A reciprocating impact excavator with a rolling guide and anti-rotation assembly block that implements the rolling-guiding anti-rotation assembly block-guiding anti-rotation method

A component block and anti-rotation technology, applied in the mechanical field, can solve problems such as material waste, component deformation and damage, and space waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

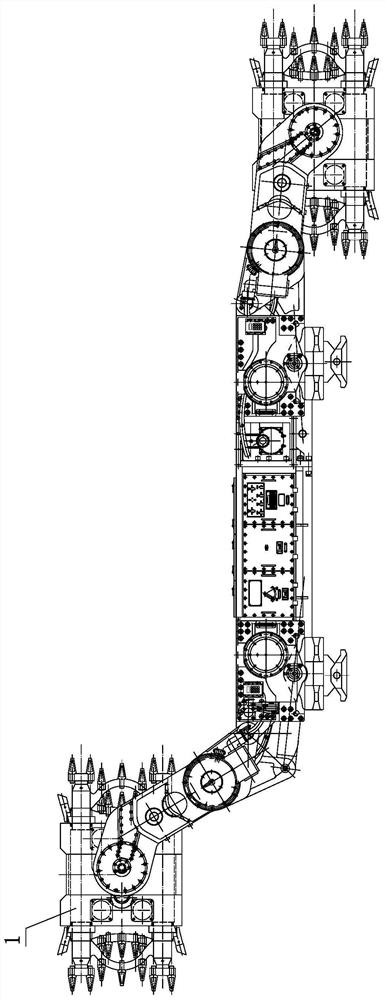

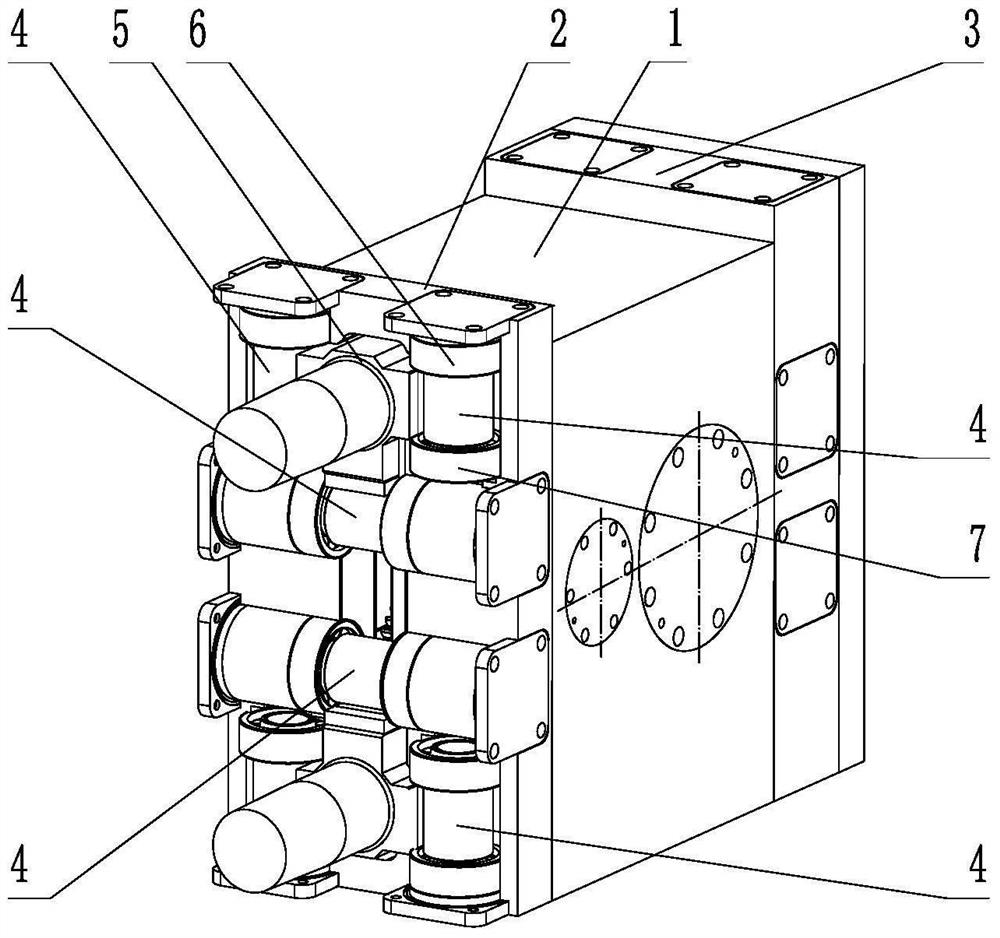

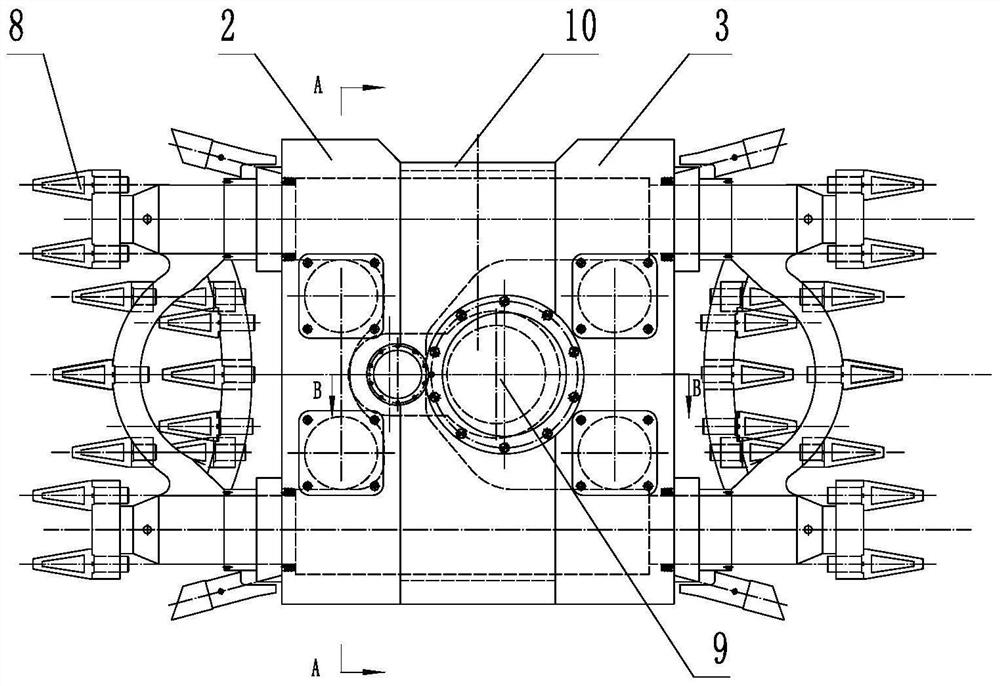

[0212] like Figure 1 to Figure 6 As shown, it is the reciprocating impact excavator equipped with rolling guide and anti-rotation assembly blocks according to the rolling guide anti-rotation assembly block guide anti-rotation method shown in Embodiment 1. The rolling guide anti-rotation assembly block reciprocating impact mining machine includes linkage guide Sealed sprocket seat 5, reciprocating power unit 9, rolling guide stopper 44, rolling guide stop assembly block 1, integrated block connector 26, guide stop box seal and reciprocating punching tooth 8, etc., interlocking guide seal The gear insertion seat 5 includes a reciprocating tooth seat interlocking section 73, a reciprocating tooth seat guiding section 33, a reciprocating tooth seat sealing section 71, a reciprocating tooth seat inserting section 72, etc. 1. The reciprocating tooth seat sealing section 71 and the reciprocating tooth seat inserting section 72 are integrated, and the front end of the interlocking gu...

Embodiment 2

[0228] like Figure 7 to Figure 11 As shown, it is the reciprocating impact excavator equipped with rolling guide anti-rotation assembly block shown in embodiment 2. The difference from embodiment 1 is that the front end of the interlocking guide seal gear holder 5 is provided with a reciprocating gear holder gear section 72. The single gear holder, the reciprocating punching gear 8 is arranged at the front end of the interlocking guide seal gear holder 5, the reciprocating power device 9 is a camshaft mechanism 17, and the camshaft mechanism 17 includes a crank connecting rod 16, etc. When the camshaft mechanism 17 is used, The crank connecting rod 16 is hinged with the interlocking guide seal pinion seat 5, and a connecting rod 282 drives a single pinion seat to form a single pinion seat reciprocating impactor. The rolling guide stopper 44 includes the roller guide stopper 11. The shaft-guided anti-rotation device 11 includes bearing A6, bearing B7 and guide roller 4, etc., ...

Embodiment 3

[0233] like Figure 12 , Figure 13 As shown, it is the reciprocating impact excavator equipped with rolling guide anti-rotation assembly block shown in embodiment 3. The difference from embodiment 1 is that the guide roller 4 is provided with bearing A inner ring stopper 42 and bearing B inner ring stopper Platform 43, etc., the diameter of bearing A inner ring stopper 42 is larger than the inner hole of bearing A6 and smaller than the inner diameter of bearing A6 outer ring, the diameter of bearing B inner ring stopper 43 is larger than the inner hole of bearing B7 and smaller than the inner diameter of bearing B7 outer ring, the inner diameter of bearing A inner ring The block 42 and the block 43 of the inner ring of the bearing B block the movement of the bearing A6 and the bearing B7 along the guide roller 4, and the rolling guide stopper 44 includes an anti-rotation part of the bearing, and the anti-movement part of the bearing includes a bearing sleeve 37 and an end Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com