Treatment method for large-thickness collapsible loess

A technology for collapsible loess and treatment methods, which is applied in the field of civil engineering, and can solve problems such as poor soil soaking effect, difficult construction, accurate observation of collapsible settlement, and difficulties in subsequent construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

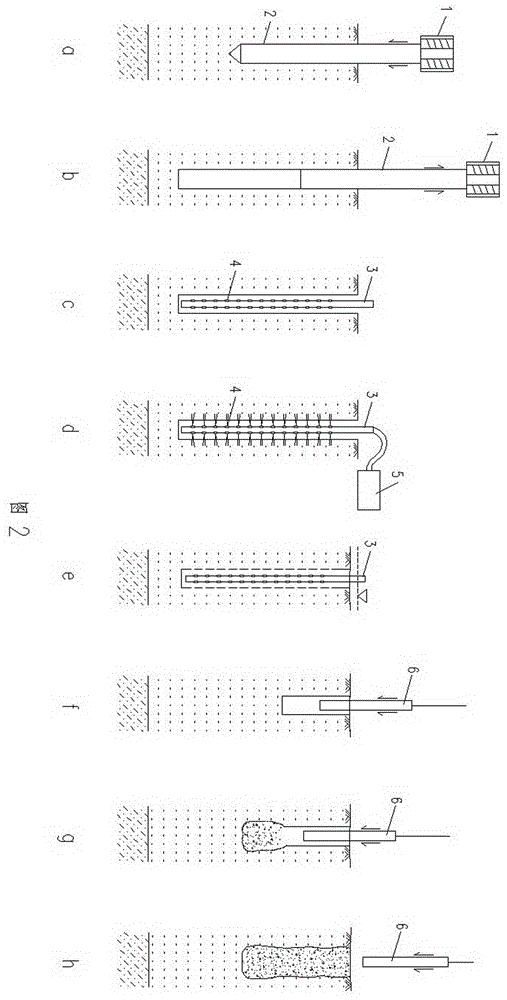

[0023] figure 1 It is a process diagram of an embodiment of the processing method of a kind of large thickness collapsible loess of the present invention, at first, as figure 1 As shown in middle a, in the collapsible loess stratum with a thickness of 36m, the casing 2 with a diameter of 30cm is sunk by hammering with the weight 1, and a prefabricated pile point is added to the bottom of the casing 2 when sinking , the sinking depth of casing 2 is 35m; then, if figure 1 As shown in middle b, a PVC water injection pipe 3 with a diameter of 20 cm and a length of 35.5 m is inserted into the casing 2, and the pipe body of the water injection pipe 3 has many small drainage holes 4; then, as figure 1 As shown in c, pull out the casing 2, leave the water injection pipe 3 in the formation, and form a water injection channel; then, as figure 1 As shown in middle d, water is injected into the water injection pipe 3, and the injected water penetrates into the foundation soil through th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com