A fire hydrant box with convenient coiling operation

A technology with convenient operation and a fire hydrant box, which is applied in fire rescue and other fields, and can solve the problems of inconvenient winding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

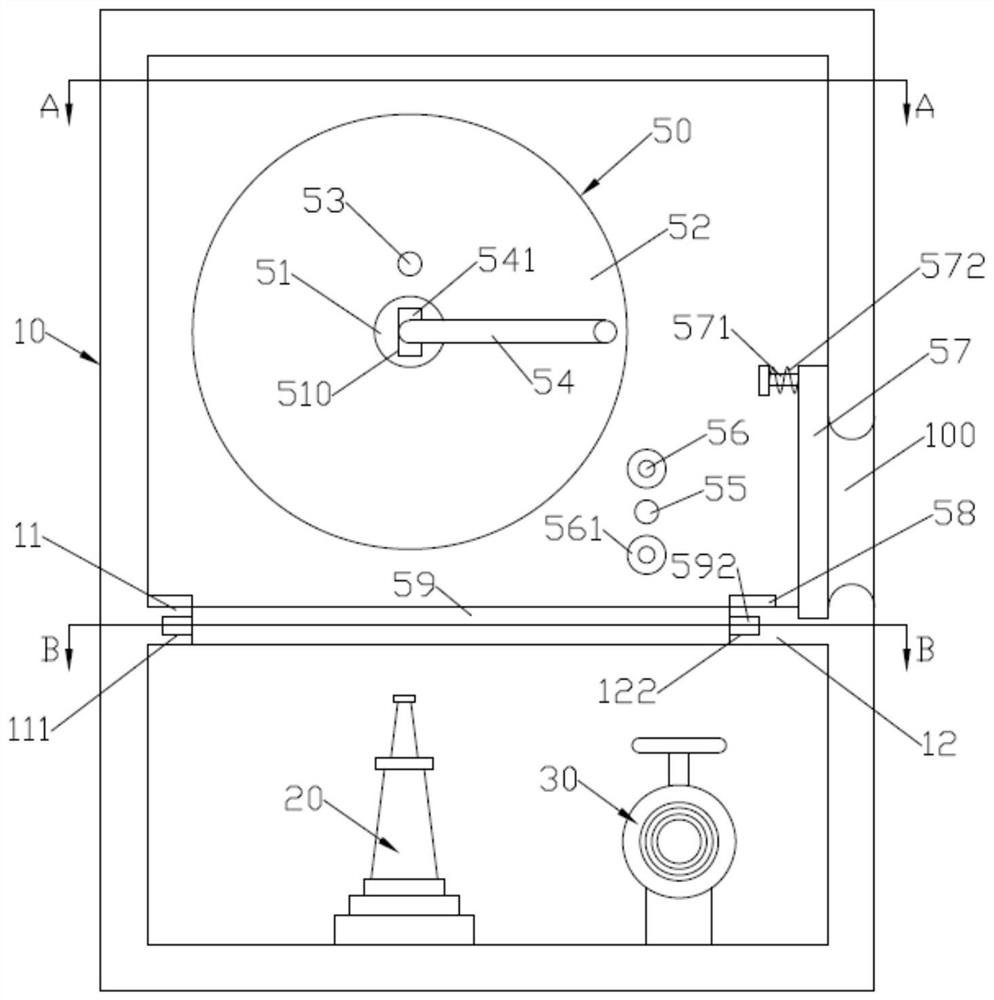

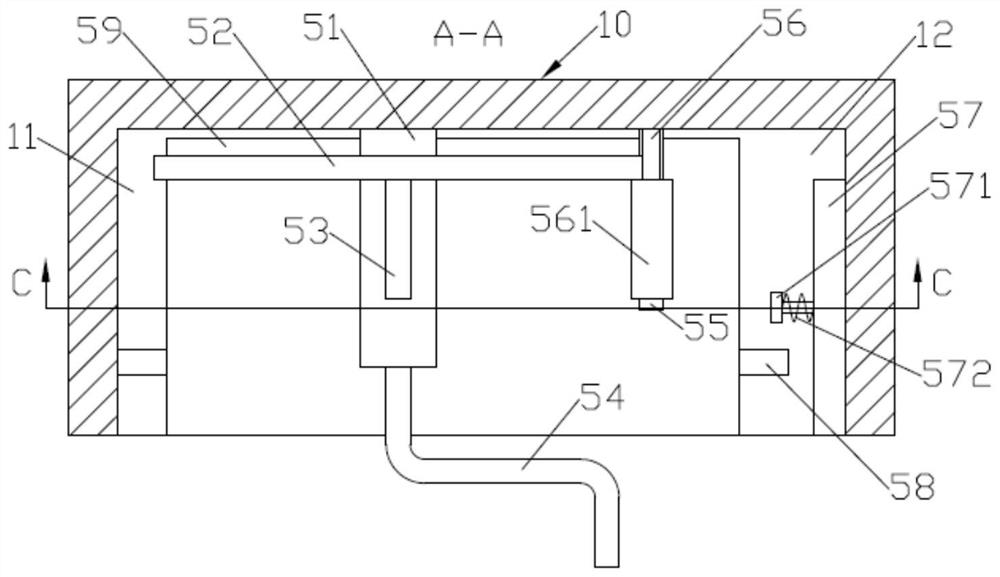

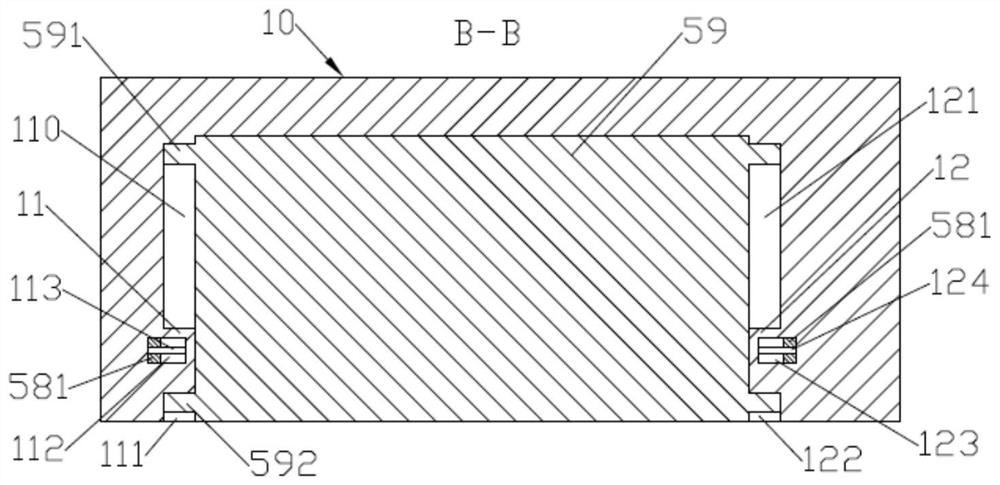

[0021] Such as Figure 1 ~ Figure 4 As shown, a fire hydrant box with convenient hose winding operation includes a box body 10, a box door, a fire hose nozzle 20, a fire hydrant head 30 and a hose winding device 50; the hose winding device 50 is arranged on the box body 10; the hose winding device 50 includes a winding central shaft 51 vertically pivoted on the rear side wall of the casing 10; the rear of the winding central shaft 51 is fixed with a rear blocking disc 52; the front end of the rear blocking disc 52 A cylindrical hose limit shaft 53 is vertically formed on the surface; a Z-shaped winding handle 54 is detachably installed on the front end of the winding central shaft 51; the rear side wall of the box body 10 is located at the lower right of the rear blocking plate 52 The position is formed with a center partition column 55 and a pair of roller center columns 56 that are evenly distributed up and down; a pair of roller center columns 56 are arranged symmetrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com