, change the compression angle of the movable front body compression plate, It can effectively solve the problem of shrinkage ratio; while ensuring the starting performance, it is also necessary to ensure that the air inlet is in a better working state during the working process, and sufficient compression angle can be ensured by adjusting the compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com