Constant speed woven belt winding machine

A technology of braided tape and tape winding machine, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., and can solve the problems of affecting the effect of tape winding, failure to achieve automation, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

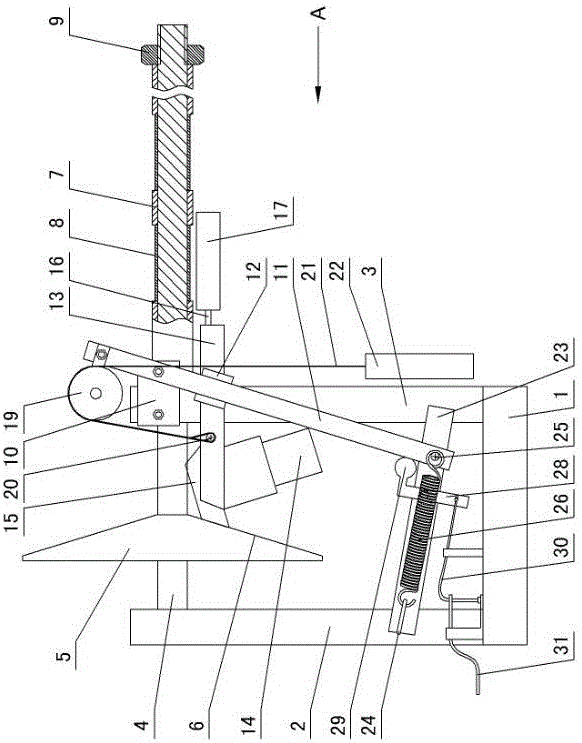

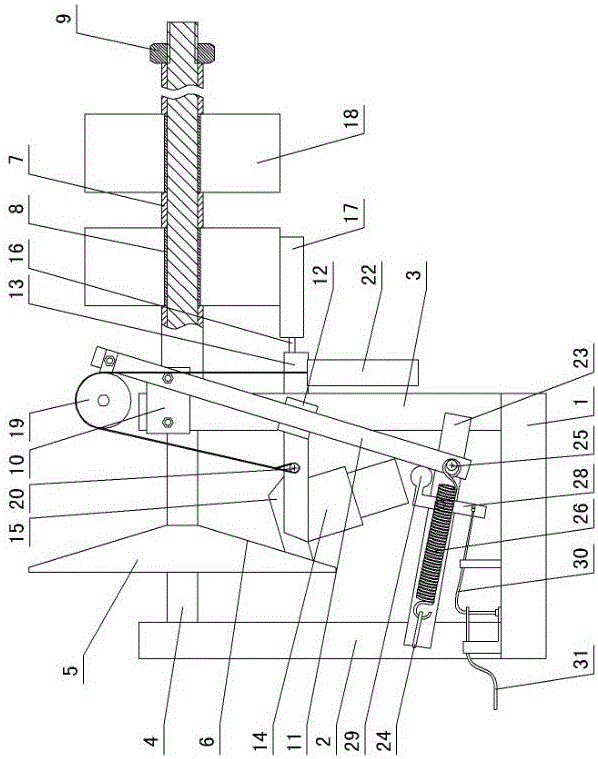

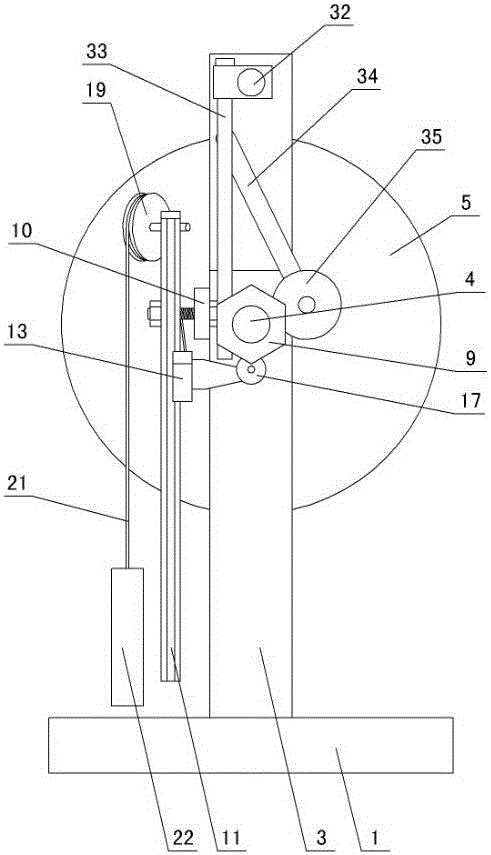

[0011] The invention relates to a constant-speed braided tape winding machine, such as figure 1 — Figure 4 Shown, it is characterized in that: comprise base 1, left support 2 and right support 3 are arranged on the base, drive shaft 4 is set between left and right support, friction wheel 5 is installed on the transmission shaft between left and right support, friction One side of the wheel is shaped on an oblique friction surface 6, and the outer wall of the transmission shaft outside the right support is provided with a compression ring 7 and a paper roll 8 at intervals, and a compression nut 9 is arranged at the end of the transmission shaft, and the compression nut is opposite to the compression ring and the paper roll 8. The paper rolls are pressed tightly, and a fixed block 10 is set on one side of the right bracket. An inclined slide rail 11 is arranged on the fixed block, and a slide block 12 is arranged on the inclined slide rail. Frame 13, fixed frame one side is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com