Casing-associated natural gas pressure regulation and oil increase device for cluster production wells

A technology for associated natural gas and oil production wells, which is applied in the fields of fluid production, earthwork drilling, variable displacement pump components, etc. It can solve the problems of gas lock or gas lock, increase energy consumption, reduce the quantity of oil production, etc., and save time. And the inspection distance, prolong the service life, improve the output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

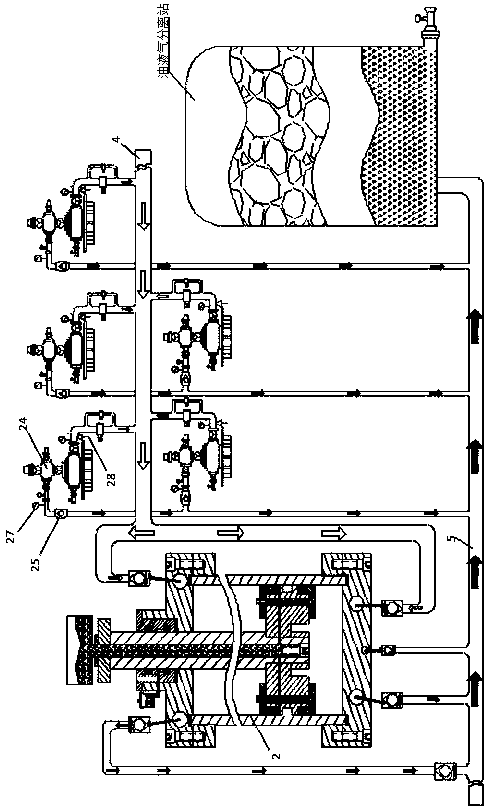

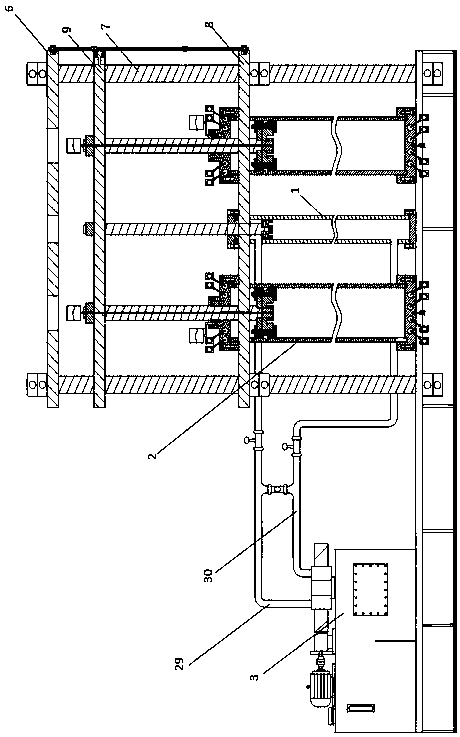

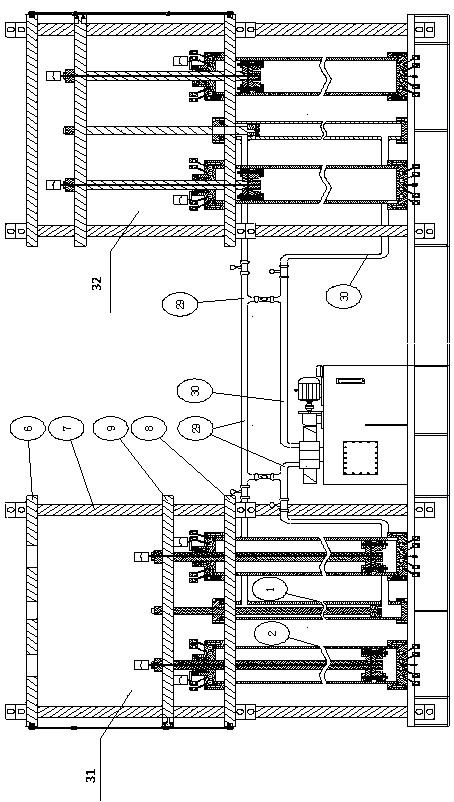

[0026] The application is further described in conjunction with the accompanying drawings. As shown in the figure, at least one set of three-beam and multi-column hydraulic two-way air intake and exhaust device has a structure such that the frame upper beam (6) and the frame lower beam (8) are fixedly installed on the guide column (7 ), the guide sliding beam (9) of the frame is flexibly connected to the guide column (7), the two-way vacuum compression pump body (2) and the hydraulic cylinder (1) are installed on the frame lower beam (8), and the two-way vacuum compression pump body The piston rod (10) of (2) and the piston rod of the hydraulic cylinder (1) are installed on the guide sliding beam (9) of the frame.

[0027] Such as figure 1 As shown, the upper cover of the two-way vacuum compression pump body (2) is designed with an upper air intake hole (11) and an upper exhaust hole (12), and the lower cover of the pump is designed with a lower air intake hole (13) and a lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com