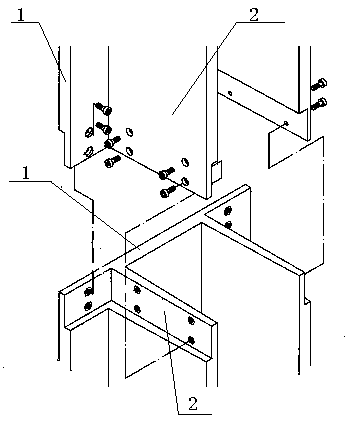

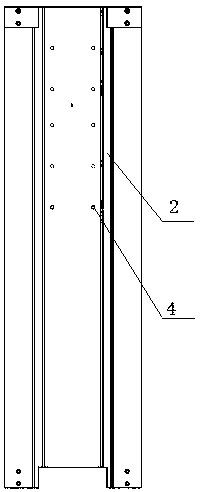

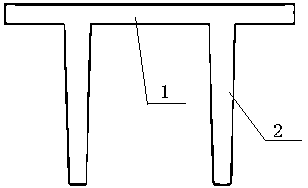

An inorganic high-performance thin-walled Π structural sheet pile for bank support and maintenance

A high-performance, structural plate technology, used in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of low strength, high brittleness, and short life, and achieve high bearing capacity, simple overall structure, and improved performance indicators. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] An inorganic high-performance thin-walled Π structural sheet pile for supporting and maintaining banks is made of inorganic high-performance fiber composite materials, and includes the following raw materials in parts by weight:

[0049] 550 parts of 42.5 cement with an average particle size of 30-60 μm; 200 parts of active admixtures with an average particle size of 0.1-10 μm and a SiO2 content ≥ 70%; 600 parts of fine aggregate with a particle size of 0.16 mm to 2.5 mm;

[0050] 300 parts of 2.5~8 mm aggregate; 30 parts of chlorine ion and sulfate-free high-efficiency superplasticizer with water reducing rate greater than 20%; 110 parts of water; 90 parts of fiber.

[0051] Wherein, described fiber comprises the raw material of following each weight part:

[0052] 55 parts of end-hook fibers with a length of 10-25 mm and a diameter of 0.15-0.5 mm;

[0053] 60 parts of corrugated copper-steel fiber with a diameter of 0.1~0.3 mm and a length of 10~25 mm; 30 parts of ba...

Embodiment 2

[0068] Except that the formula of the inorganic high-performance fiber composite material is different, the others are the same as in Example 1;

[0069] The inorganic high-performance fiber composite material includes the following raw materials in parts by weight:

[0070] 600 parts of grade 42.5 cement with an average particle size of 30-60 μm; 225 parts of active admixtures with an average particle size of 0.1-10 μm and a SiO2 content ≥ 70%; 700 parts of fine aggregate with a particle size of 0.16 mm to 2.5 mm;

[0071] 350 parts of 2.5~8 mm aggregate; 35 parts of chlorine ion and sulfate-free high-efficiency superplasticizer with water reducing rate greater than 20%; 130 parts of water; 120 parts of fiber.

Embodiment 3

[0073] Except that the formula of the inorganic high-performance fiber composite material is different, the others are the same as in Example 1;

[0074] The inorganic high-performance fiber composite material includes the following raw materials in parts by weight:

[0075] 675 parts of 42.5 cement with an average particle size of 30-60 μm; 250 parts of active admixtures with an average particle size of 0.1-10 μm and a SiO2 content ≥ 70%; 750 parts of fine aggregate with a particle size of 0.16 mm to 2.5 mm;

[0076] 400 parts of 2.5~8mm aggregate; 38 parts of chlorine ion and sulfate-free high-efficiency superplasticizer with a water reducing rate greater than 20%; 135 parts of water; 145 parts of fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com