Preparation method of N-substituted carboxyl polyaniline/cadmium sulfide quantum dot composite material

A composite material and polyaniline technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of poor separation effect of electrons and holes, large interface distance, low product purity, etc., and achieve easy agglomeration and extremely easy photocorrosion The effect of defect improvement, interfacial force strengthening, and high cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

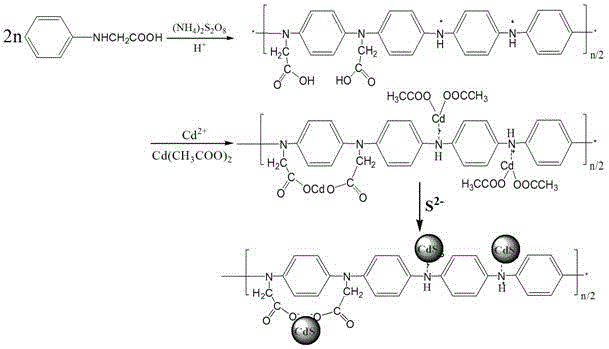

[0044] This example will illustrate the method of the present invention to generate a cadmium-containing precursor by in-situ polymerization with a molar ratio of N-phenylglycine and cadmium acetate of 1:2, and then in an ice-water bath, use the cadmium precursor and sodium sulfide nonahydrate The molar ratio is 1:1, the reaction time is 2h, and it is realized according to the reaction path of two-step synthesis.

[0045] Weigh 0.756g of N-phenylglycine and 2.66g of cadmium acetate and dissolve in 40ml of HCl solution with a concentration of 1M, and ultrasonicate for 30min until the mixed solution is dispersed to form a homogeneous solution, labeled as A; weigh 1.427g of ammonium persulfate and dissolve in In 60ml of HCl solution with a concentration of 1M, ultrasonically disperse for 5 minutes to form a uniform solution, labeled as B; in an ice-water bath, keep liquid A continuously stirring, slowly drop liquid B into liquid A, react for 6 hours, and then Leave it for 18 hour...

Embodiment 2

[0049] This example will illustrate that the molar ratio of N-phenylglycine and cadmium acetate is 1:2 in the method of the present invention to generate a cadmium-containing precursor through in-situ polymerization, and then in an ice-water bath, the cadmium precursor and nonahydrate sulfide The sodium molar ratio is 1:0.5, the reaction time is 2h, and the reaction path of the two-step synthesis is realized.

[0050]Weigh 0.756g of N-phenylglycine and 2.66g of cadmium acetate and dissolve in 40ml of HCl solution with a concentration of 1M, and ultrasonicate for 30min until the mixed solution is dispersed to form a homogeneous solution, labeled as A; weigh 1.427g of ammonium persulfate and dissolve in In 60ml of HCl solution with a concentration of 1M, ultrasonically disperse for 5 minutes to form a uniform solution, labeled as B; in an ice-water bath, keep liquid A continuously stirring, slowly drop liquid B into liquid A, react for 6 hours, and then Leave it for 18 hours, af...

Embodiment 3

[0053] This example will illustrate that the molar ratio of N-phenylglycine and cadmium acetate is 1:2, and the cadmium-containing precursor is generated by in-situ polymerization, and then in an ice-water bath, the molar ratio of cadmium acetate and sodium sulfide nonahydrate is The ratio is 1:1, the reaction time is 0.5h, and it is realized according to the reaction path of two-step synthesis.

[0054] Weigh 0.756g of N-phenylglycine and 2.66g of cadmium acetate and dissolve in 40ml of HCl solution with a concentration of 1M, and ultrasonicate for 30min until the mixed solution is dispersed to form a homogeneous solution, labeled as A; weigh 1.427g of ammonium persulfate and dissolve in In 60ml of HCl solution with a concentration of 1M, ultrasonically disperse for 5 minutes to form a uniform solution, labeled as B; in an ice-water bath, keep liquid A continuously stirring, slowly drop liquid B into liquid A, react for 6 hours, and then Leave it for 18 hours, after the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com